Texas A&M College, a Public Analysis Establishment, has secured $1.6 million in funding from the Protection Superior Analysis Initiatives Company (DARPA) to develop a brand new system that accelerates the evaluation of high quality and sturdiness in 3D printed components. As a part of DARPA’s SURGE program, grantees are challenged to scale back analysis instances from 18 months to only three days, whereas simplifying the method to run on a normal laptop computer. This initiative goals to facilitate wider adoption of additive manufacturing throughout the Division of Protection and is anticipated to save lots of tens of millions of {dollars}.

“That is an thrilling second for the additive manufacturing area, a group that more and more acknowledges the pressing must speed up the qualification of 3D printed components,” mentioned Dr. Mosen Taheri Andani, assistant professor of mechanical engineering at Texas A&M. “By integrating in-situ knowledge with the underlying microstructural options fashioned throughout printing, this system will bridge experience in course of monitoring, microstructure characterization, and property analysis – paving the way in which for sooner, extra dependable deployment of additive-manufactured components.”

The Problem and the Staff

Predicting the lifespan or failure level of a single 3D printed half at present requires about 18 months of in depth computation. Not like conventional manufacturing, the place analysis depends closely on machines and processes, every 3D printed half incorporates distinctive microscopic defects that affect sturdiness. These unavoidable variations make certification advanced, pricey, and time-consuming.

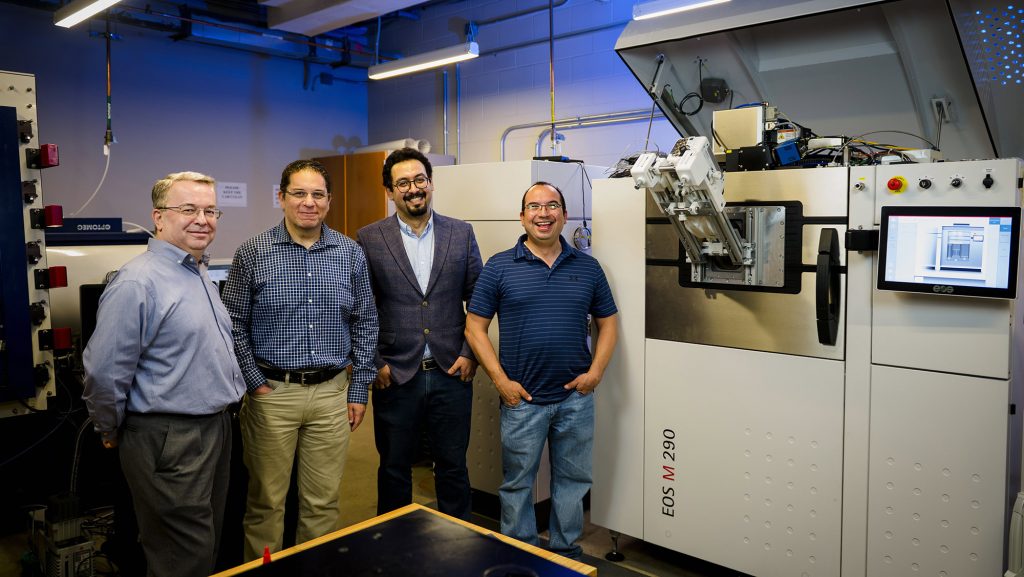

To deal with this problem, 4 researchers from Texas A&M College have determined to collaborate. The group consists of Dr. Mosen Taheri Andani, Assistant Professor of Mechanical Engineering; Dr. Raymundo Arróyave, Chevron Professor II of Supplies Science and Engineering; Dr. Aala Elwany, Professor of Industrial and Techniques Engineering; and Dr. Ibrahim Karaman, Chevron Professor and Chair of the Supplies Science and Engineering Division.

“Accelerating the certification of metallic additive manufacturing components is extraordinarily difficult. Our group is proud to contribute to this effort and assist resolve a problem important to advancing nationwide capabilities,” mentioned Dr. Taheri Andani.

This award is a component of a bigger $10.3 million, four-year collaborative grant shared with companions from the College of Michigan, Auburn College, College of California San Diego, ASTM Worldwide, and trade gamers Addiguru and AlphaStar. Funding for this analysis is managed by the Texas A&M Engineering Experiment Station (TEES).

Progressive Options: Sensors, AI, and Collaboration

In the course of the preliminary two-year part of the grant, the Texas A&M group will associate with Addiguru to develop a sensor bundle that may be built-in immediately into industrial additive manufacturing platforms. This method will monitor the printing course of in actual time by capturing knowledge from a number of sensor modalities. As soon as perfected, the group will create an AI-powered, high-resolution defect detection system able to decoding, fusing, and analyzing knowledge from numerous sensor sources.

Concurrently, Texas A&M will coordinate with the College of Michigan, AlphaSTAR, and ASTM Worldwide to speed up prediction of microstructural options generated throughout the additive manufacturing course of.

“This DARPA challenge is especially thrilling for us as a result of it represents a novel alternative to deal with one of the vital vital challenges dealing with the sector at present,” mentioned Dr. Ibrahim Karaman. “We’re assured that this work can have a transformative affect on trade and assist unlock the total potential of additive manufacturing at scale.”

3D Printing Compliance

Additive manufacturing certification is crucial to making sure half high quality, security and interoperability. In 2024, the Pennsylvania-based group’s Additive Manufacturing Heart of Excellence (AM CoE) launched the Additive Manufacturing Certification Committee (AMCC). The founding committee of 23 members, together with main firms like Ford, Johnson & Johnson (J&J), and Lockheed Martin, seeks to determine standardized audit standards for evaluating AM provide chain reliability. The committee works to develop audit requirements that align with worldwide benchmarks and confirmed trade strategies.

Elsewhere, the Utilized Science & Know-how Analysis Group of America (ASTRO America) beforehand partnered with aerospace producers Pratt & Whitney, Honeywell, and GE. This collaboration sought to simplify the onboarding course of for small 3D printing distributors. Executed by way of America Makes, it has labored to determine a standard additive manufacturing qualification template. Aerospace producers historically use distinct processors for onboarding suppliers, making certain manufacturing standards. ASTRO America goals to standardize the qualification course of, decreasing the barrier of entry for 3D printing by decreasing complexity for small companies.

Take the 3DPI Reader Survey — form the way forward for AM reporting in underneath 5 minutes.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

It’s also possible to comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals Dr. Ibrahim Karaman, Dr. Alaa Elwany, Dr. Mohsen Taheri Andani and Dr. Raymundo Arroyave. Photograph by way of Texas A&M Engineering.