Youngstown Enterprise Incubator (YBI), an Ohio-based non-profit enterprise accelerator, has bought a Carmel 1400M Steel 3D printer from Israeli additive manufacturing OEM XJet.

The system, which leverages XJet’s NanoParticle Jetting (NPJ) expertise, might be put in at Humtown Merchandise, a YBI accomplice and America Makes member based mostly in Columbiana, Ohio.

YPI will use its new 3D printer to broaden its steel and ceramic additive manufacturing capabilities for North American prospects within the aerospace and protection, medical, and electronics industries.

“After seeing the worth and affect of XJet’s ceramic AM system, we’re excited so as to add the steel resolution to our providing,” defined Barb Ewing, CEO of YBI. “Due to its immensely precious properties, steel solely grows in reputation as a manufacturing materials and is turning into more and more necessary for a lot of of our purchasers. XJet’s unmatched high quality and backbone will allow us to ship superior manufacturing providers.”

Ewing famous that YBI’s strengthened partnership with XJet and Humtown will broaden its capacity to ship superior manufacturing capabilities throughout a wider vary of industries.

YBI grows XJet 3D printing portfolio

Based in 1995, YBI serves as a regional hub for 3D printing, giving native companies entry to superior additive manufacturing applied sciences. Its new 3D printer will complement the XJet Carmel 1400C ceramic system, which it put in in 2018.

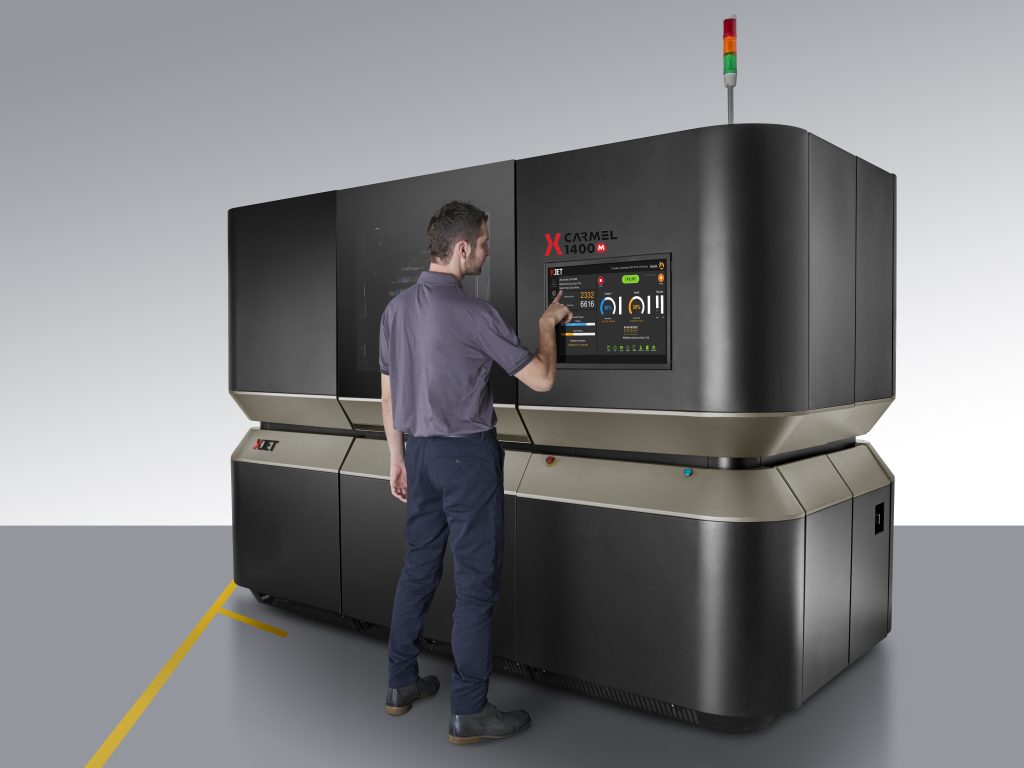

XJet initially launched the Carmel 1400M because the Carmel 3D printer in 2017. At Formnext 2019, the corporate launched two distinct platforms: one for ceramics (C) and one for metals (M).

