Rocket engine producer Ursa Main and Sirius Applied sciences—the U.S. subsidiary of Tokyo-based Revolutionary House Service (ISC)—have entered into a brand new settlement for the acquisition of ten Hadley small launch engines, which function parts produced utilizing 3D printing. The partnership additionally features a collaborative effort to develop a medium-lift engine primarily based on Ursa Main’s bigger Arroway mannequin, with most of its components additionally incorporating 3D printing know-how.

“The partnership ISC/Sirius and Ursa Main have cast is a really particular and highly effective collaboration between two younger, however extremely agile and revolutionary firms,” stated Ursa Main CEO Dan Jablonsky. “Our groups in Berthoud, Colorado, and our superior manufacturing heart of excellence in Youngstown, Ohio, are proud to ship our signature Hadley engines… and advance the event of medium-launch propulsion know-how.”

New U.S.-Japan House Cooperation

The collaboration follows the U.S. Division of State’s approval of a technical help settlement, permitting the export of particular technical information associated to the Hadley engine, which was bought by ISC/Sirius in March 2024. The businesses described the approval as a landmark occasion—among the many first of its form in over a era between American and Japanese house know-how corporations.

In response to ISC/Sirius, Ursa Main was chosen primarily based on its manufacturing capabilities and its skill to align with the event timeline of the ASCA reusable house automobile, which is scheduled for a check flight in the US later in 2025. In a press launch, the businesses acknowledged that the deliberate improvement of a medium-lift engine, derived from Ursa Main’s Arroway platform, will proceed by way of 2028. Throughout later phases, ISC/Sirius and Ursa Main intend to implement manufacturing enhancements to assist extra testing actions.

“This aligns with the dedication made throughout the U.S.-Japan summit in February between the 2 governments to strengthen cooperation within the industrial house sector,” the businesses acknowledged. “We actually consider that advancing concrete collaboration between personal firms like ours will deepen the U.S.-Japan relationship additional. Shifting ahead, we’ll work carefully with Ursa Main to attain our purpose of conducting a flight check of ASCA 1.0 within the U.S. later this yr.”

Ursa Main’s Propulsion Techniques: Hadley and Arroway

Ursa Main is a privately funded U.S. firm targeted solely on rocket propulsion methods, utilizing superior digital instruments and additive manufacturing to quickly produce high-performance, cost-effective engines.

