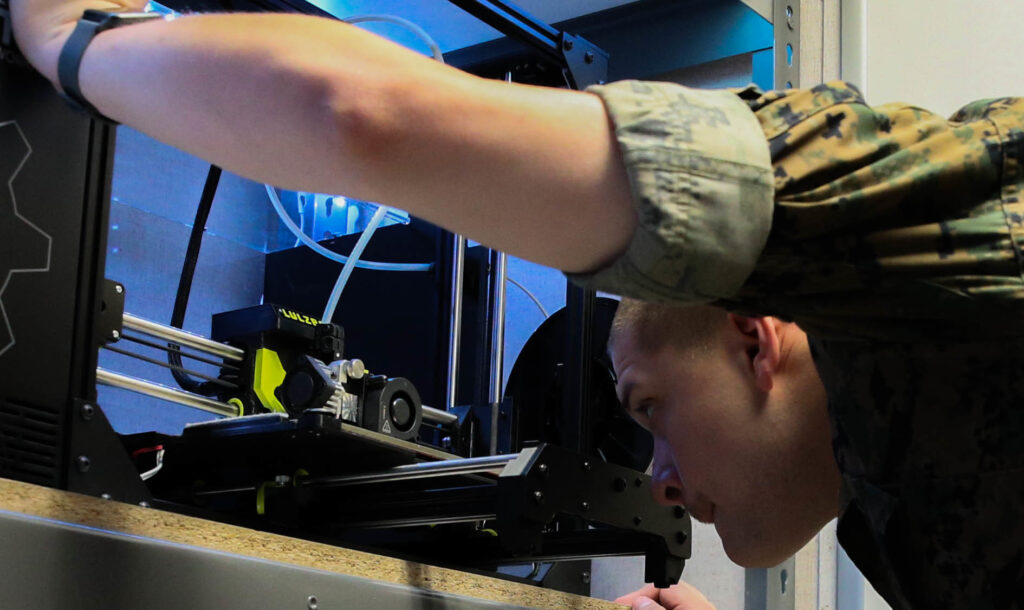

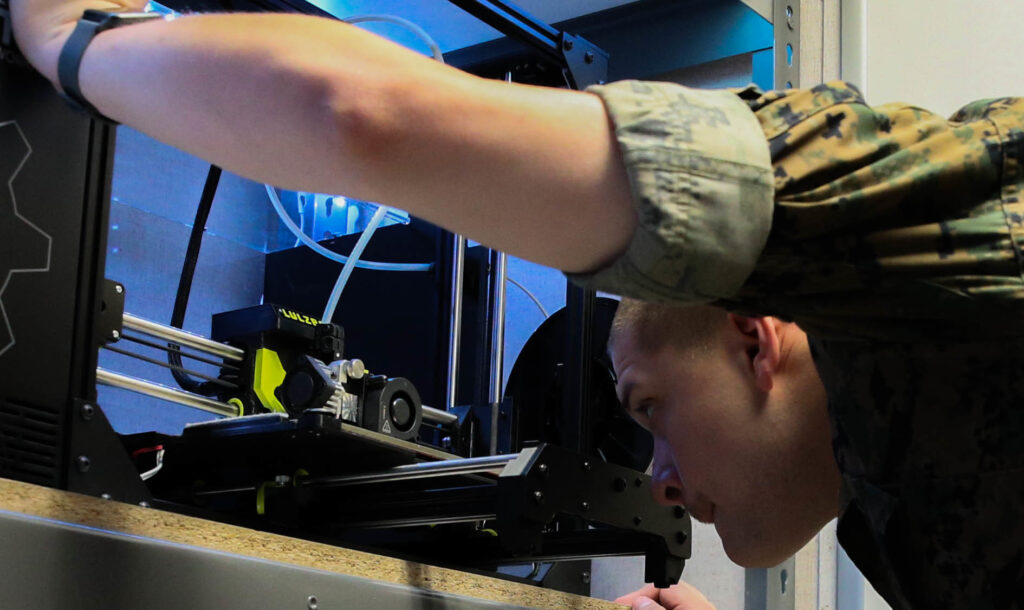

The US army is analyzing 3D printing expertise as an answer for frontline gear repairs. Throughout a latest congressional listening to on army spending, Chairman of the Joint Chiefs Gen. Dan Caine acknowledged that “the drive of the long run will repair on the spot.” This strategy goals to cut back the observe of cannibalization, the place components are harvested from some gear to restore others.

Logistics challenges are notably vital in potential Pacific conflicts, the place huge distances between island chains create provide difficulties. The Division of Protection is exploring choices for troops to supply vital components instantly at ahead positions with out entry to established upkeep services. This functionality may very well be vital in eventualities the place conventional provide chains are disrupted or impractical.

“I’m actually inspired by the innovation that’s occurring to have a look at issues like additive manufacturing, the place we come up with the specs from firms like Lockheed and others,” Caine stated, “and may simply 3D print proper on the spot the requirement.” The army has been testing 3D printing expertise for years, together with latest concrete-based printing tasks at Fort Bliss, Texas.

Related purposes are already showing in battle zones worldwide. In Myanmar, insurgent fighters have used 3D printers to fabricate weapons components, whereas Ukrainian forces have printed parts for improvised units. These real-world implementations exhibit the expertise’s potential utility in fight conditions.

The effectiveness of battlefield 3D printing will in the end rely upon sensible issues like velocity and portability. Present industrial 3D printing processes can take days to finish, which will not be possible in fight eventualities. If the gear proves too sluggish or cumbersome, troops may revert to conventional restore strategies regardless of the technological potential.

Supply: businessinsider.nl