Titomic Restricted, an Australian firm specializing in chilly spray additive manufacturing by way of its proprietary Titomic Kinetic Fusion (TKF) course of, has signed a strategic partnership with U.S.-based superior manufacturing supplier nuForj. The settlement is meant to speed up the commercialization of TKF in North American sectors together with aerospace, protection, schooling, and industrial manufacturing.

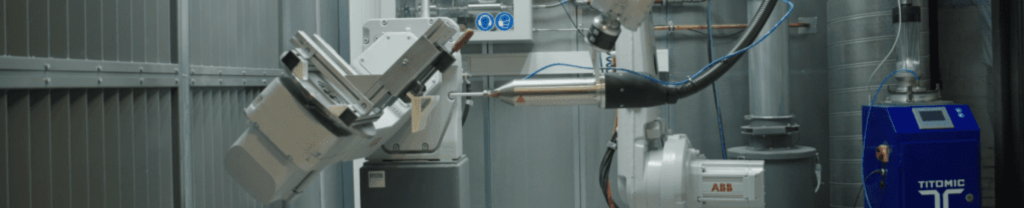

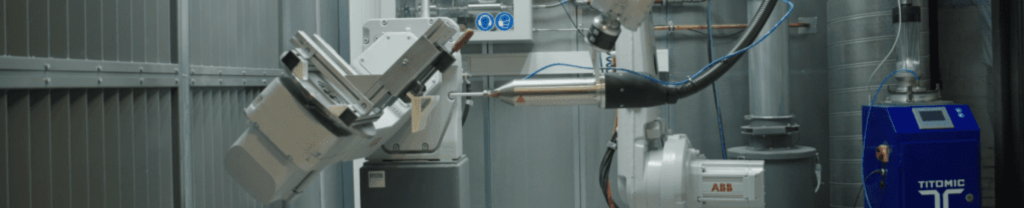

nuForj will act as a regional commercialization and expertise associate for TKF, a course of that deposits metallic powders at supersonic velocity with out melting them. This solid-state technique permits near-net-shape manufacturing, coating, and restore of metallic parts at excessive velocity and effectivity. Beneath the partnership, the businesses purpose to determine a community of additive manufacturing hubs and implement coaching applications that introduce chilly spray manufacturing strategies to engineering college students and workforce improvement initiatives.

“This partnership represents a leap ahead in our international technique,” stated Jim Simpson, CEO and Managing Director of Titomic. “Working alongside nuForj permits us to convey TKF expertise to important U.S. markets with agility and deep native perception.” Dr. Patti Dare, President of Titomic USA, famous that the collaboration “paves the best way for joint R&D initiatives and the deployment of superior manufacturing hubs throughout North America.” Rudy Vogel, Founder and CEO of nuForj, added: “We imagine Business 4.0 applied sciences and digital transformation of the manufacturing facility flooring are important to reindustrializing the U.S., powering new enterprise fashions and driving productiveness progress. Titomic Kinetic Fusion is a powerful expertise for producing high quality metallic components extremely quick and effectively, and we’re trying ahead to creating it accessible to scores of firms throughout the nation dedicated to American manufacturing.”

Titomic’s TKF course of differs from standard 3D printing in that it doesn’t require melting metallic feedstock. As a substitute, metallic powders are accelerated by way of a nozzle utilizing compressed fuel and fused upon affect, permitting for the manufacturing of corrosion-resistant and mechanically sturdy parts. This method reduces thermal distortion and permits speedy buildup of fabric on each new and current substrates. The method is especially appropriate for large-scale functions and sophisticated geometries, together with half restoration and protecting coatings in aerospace and protection techniques.

nuForj, primarily based in the USA, focuses on integrating Business 4.0 rules with digital manufacturing facility options. Its collaboration with Titomic will help the deployment of localized additive manufacturing hubs designed to cut back logistical overhead and enhance entry to chilly spray-based manufacturing companies. Along with providing contract manufacturing, nuForj can be positioned to function a coaching and schooling facilitator, serving to to construct a workforce accustomed to superior solid-state manufacturing strategies.

Strategic U.S. Investments Bolster Additive Manufacturing Ecosystem

Current developments within the U.S. additive manufacturing sector replicate a coordinated push towards reshoring industrial capability by way of long-term materials provide agreements and superior {hardware} deployment. Mmetal 3D printer producer Velo3D signed a $22 million unique provide settlement with Australia-based Amaero to supply refractory alloy powders, together with niobium and titanium variants. As a part of the deal, Velo3D will qualify Amaero’s powders to be used throughout its Sapphire printer household and combine them into machine licensing packages. Velo3D has dedicated to utilizing these supplies throughout its Speedy Manufacturing Options (RPS) companies, dedicating particular techniques to C103 and titanium alloy output.

In the meantime, SyBridge Applied sciences has expanded its partnership with Carbon, a 3D printing firm identified for its Digital Gentle Synthesis (DLS) platform. The growth consists of greater than doubling its DLS-dedicated manufacturing house at its Chicago-area facility to accommodate growing orders tied to reshoring efforts. SyBridge has produced almost two million components with Carbon’s platform, citing benefits in geometric freedom, mechanical consistency, and cost-efficient high-volume output. SyBridge CEO Byron J. Paul emphasised that the funding permits American companies to cut back provide chain publicity and set up scalable, tariff-free manufacturing capability utilizing engineering-grade supplies.

Prepared to find who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to remain up to date with the most recent information and insights.

Take the 3DPI Reader Survey — form the way forward for AM reporting in underneath 5 minutes.

Featured picture reveals Titomic Kinetic Fusion (TKF) system deployed for high-speed chilly spray additive manufacturing. Photograph by way of Titomic.