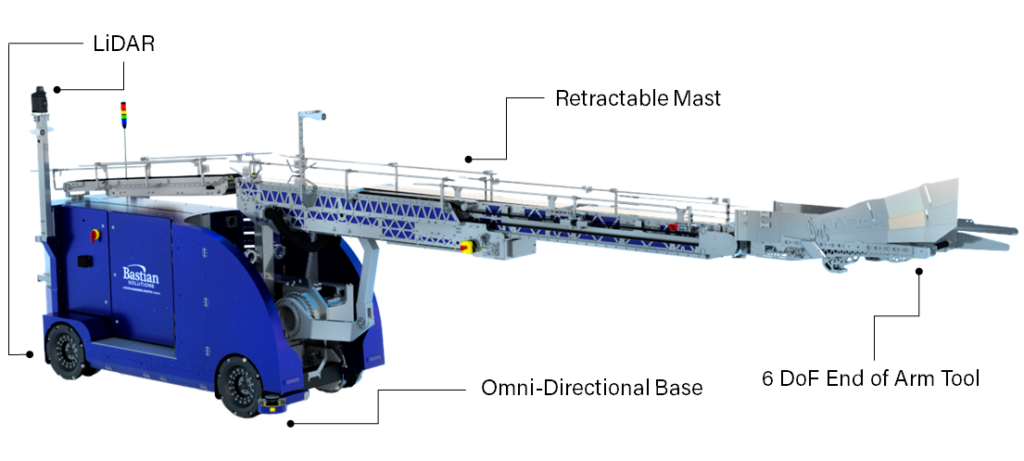

Bastian Options’ ULTRA BLUE robotic reaches right into a trailer. Supply: igus

Robotic techniques deployed in warehousing environments typically face demanding circumstances, equivalent to temperature fluctuations, the presence of mud, and fixed high-impact masses. Conventional steel machine elements — notably bearings that depend on exterior lubrication — are susceptible in these environments, resulting in extra frequent upkeep, downtime and potential contamination points.

Bastian Options, a fabric dealing with system integrator, bumped into many of those points when designing its ULTRA BLUE robotic truck-loading system. It wanted machine elements that would stand up to steady, high-cycle operation in dynamic, dust-prone environments.

The reply got here within the type of high-performance, lubrication-free movement plastics from igus.

Right here’s how the mixing of polymer merchandise — together with plain bearings, linear guides, spherical ball joints, and slewing bearings — enabled Bastian Options to enhance ULTRA BLUE’s effectivity and reliability whereas decreasing prices.

Bastian builds ULTRA BLUE to enhance warehousing security

Bastian designed ULTRA BLUE to switch guide loading of packing containers and instances into truck trailers. By automating these high-volume loading operations, this cellular system addresses the bodily calls for and security dangers related to repetitive heavy lifting in warehouses and manufacturing services.

ULTRA BLUE can autonomously navigate between a number of dock doorways with out requiring rails, in-ground tools, or different further infrastructure. Its elements embrace a retractable mast, customized end-of-arm tooling (EOAT) with six levels of freedom and articulating conveyors.

The method works like this: Bins journey from an extendable conveyor hooked up to the again of the system, then up the mast. From there, the EOAT exactly locations the packing containers contained in the trailer from the bottom up utilizing lidar navigation.

ULTRA BLUE can deal with over 1,000 instances per hour in 24/7 operations and requires solely a single operator to handle a whole fleet via a centralized management interface.

Robotic operates in demanding circumstances

In contrast to different automated loading techniques, ULTRA BLUE combines a number of capabilities right into a single, environment friendly resolution. Designing it, nonetheless, required bearings and different machine elements that would deal with the robotic’s difficult operational atmosphere. These circumstances included:

- Temperature swings: From humidity in the summertime to chilly temperatures within the winter, temperature fluctuations can influence the efficiency and lifespan of conventional steel bearings, which require specialised lubricants that may degrade beneath such circumstances.

- Mud and particles: The presence of particles and mud as a result of corrugated packing containers can result in fast put on and tear in conventional elements, necessitating frequent expensive upkeep and bearing substitute.

- Varied field circumstances: ULTRA BLUE should deal with a wide range of packages, equivalent to skinny, bowing or broken packing containers which are irregularly sealed and packaged, creating dynamic and doubtlessly high-impact masses on the inner mechanisms and bearings.

To handle these challenges, Bastian Options wanted elements that would survive the robotic’s excessive cycle instances and dusty environments for lengthy durations of time. In addition they needed to assist heavy influence masses throughout operation.

igus supplies lubrication-free resolution

As an alternative of constant to combat these upkeep battles, Bastian Options turned to igus for a strong and dependable resolution, integrating a set of the corporate’s high-performance polymer elements into ULTRA BLUE. These included:

- Plain bearings have been utilized in a four-bar linkage mechanism pushed by a cam profile.

- Linear guides assist the linkage mechanism. Bigger customized guides have been additionally added to the system’s conveyor part.

- Spherical ball joints join two conveyor sections that pivot relative to one another.

- Plain slewing bearings have been integrated as a rear pivot of a conveyor part — an space that was inclined to mess buildup.

The mix of those elements addressed ULTRA BLUE’s operational challenges and efficiency necessities. For instance, a key design function throughout all igus elements is their self-lubricating nature.

In contrast to steel bearings that demand common lubrication, igus bearings are produced from high-performance plastics that include stable lubricants embedded inside the materials, eliminating the necessity for exterior lubrication and delivering a number of key benefits:

Lowered upkeep prices and downtime. The self-lubricating nature of igus elements reduces the labor, time and related prices of routine upkeep. For ULTRA BLUE, the power to function throughout a number of shifts and cut back downtime is essential for maximizing warehousing productiveness.

Contamination prevention. In environments with particles from corrugated packing containers, lubricants can appeal to and lure particles, resulting in untimely put on and contamination. Using igus bearings prevents these points, making certain cleaner operation and lengthening part life. This function has been particularly useful for the slewing bearing utilized in a bit of ULTRA BLUE inclined to mess buildup.

Suitability for harsh environments. The flexibility to function reliably with out exterior lubricants makes igus elements appropriate for environments with temperature fluctuations, together with these during which ULTRA BLUE operates. In such circumstances, conventional greases are liable to thickening, thinning or degradation.

Parts to boost warehousing robotic sturdiness, cut back prices

Past fixing the upkeep issues, the igus elements enabled Bastian Options to scale back prices in a number of methods:

- For the four-bar linkage mechanism, switching to igus bearings not solely doubled the system’s life but in addition minimize the part price by half.

- The spherical ball joint changed a dearer bearing and eradicated the necessity for a mud boot, additional simplifying design and reducing prices.

- The elements diminished buyer upkeep labor and spare half prices.

The igus elements even improved ULTRA BLUE’s design flexibility and efficiency. For instance, a key function of the linear guides is clean, quiet operation, making the system’s operation extra environment friendly and fewer disruptive in busy warehousing environments.

Designed with exact tolerances, the spherical ball joints additionally promote dependable efficiency in dynamic purposes, together with the ULTRA BLUE, whose two conveyor sections should pivot relative to one another.

Be taught extra about lubrication-free bearings

By implementing lubrication-free plain bearings, linear guides, spherical ball joints, and slewing bearings, Bastian Options efficiently met the operational and efficiency necessities for its ULTRA BLUE warehousing robotic.

To be taught extra about how igus elements can profit your robotic utility, go to: www.igus.com.