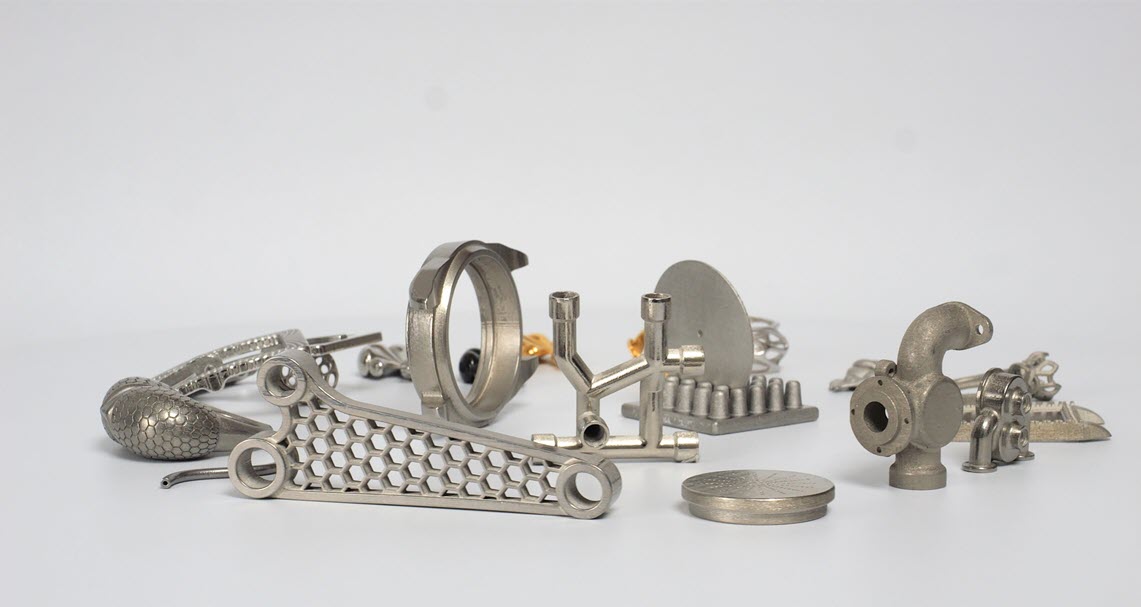

The 1400M affords a 500 x 140 mm construct space and delivers ±50 micron accuracy on elements as much as 5 mm, making it supreme for complicated functions. XJet’s proprietary NPJ expertise allows this excessive precision. NPJ is a powderless 3D printing course of that makes use of liquid nanoparticle inks to supply steel and ceramic elements.

In line with XJet, NPJ eliminates the intensive post-processing usually required throughout powder-based steel additive manufacturing. It’s also reportedly well-positioned to fabricate complicated, high-performance, and high-resolution steel elements at an industrial scale, making it supreme for purchasers within the regulated aerospace, protection, and medical sectors.

By increasing its steel 3D printing capabilities, Humtown Merchandise now affords a complete manufacturing ecosystem throughout North America. In the meantime, YBI will proceed serving as a regional expertise facilitator by way of its function in America Makes, a U.S. public-private partnership devoted to accelerating the adoption of additive manufacturing. In line with XJet, the three-way partnership positions Ohio’s Youngstown area as an rising hub for high-precision additive manufacturing.

Man Zimmerman, CEO of XJet, referred to as YBI the “excellent accomplice” to assist the corporate broaden within the U.S. market. He believes the expanded collaboration “validates the distinctive worth our AM expertise delivers and displays robust market confidence in our North American progress potential.”

Humtown Merchandise’ President and CEO, Mark Lamoncha, commented that his firm is “excited to play a component within the commercialization of one of many world’s premier nano-metal 3D printers.” He famous that the deal displays a “new course for Humtown,” providing a possibility to broaden relationships with its present buyer base and develop Youngstown’s additive manufacturing group.

“YBI’s acquisition of the XJet steel printer marks one other key ‘win’ for the Youngstown Innovation Hub for Aerospace and Protection,” added John Wilczynski, Govt Director of America Makes. “This cutting-edge expertise considerably enhances the capabilities of the area and can additional strengthen Youngstown’s presence within the aerospace and protection sectors.”

Steel 3D printing experiences rising international adoption

XJet shouldn’t be the one firm to broaden the attain of its steel additive manufacturing expertise. Australian Wire Additive Manufacturing (WAM) 3D printer OEM AML3D not too long ago bought an ARCEMY Small Version to American shipbuilder Austal USA in a deal value AU$1.2 million (USD$0.78 million).

This technique might be put in on the U.S. Navy’s Additive Manufacturing Heart of Excellence (AM CoE) in January 2026. Will probably be mounted inside a 20-foot transport container to enhance deployability and scale back field-service set up instances from 2-3 weeks to 2-3 days. AM CoE personnel will use the system to speed up expertise improvement and steel elements weighing as much as 750 kilograms.

In different information, chilly spray 3D printing firm Impression Improvements not too long ago introduced it has accomplished the set up of 100 3D printers throughout greater than 30 nations. Q2 2025 noticed the German agency ship eight new EvoCSII 3D printers, a record-breaking quarter that additional expanded the corporate’s international footprint.

Impression’s expertise will be discovered throughout Germany, the USA, China, India, Australia, and South Korea. These methods help a variety of industries, starting from aerospace and electronics to induction cookware and industrial analysis.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the most recent 3D printing information.

You can too comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits the XJet Carmel 1400M 3D printer. Picture through XJet.