It is a small compact ultrasonic sensor for business 4.0 options low energy, real-time information communication for industrial robots.

Engineers typically battle with squeezing complicated ultrasonic sensing into tiny areas like M12 housings whereas sustaining accuracy and reliability in harsh industrial environments like mud, excessive temperatures, electrical noise, or vibrations that may mess up measurements.

Additionally they want so as to add sensible options like real-time communication with the sensor, guarantee low energy use for battery-powered gadgets, and construct in protections towards energy surges or faults with out bloating prices or complexity.

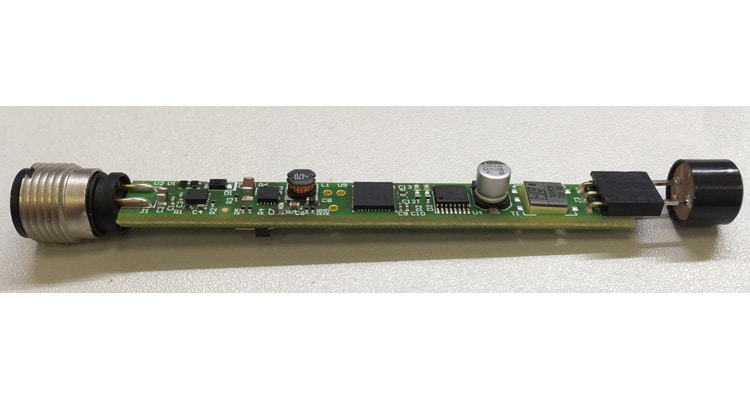

The TIDA-01386 reference design solves these by offering a ready-to-adapt blueprint for the ultrasonic sensor with compact measurement to suit inside an M12 housing with a excessive integration and an optimised structure. The design contains an Enter-Output-Hyperlink interface for communication with management programs, making it appropriate for Business 4.0 purposes.

These ultrasonics sensors can be utilized in robots that assist in logistics warehouses, industrial robots with programmable features, can be utilized as displacement transmitters, degree transmitters, and can be utilized in drones.

Key system specs embrace an Enter-Output-Hyperlink communication interface that comes with the software program to analyse the info in actual time. The vary of this sensor extends from 10 cm to 5m. It makes use of a frequency of 300KHz for brief vary of as much as 30cm, and a frequency of 58kHz for lengthy vary from 30cm to 5m.

This sensor makes use of the TIOL111 chip for the IO-link communication. It lets the sensor discuss to manufacturing unit machines utilizing IO-Hyperlink. It runs on 7-36 volts, protects towards electrical shocks or flawed wiring as much as 55 volts backward, and may face up to static surges as much as 1,000 volts. It’s environment friendly, utilizing little or no energy when idle, and sends alerts if one thing’s flawed, like overheating.

The sensor module accommodates a piezoelectric transducer that turns electrical pulses into ultrasonic sound and again once more, a centre-tap transformer that reinforces the drive voltage, and a system-on-chip that homes the analogue front-end, programmable-gain amplifier.

Analogue-to-Digital converter and Digital Sign Processing to drive the transducer and interpret echoes. A low-power microcontroller oversees timing, information processing and protocol duties, and a transient-voltage suppressor shields every thing from electrical surges.

TI has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has extra information concerning the reference design. To learn extra about this reference design, click on right here.