TFETs utilise quantum tunnelling to scale back energy consumption and improve switching pace, providing potential for IoT, neuromorphic, and wearable electronics.

Tunnel field-effect transistors (TFETs) are being developed as a attainable different to MOSFETs in low-power electronics. MOSFETs use warmth to maneuver electrons over a barrier, a course of referred to as thermionic emission. This technique has a bodily switching pace restrict of 60 millivolts per decade at room temperature. Working at decrease voltages results in leakage, whereas elevating the voltage will increase energy use.

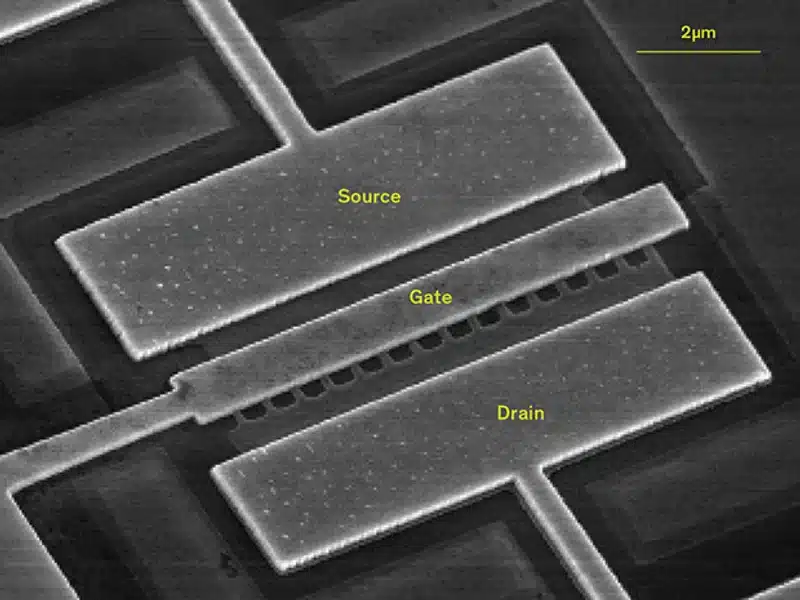

TFETs work otherwise, utilizing quantum tunnelling. The gate voltage strains up the power bands so electrons can move straight from the supply to the channel without having further warmth. This enables quicker switching at decrease voltages and reduces leakage, slicing each energetic and standby energy consumption.

These properties make TFETs enticing for functions akin to Web of Issues units, wearable know-how, and neuromorphic computing, the place low power use and lengthy battery life are important. TFETs additionally deal with short-channel results higher than MOSFETs, supporting continued chip miniaturisation.

Materials choice is vital to TFET efficiency. Compounds like indium arsenide and gallium antimonide have low band gaps and lightweight electron mass, bettering tunnelling effectivity. Two-dimensional supplies akin to molybdenum disulfide and tungsten diselenide supply robust management of the channel in compact units. Designs utilizing layered supplies like graphene and hexagonal boron nitride have additionally proven promise in delicate digital functions.

Manufacturing stays a problem. TFETs require exact band alignment, correct doping, and defect-free interfaces. Small variations throughout fabrication may cause important adjustments in efficiency. Work is underway to refine materials high quality, enhance junction management, and adapt processing strategies to current semiconductor manufacturing strains.