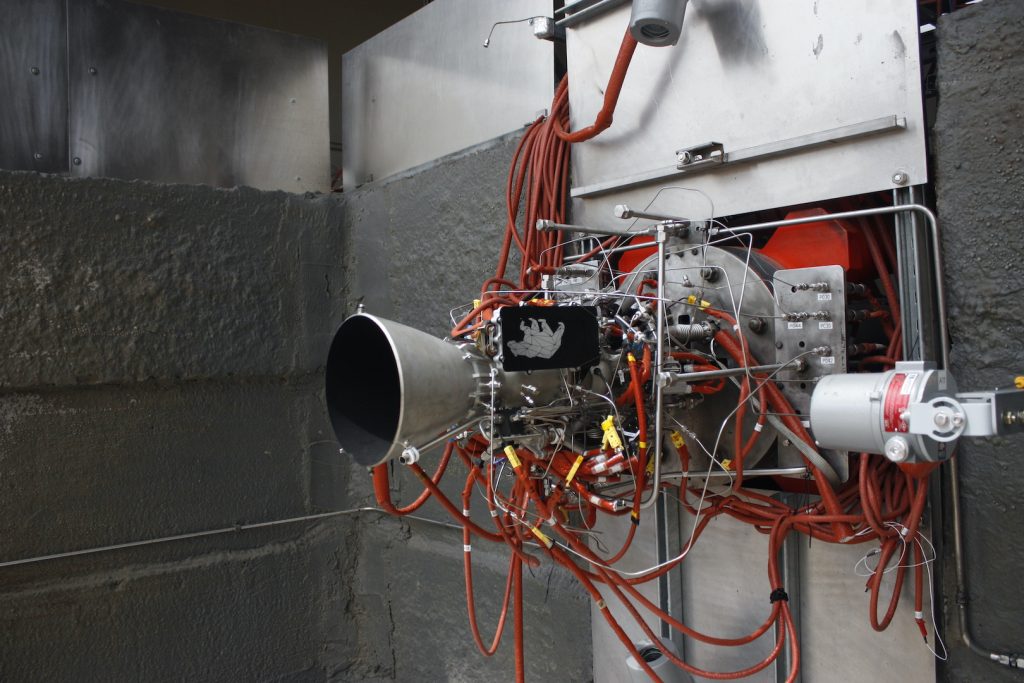

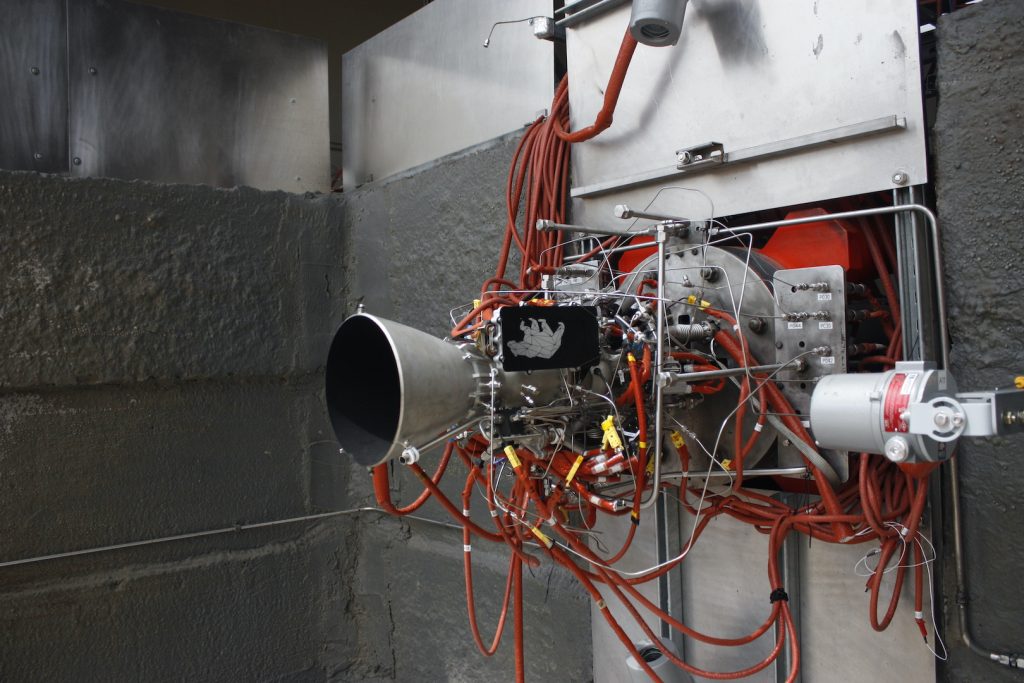

The corporate’s Hadley engine is its flagship product and the primary U.S.-built oxygen-rich staged combustion engine to endure scorching hearth testing. Designed for small launch automobiles, Hadley delivers 5,000 kilos of thrust and is engineered for versatility throughout launch, hypersonic, and orbital functions.

In the meantime, the Arroway engine represents Ursa Main’s next-generation platform for medium-lift missions. Set to be able to 200,000 kilos of thrust, the brand new system is designed so that almost all of its components may be 3D printed, enabling its fast iteration throughout improvement, and its future manufacturing to be scaled the place wanted.

Ursa Main’s Observe Report of Collaboration

In 2024, Ursa Main, in collaboration with Virginia-based Raytheon Applied sciences, efficiently accomplished missile flight testing of a long-range strong rocket motor (SRM) for the U.S. Military. The SRM was manufactured utilizing Ursa Main’s proprietary Lynx 3D printing know-how, which—mixed with Raytheon’s digital engineering experience—enabled the groups to speed up improvement timelines and scale back manufacturing prices.

In one other initiative, Ursa Main secured $12.5 million in funding from the U.S. Navy and the Workplace of Strategic Capital (OSC) to scale the manufacturing of 3D printed SRMs. By means of the prototype undertaking settlement, the corporate is designing, manufacturing, and testing a brand new SRM prototype for essential missiles. This adopted the information that the corporate is 3D printing the Navy’s Mk 104 twin rocket motor, which powers the SM-2, SM-3, and SM-6 missiles.

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

You may as well observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits Hadley propulsion system. Photograph through: Ursa Main.