Dyndrite, a software program firm specializing in GPU-accelerated digital manufacturing instruments, has signed a multi-year licensing settlement with aerospace propulsion agency Ursa Main. The settlement follows a six-month technical analysis by which Dyndrite’s LPBF Professional software program surpassed Ursa Main’s current toolchain. The software program will now help Ursa Main’s metallic additive manufacturing operations, together with materials growth, half qualification, and the manufacturing of rocket engines for protection, hypersonic, and industrial house purposes.

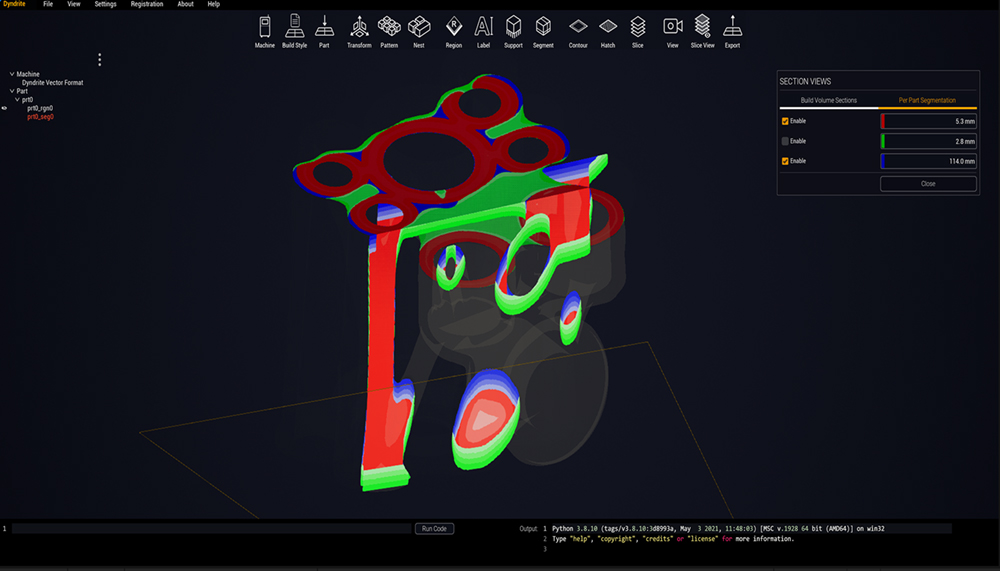

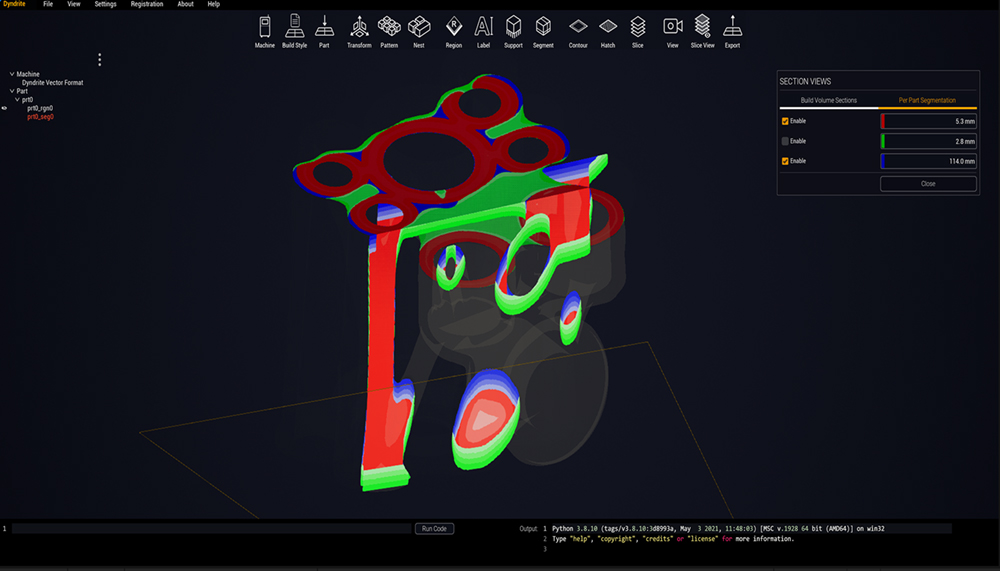

Based in 2015 and primarily based in Seattle, Dyndrite develops geometry-agnostic, multi-threaded computation engines for additive workflows. LPBF Professional offers a programmable CAD-to-print surroundings, parameter management, construct technique automation, and traceable manufacturing processes. Ursa Main has chosen it because the core of its additive technique, beginning with its Draper engine line, which is now underneath lively manufacturing utilizing the toolset.

Ursa Main designs staged combustion propulsion methods with compact, high-thrust configurations able to vector management, throttle modulation, and mission restarts. The corporate makes use of laser powder mattress fusion (LPBF) to fabricate advanced mission-critical parts. “Collaboration with Dyndrite has enabled Ursa Main to construct superior parameter methods that have been out of attain only a 12 months in the past,” mentioned Thomas Pomorski, Director of Additive Manufacturing at Ursa Main.

Steve Walton, Head of Product at Dyndrite, mentioned LPBF Professional “instantly and constantly solved the elemental parameter and toolpath challenges that plague legacy instruments,” resulting in decreased help necessities, improved floor end, and extra constant microstructures. CEO Harshil Goel added that Ursa Main is “changing legacy workflows with a programmable, automation-ready strategy to additive manufacturing.”

Dyndrite’s software program permits the standardization and reuse of course of information throughout machines and platforms, supporting scalability in manufacturing. The corporate is backed by Gradient Ventures—Google’s AI-focused funding arm—and former Autodesk CEO Carl Bass. It was named a World Financial Discussion board Know-how Pioneer in 2021.

Software program’s Increasing Position in LPBF Optimization

Earlier this 12 months, Swedish aerospace group GKN Aerospace carried out Interspectral’s AM Explorer software program at its Engine Programs Centre of Excellence in Trollhättan. Designed to watch LPBF processes, AM Explorer makes use of AI to detect print anomalies in actual time, producing reside alerts and construct stories. The system helps GKN’s Nikon SLM NXG XII 600 printers, giving engineers entry to over 400 course of variables and enabling automated defect detection and high quality management. GKN stories the device has helped cut back materials waste, enhance course of stability, and help the corporate’s push towards sustainable aerospace manufacturing.

Final 12 months, Belgian service bureau 3iD grew to become the primary adopter of AMIS Professional software program for batch preparation of HP Multi Jet Fusion 3D printers. Developed by AMIS, a subsidiary of HYBRID Software program, the device permits voxel-based nesting, slicing, and automatic half placement throughout print builds. 3iD stories a 50% enhance in nesting density and quicker batch prep occasions utilizing the platform. AMIS Professional’s means to streamline construct setup and cut back cost-per-part has been cited by each 3iD and the software program’s builders as a key think about enhancing manufacturing economics for polymer and binder jet methods.

Prepared to find who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to remain up to date with the newest information and insights.

Featured picture exhibits Dyndrite LPBF Professional. Picture through Dyndrite.