Prepared-to-use semiconductor testing setups cut back calibration time and assist researchers obtain constant outcomes from prototype to manufacturing.

Testing new semiconductor gadgets like silicon carbide (SiC) and gallium nitride (GaN) typically requires sophisticated setups that take time to construct and calibrate. Engineers and researchers want correct outcomes whereas testing to design dependable merchandise.

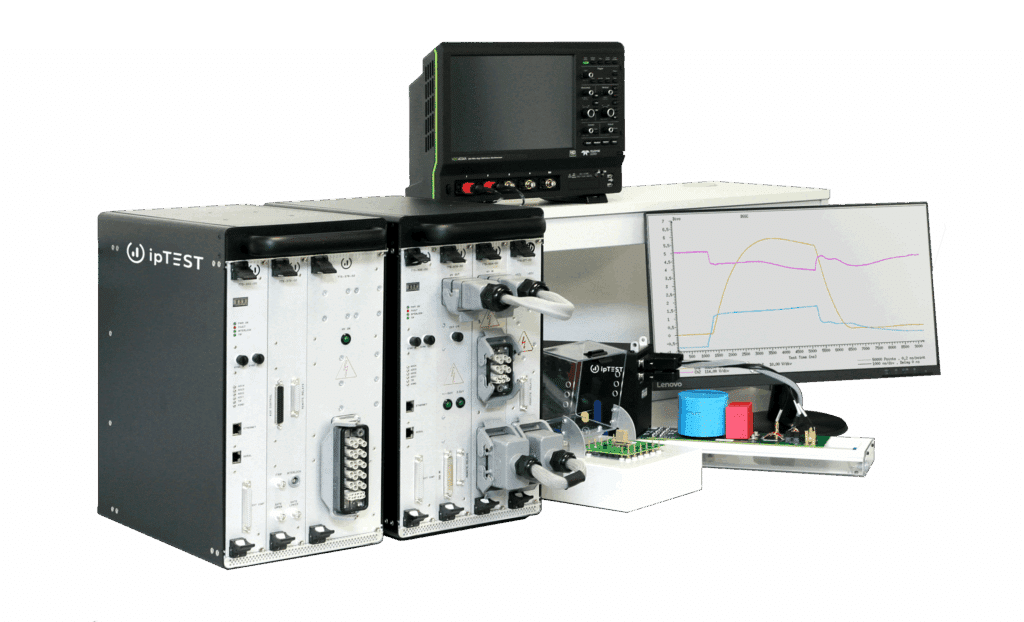

The Microtest Group launches two new testing programs: Quasar200 and Pulsar600 , these take a look at instruments remedy the issue with sophisticated setup with plug-and-play, which lets customers begin testing energy semiconductor gadgets with out constructing {custom} take a look at rigs or doing complicated wiring. This helps labs and engineers save time whereas amassing dependable, repeatable knowledge.

The Quasar200 is designed for testing normal and mid-range energy semiconductor gadgets created from silicon (Si), gallium nitride (GaN), and silicon carbide (SiC). It focuses on exact DC and AC measurements, making it appropriate for laboratory analysis, gadget characterisation, and datasheet growth.

The Pulsar600 is constructed for high-current and high-power testing, significantly for SiC-based inverters and automotive programs. It helps short-circuit and stress assessments as much as 1,000 A DC and over 10,000 A AC, serving to engineers validate the efficiency and security of next-generation energy modules utilized in electrical autos and industrial purposes.

The programs measure how semiconductor gadgets carry out underneath excessive present and voltage. Quasar200 is constructed for testing silicon, GaN, and SiC gadgets utilized in electronics and energy programs. It performs quick and correct DC and AC measurements with low interference. Pulsar600 extends this functionality to very excessive present purposes, comparable to automotive and inverter testing, dealing with as much as 1,000 amps DC and over 10,000 amps AC.

Each programs preserve detailed audit logs for monitoring knowledge accuracy. This enables researchers and corporations to match lab outcomes with factory-level manufacturing assessments when growing datasheets or qualifying new gadgets.

Security is constructed into each programs. They embrace enclosed testing areas and ipTEST’s SocketSafe safety, which isolates energy when gear is opened or faults happen. Low-inductance sockets cut back electrical noise, bettering take a look at stability.

Key options

- Plug-and-play setup: Prepared-to-use testing programs that take away the necessity for custom-built rigs or soldered connections.

- Extensive gadget help: Appropriate with silicon (Si), gallium nitride (GaN), and silicon carbide (SiC) gadgets.

- Excessive present functionality: Helps ultra-high present assessments as much as 1,000 A DC and 10,000 A+ AC, appropriate for SiC inverters and automotive programs.

- Measurement precision: ±0.1% accuracy throughout all voltage and present waveforms.