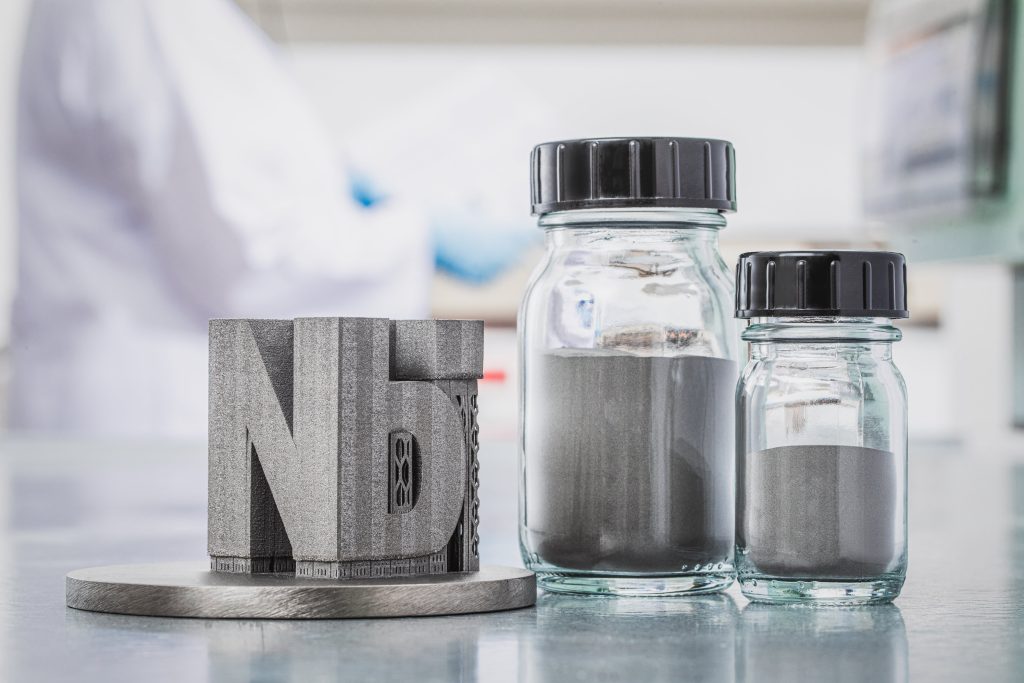

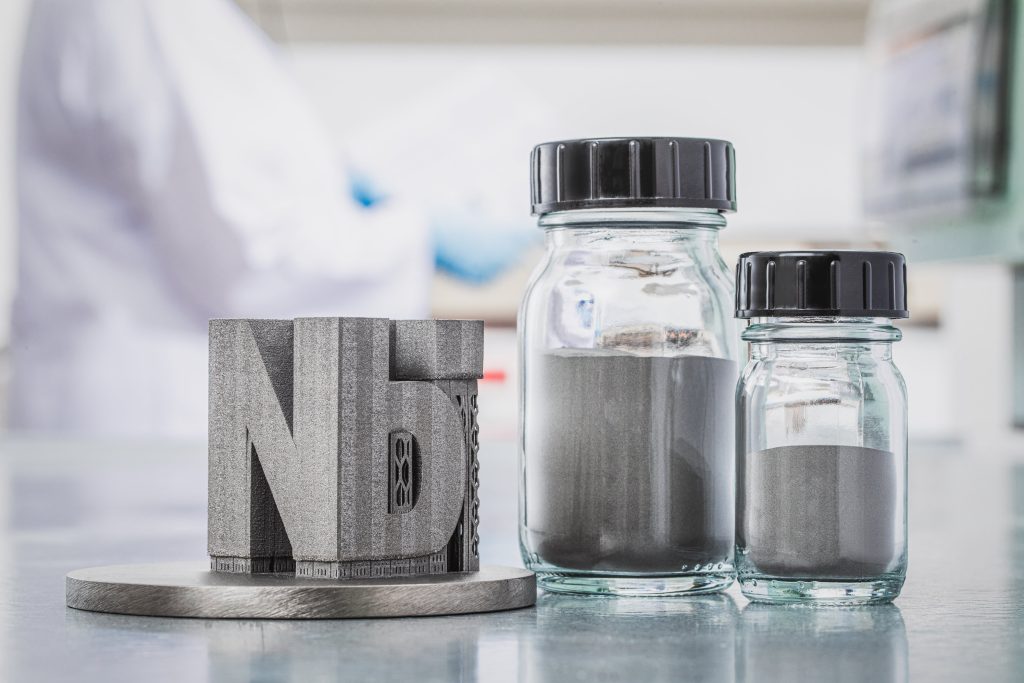

Elmet Applied sciences, a totally built-in U.S.-owned producer of tungsten and molybdenum, has signed a strategic settlement with TANIOBIS GmbH, a German firm specializing in high-purity niobium and tantalum supplies. The partnership establishes a home distribution channel for C-103 (Nb-10Hf-1Ti) and FS-85 (Nb-28Ta-10W-1Zr) powders utilized in additive manufacturing, with provisions to develop into further alloy formulations.

Free registration is open for Additive Manufacturing Benefit: Aerospace, Area, and Protection. Tickets are restricted, the longer term isn’t.

The collaboration will assist the North American aerospace and protection sectors by bettering entry to refractory steel powders essential for high-performance purposes. Elmet, which acquired H.C. Starck Options Americas in 2023, will contribute its experience in powder metallurgy and present infrastructure to fabricate and ship niobium- and tantalum-based powders. In keeping with Govt Vice President of Technique Scott Knoll, “This collaboration enhances provide chain resilience and reliability throughout essential Western, European, and North American industries.” Knoll added that the corporate goals to pursue comparable alliances aligned with long-term development and operational agility.

TANIOBIS, rebranded in 2020 following its acquisition by JX Metals and Mining Company in 2018, manufactures additive manufacturing powders together with C-103, FS-85, and Cb-752. “Elmet is the best associate to ship complete buyer and utility assist to the U.S. aerospace and protection industries,” stated Dr. Ole Brettschneider, Chief Business Officer at TANIOBIS. He emphasised the benefit of mixing niobium powder manufacturing capabilities with Elmet’s utility growth infrastructure. Each corporations share a standard heritage in H.C. Starck.

C-103 is a niobium-hafnium-titanium alloy recognized for high-temperature power, ductility, and creep resistance. These properties make it appropriate for house propulsion techniques, the place it gives efficiency advantages at a decrease weight than different refractory alloys. FS-85, a niobium-tantalum-tungsten-zirconium alloy, delivers excessive tensile power, fatigue resistance, and thermal stability, making it appropriate for structural aerospace parts working beneath excessive thermal hundreds.

