Researchers at Nationwide Taiwan College have developed a synthesis technique that allows simply 100 nm of tantalum nitride to outperform a lot thicker photoanodes, paving the way in which for scalable, cost-effective photo voltaic hydrogen manufacturing.

A workforce of researchers on the Division of Chemistry, Nationwide Taiwan College, has developed a synthesis technique that considerably reduces the fabric utilization in photoelectrochemical water splitting—with out compromising efficiency. The innovation permits a mere 100 nm layer of tantalum nitride (Ta₃N₅) to outperform conventional thick-film photoanodes made with oxide-based precursors.

Ta₃N₅ is a promising semiconductor for changing daylight into hydrogen attributable to its seen gentle absorption and supreme bandgap. Nonetheless, sensible adoption has been restricted by its poor cost transport properties, sometimes requiring thick, tantalum-rich layers. Tantalum is each costly and scarce, making such approaches unsustainable for scale.

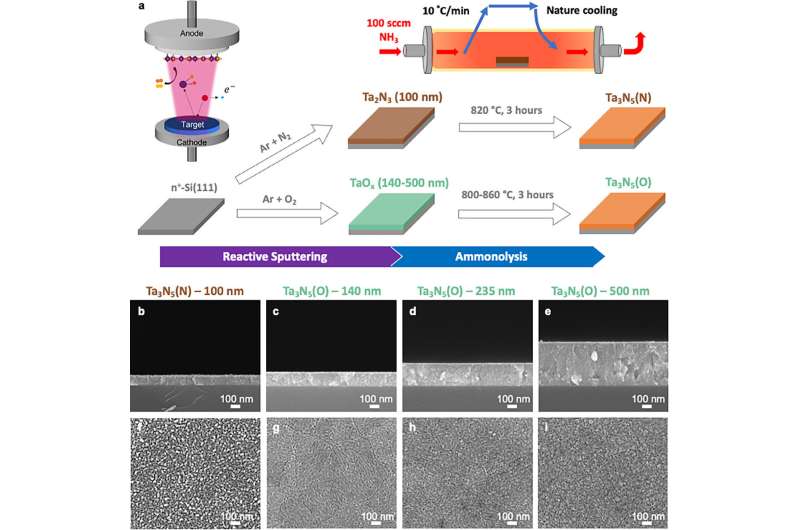

Printed in Small, the brand new technique introduces a chemically engineered precursor—bixbyite-type Ta₂N₃—to provide ultrathin, high-efficiency Ta₃N₅ photoanodes on silicon. This metastable precursor readily converts into Ta₃N₅ throughout thermal processing, forming skinny movies that show superior gentle harvesting and cost separation.

Notably, the Ta₂N₃-to-Ta₃N₅ transformation introduces hint subnitride impurities on the silicon interface—an surprising profit. These phases are extremely conductive and act as environment friendly channels for extracting photogenerated carriers, addressing a long-standing bottleneck in nitride-based vitality units.

“By engineering the Ta₂N₃ precursor and leveraging its distinctive interfacial chemistry, we achieved exceptional enhancements in photocurrent and effectivity—utilizing far much less tantalum,” mentioned lead researcher Chang-Ming Jiang.

Complete structural, optical, and electrochemical analyses confirmed that this interface-engineered method permits larger efficiency than thicker, typical Ta₃N₅ movies, whereas being extra sustainable and cost-effective. This advance not solely reduces the fabric footprint of photo voltaic hydrogen methods but in addition provides a scalable route for manufacturing next-gen photoelectrodes. The analysis highlights the potential of metastable precursor chemistry and interface design in creating environment friendly, low-cost options for light-driven vitality conversion. Because the push for clear hydrogen intensifies, improvements like this might play a pivotal position in attaining scalable, economically viable solar-to-fuel applied sciences.