Steady Composites (CCI), a composite 3D printing expertise developer, has been awarded a multi-year, multi-million-dollar contract from the U.S. Air Drive to advance the event of high-performance composite supplies utilizing its proprietary Steady Fiber 3D (CF3D) expertise. The undertaking is structured in two phases, aiming to reveal CF3D’s potential for aerospace purposes.

What’s Steady Fiber 3D?

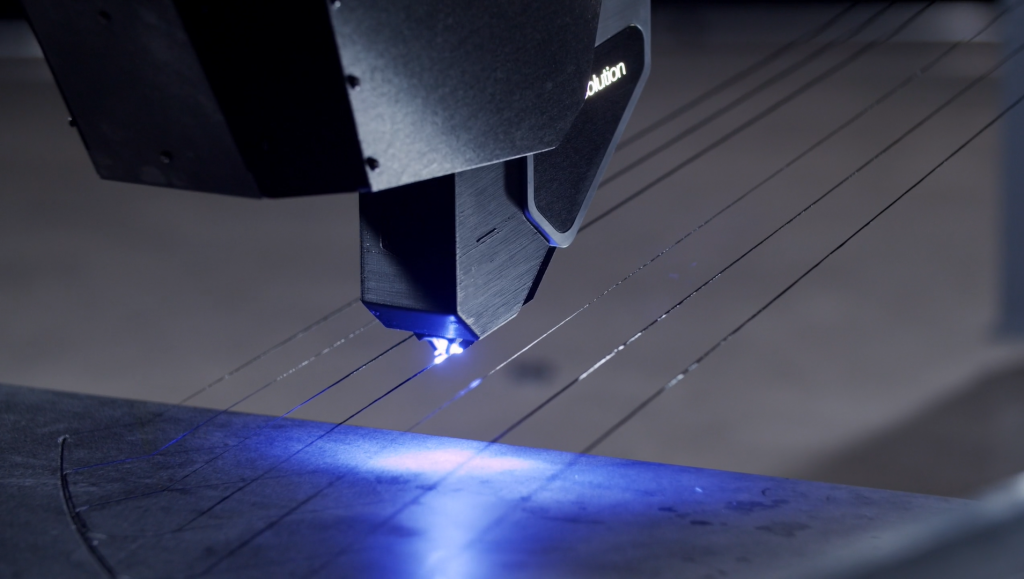

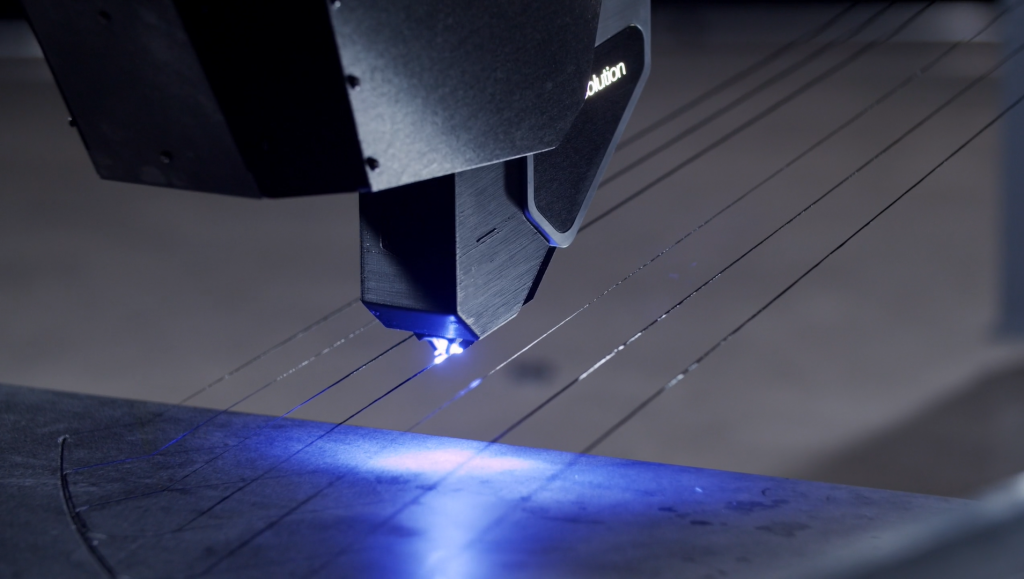

CF3D is an automatic composite manufacturing expertise that makes use of steady dry high-strength fibers impregnated on-site with a customizable, snap-curing thermoset resin. A robotic finish effector, managed by proprietary software program on a transferring or rotating platform, ensures exact fiber orientation and half geometry. This automated course of allows the manufacturing of robust, light-weight, near-net-shape parts with advanced geometries, providing larger accuracy in comparison with conventional handbook hand layup strategies.

Undertaking Overview

The primary section, at the moment underway, focuses on establishing baseline materials properties and validating the efficiency of CF3D-fabricated parts in comparison with these produced utilizing conventional strategies, equivalent to Carbon-Carbon composites.

The second section will broaden these efforts by scaling as much as full-size part manufacturing and initiating flight testing, alongside refining the CF3D manufacturing course of and exploring broader purposes in high-temperature aerospace environments.

U.S. Protection Investments in Additive Manufacturing

In associated developments, Elementum 3D, a developer of superior metallic supplies and print parameters for additive manufacturing, was chosen as an EWAAC awardee. The corporate will contribute its experience in high-performance supplies and AM processes to assist initiatives aligned with the Air Drive’s digital transformation and armament modernization objectives. The corporate is thought for its proprietary Reactive Additive Manufacturing (RAM) expertise, which allows printing of superior supplies beforehand unattainable with typical strategies.

In June, Divergent Applied sciences, an AI-driven 3D manufacturing options supplier, was additionally chosen to take part within the EWAAC program. Divergent’s Adaptive Manufacturing System (DAPS) integrates AI-driven design, high-volume additive manufacturing, and robotic meeting to speed up the event and deployment of next-generation weapons techniques.

The EWAAC initiative is a $46 billion multi-award Indefinite Supply/Indefinite Amount (IDIQ) contract geared toward accelerating innovation inside the U.S. protection sector.

What 3D printing tendencies do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals 3D printing a composite half with CF3D. Picture through Steady Composites.