Niobium is the lightest refractory steel and displays excessive ductility, biocompatibility, temperature stability, and superconductivity. These attributes contribute to its use in aerospace, nuclear, power, medical, and automotive sectors. Tantalum gives corrosion resistance, excessive power, and biocompatibility, with purposes in aerospace, chemical processing, nuclear techniques, and medical implants.

Rising Industrial Concentrate on Niobium and Tantalum Provide Chains

Croom Medical, an Eire-based contract producer, and World Superior Metals (GAM), a U.S. provider of tantalum merchandise, lately partnered to create a closed-loop provide chain for 3D printed tantalum implants. The initiative recycles unused tantalum powder and makes use of Colibrium Additive M2 laser powder mattress fusion (LPBF) system to supply medical parts with intricate geometries. This mannequin reduces waste, secures uncooked materials availability, and permits the broader use of tantalum in surgical purposes the place its biocompatibility and corrosion resistance provide clear benefits over extra generally used supplies equivalent to titanium and cobalt-chromium.

In the meantime, steel 3D printer producer Velo3D signed a five-year unique provide settlement with Australian powder producer Amaero for niobium C103, molybdenum, tantalum, tungsten, and zirconium powders. Velo3D will use Amaero’s powders in its Sapphire and Sapphire XC machines and develop proprietary print parameters for C103 and refractory alloys. These parameters shall be included in new machine licenses at no further price. Amaero has allotted capital investments of roughly A$72 million via FY2026 to develop its U.S. manufacturing footprint, together with 4 gasoline atomizers and devoted rooms for producing refractory and titanium alloy powders.

AMAA 2025 is right here. One occasion. Numerous insights. Safe your house now.

Prepared to find who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to remain up to date with the newest information and insights.

Featured picture exhibits high-purity niobium alloy powder and 3D printed part. Picture through TANIOBIS.