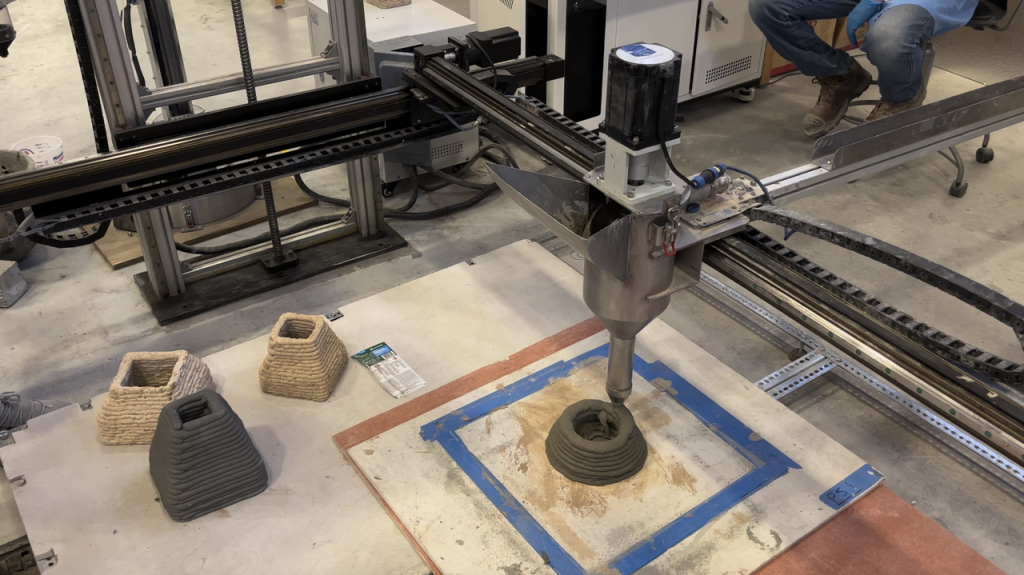

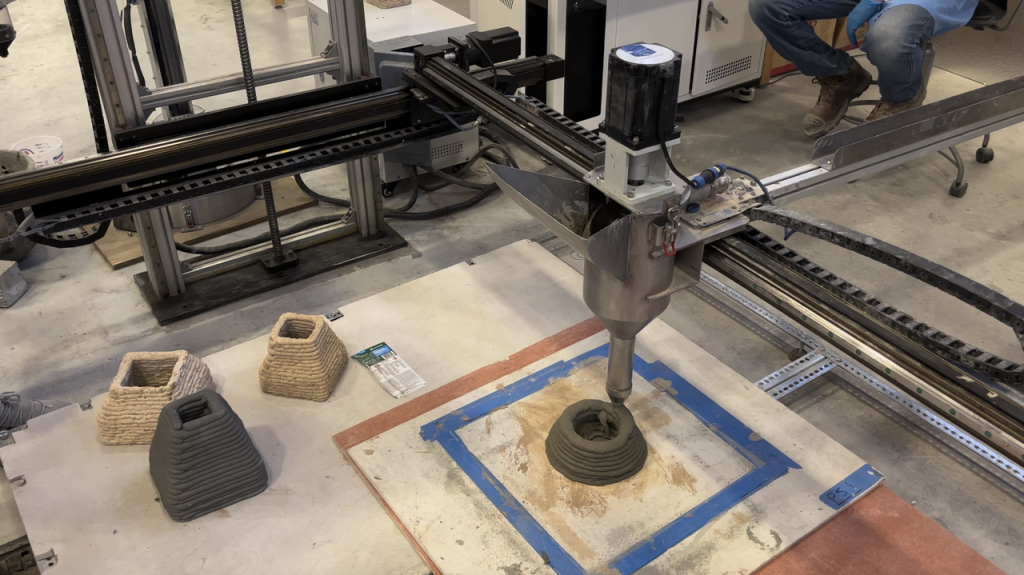

Progress Group, an organization specializing in mechanical engineering and precast concrete methods, has launched a proprietary 3D printing course of generally known as Selective Paste Intrusion (SPI). Designed for large-format concrete elements, the SPI system achieves a layer decision of three millimeters and is presently in operation on the firm’s facility in Brixen, South Tyrol.

At this 3D printing middle, Progress engineers produce each customer-specific parts and experimental prototypes. The printer’s construct quantity, measuring 4 meters by 2.5 meters by 1 meter, permits for advanced geometries and floor element sometimes troublesome to realize with standard strategies. SPI allows focused materials deposition, lowering general concrete utilization by putting paste solely the place structurally crucial.

Relatively than printing full-scale constructions on-site, Progress is making use of SPI to precast concrete manufacturing inside a managed manufacturing unit atmosphere. In response to the corporate, this strategy improves high quality assurance, avoids weather-related delays, and ensures extra constant working situations. Use instances embrace architectural façades, balcony components, advanced formwork, and specialised prefabricated items.

The SPI system was developed in-house by the corporate’s analysis and improvement group. Surfaces printed utilizing this technique exhibit notable precision, and the system’s three-millimeter decision helps detailed formwork with out counting on conventional casting molds. That is significantly related for restricted manufacturing runs, the place mould fabrication would in any other case be time- and cost-intensive.

Progress positions its additive manufacturing capabilities as a complement to traditional concrete development strategies relatively than a wholesale substitute. By specializing in geometrically advanced or low-volume purposes, the corporate goals to broaden design prospects whereas lowering materials waste and streamlining manufacturing workflows.

Increasing the Capabilities of 3D Printed Concrete

Researchers on the College of New Mexico (UNM) have developed a self-reinforced, ultra-ductile cementitious materials tailor-made for 3D printing. Addressing the brittleness of standard concrete, the group, led by assistant professor Maryam Hojati, integrated polymer fibers into the combo, enabling it to resist tensile and bending forces with out the necessity for metal reinforcement. The undertaking aimed to beat one of many key limitations in 3D printing concrete: the incompatibility of conventional rebar with extrusion-based processes.

Whereas the UNM group centered on mechanical flexibility, latest developments in materials enhancement have emphasised thermal and structural efficiency. One instance is the College of Virginia’s work on graphene-enhanced concrete, which seeks to enhance energy and sturdiness whereas lowering environmental affect. Graphene’s integration into cementitious supplies allows denser microstructures, probably reducing permeability and increasing structural life spans. Though primarily examined for forged parts, the findings help wider curiosity in high-performance concrete formulations.

AMAA 2025 is right here. One occasion. Numerous insights. Safe your house now.

Prepared to find who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to remain up to date with the most recent information and insights.

Featured photograph exhibits SPI-printed architectural façade prototype. Picture by way of Progress Group.