Ta.Tamu, a light-weight, foldable chair developed by a partnership between 3D CAD software program supplier Dassault Systèmes and French designer Patrick Jouin, was introduced in Paris on June 25, 2025. Designed utilizing Dassault’s 3DEXPERIENCE platform, the undertaking explores how digital instruments and biomimicry can help extra sustainable design and manufacturing strategies.

“Nature makes use of solely the vitality and supplies it wants,” stated Patrick Jouin. “We wished to use this quite simple philosophy to the event of Ta.Tamu. With the assistance of latest collaborative applied sciences of Dassault Systèmes, we are actually in a position to provide you with new concepts and make them attainable, creating extra effectively whereas producing much less waste, proper from the design course of.”

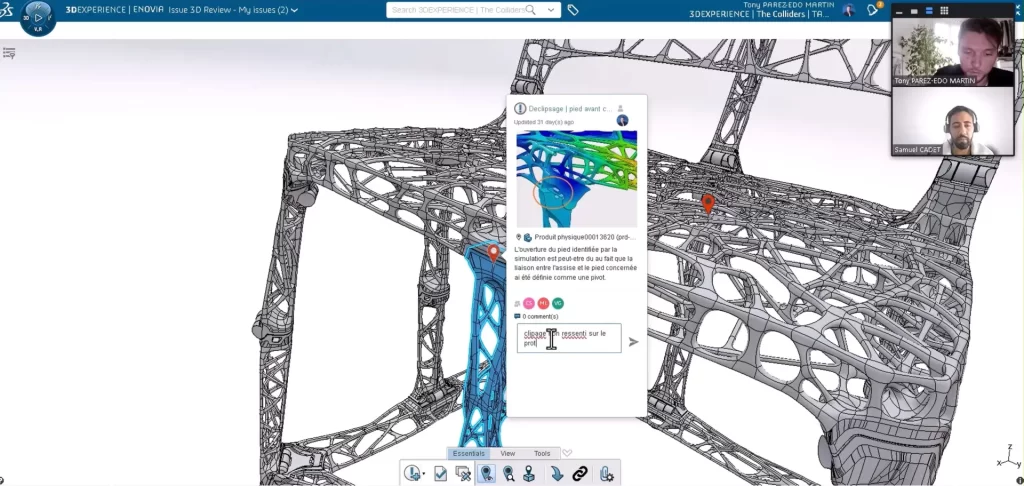

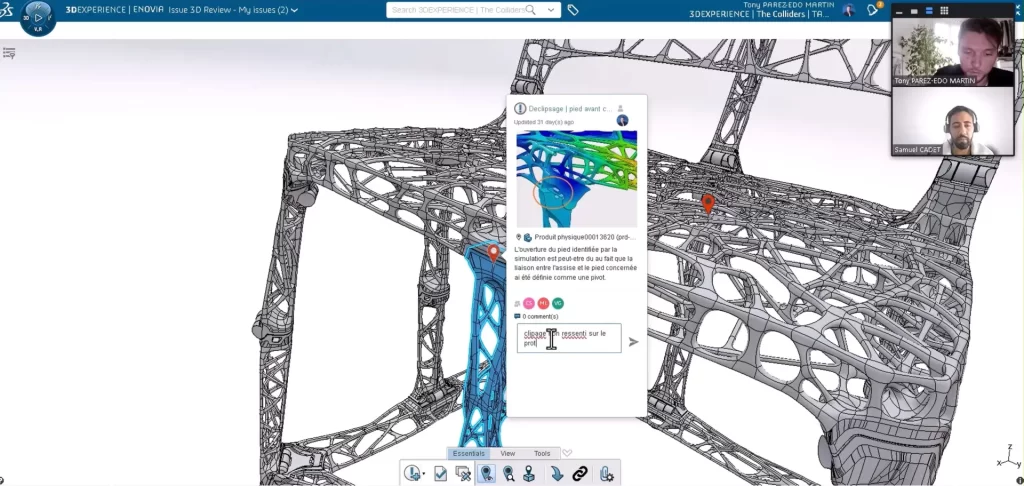

Digital Collaboration and Design Course of

Ta.Tamu was developed over 4 years by collaboration between Patrick Jouin and Dassault Systèmes’ 3DEXPERIENCE platform. The chair’s construction was impressed by biomimicry, incorporating points of human anatomy similar to bone density and joint articulation. The lattice framework weighs roughly 8.6 kilos (3.9 kg), helps as much as 220 kilos (100 kg), and could be 3D printed in a folded, flat place with out requiring meeting.

Design groups used an AI-powered digital twin to simulate the habits of assembled elements and utilized topological optimization to refine joints, articulation factors, and strain zones. The design advanced in actual time by interplay with the 3DEXPERIENCE platform, with modifications mirrored within the digital twins. The ultimate design, which featured modified geometry and improved aesthetics, weighs roughly 75% lower than it could if printed at full density.

“To enhance the world we reside in, we have now to vary the way in which we produce, design and use supplies. Ta.Tamu represents a name to motion for trade to embrace a generative financial system as an alternative of continuous to create with out limits,” stated Anne Asensio, Vice President Design Expertise, Dassault Systèmes. “Ta.Tamu was created with the expertise used to innovate sustainably in industrial contexts. As a science-based firm, we need to create worth for society in each facet of individuals’s lives by our 3DEXPERIENCE platform. Design processes integrating modeling and simulation from the beginning result in improvements that enhance actual life.”

3D Printed Furnishings

Ta.Tamu provides to an ongoing exploration of 3D printing in furnishings design, a subject that has regularly moved from experimental prototyping to extra superior purposes involving simulation, sustainability, and structural efficiency.

In 2016, U.S. furnishings producer Herman Miller started incorporating 3D printing into its design and growth workflows. Recognized for its Aeron and Eames chairs, the corporate used additive manufacturing to supply prototypes extra rapidly and iterate designs earlier than committing to manufacturing. A lot of this work came about at its services in Tub and Chippenham within the UK, later consolidated right into a 15,974-square-meter headquarters in Melksham referred to as Portal Mill. The brand new website introduced collectively analysis and growth groups beneath one roof to help a extra built-in method to product testing and refinement.

In 2018, Spanish design group Nagami collaborated with numerous architects and designers, together with Zaha Hadid Architects, for the undertaking Courageous New World: Re-thinking Design within the New Age of Expertise. Two of the ensuing items, Bow and Rise, have been designed by Patrick Schumacher and Sebastian Anda utilizing PLA bioplastic and printed through pellet-extrusion. The chairs have been influenced by “structural optimisation processes usually present in nature,” and featured complicated floor geometries and coloration gradients. In accordance with Nagami, the types aimed to reframe the spatial relationship between furnishings and its setting.

Be a part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, House, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the newest 3D printing information.

You can even comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits Ta.Tamu char. Picture through Dassault Systèmes.