On this version of SLICED, the 3D Printing Business information digest, we compile the most recent developments throughout the additive manufacturing (AM) sector, together with govt modifications, navy certifications, and developments in titanium bicycle design and archaeological verification.

In at present’s digest, updates span reseller partnerships, software program releases, educational funding, and nationwide ecosystem mapping in Türkiye.

Learn on for detailed experiences from AMUG, Meltio, Hexagon, Renishaw, UltiMaker, and extra.

AMUG Pronounces New Board Members Forward of 2026 Convention

Kicking off Might’s digest, the Additive Manufacturing Customers Group (AMUG)—a U.S.‑based mostly 501(c)(6) dedicated to industrial 3D‑printing schooling—elected 4 new board members for the 2025–2026 time period in preparation for its annual convention, set for March 15–19, 2026, in Reno, Nevada. Heather Natal (GoEngineer) retains her function as Secretary, joined by Alex Roschli (Oak Ridge Nationwide Laboratory) as Director of Training & Convention, Kim Killoran (Stratasys) as Director of Advertising and marketing & Occasions, and Dallas Martin (Toyota) as Director of Sponsors & Exhibitors. AMUG President Shannon VanDeren emphasised that the board’s various skillset goals to uphold AMUG’s dedication to advancing industrial additive manufacturing functions.

The newly elected administrators will oversee AMUG’s program, sponsor relationships, and organizational operations. Roschli and Martin have been latest recipients of AMUG’s Distinguished Innovator Operator (DINO) awards, recognizing important contributions to the trade. AMUG’s broader mission consists of fostering innovation {and professional} growth inside additive manufacturing by way of technical displays, workshops, and collaborative occasions.

Resellers and Distribution Updates by ERM Fab&Check, BLT Europe, Sicnova, and Extra

Shifting on to resellers and distribution, Spanish distributor Sicnova has secured unique distribution rights for Netherlands-based producer UltiMaker 3D printers throughout the Iberian Peninsula, reinforcing its decade-long partnership with the EU-based producer. Beneath the brand new association, Sicnova will provide UltiMaker’s desktop printers, consumables and spare components to corporations and establishments in Spain and Portugal.

To bolster operational assist, Sicnova plans to develop its software engineering providers and service-centre community—significantly in Catalonia—serving to purchasers validate purposeful components and combine 3D printing into manufacturing, upkeep and product growth workflows.

Turning to the Benelux area, BLT Europe GmbH—the German department of Chinese language LPBF OEM Shiny Laser Applied sciences—has tapped Dutch service home Cheylus 3D as its agent in Belgium, Luxembourg and the Netherlands to ship BLT’s laser powder mattress fusion programs.

Cheylus 3D will leverage its native market data to assist industries reminiscent of semiconductors, oil & gasoline and machine tooling with superior steel AM options.

BLT Europe’s gross sales and advertising director, Slobodan Ilic, burdened that Cheylus 3D’s deep understanding of business AM and customer-focused service mannequin aligns with BLT’s mission to develop steel 3D printing adoption. Cheylus 3D’s founder famous that the collaboration will open doorways to new mass-market steel functions.

In the meantime, Lyon‑based mostly digital‑manufacturing provider ERM Fab&Check has develop into the official French gross sales associate of Spanish producer Meltio, positioning itself to distribute wire-laser steel 3D printers such because the M600 and Robotic Cell throughout trade verticals. The settlement permits collaboration with expertise centres, robotic integrators, tooling corporations and universities to introduce welding-wire feedstock programs as a safer, cleaner various to powder-based strategies.

“Meltio’s DED expertise combines new capabilities in steel fabrication with distinctive ease of use, permitting half manufacturing, restore and multi-material cladding on CNC machines and robotic arms at minimal value,” stated Boris Hromadka, Enterprise Unit Supervisor at ERM Fab&Check. Francisco González, Meltio’s Head of EMEA, added that ERM’s experience will assist French producers deal with autonomy and supply-chain resilience.

Elsewhere in Asia, Stuttgart‑space begin‑up One Click on Steel, a subsidiary of INDEX Werke, has teamed with Seoul‑based mostly reseller FusionTechnology to introduce its cartridge-based steel 3D printers to South Korean universities and analysis centres. FusionTechnology will deal with distribution, set up and technical coaching, drawing on its experience throughout SLA, SLS and SLM applied sciences.

“FusionTechnology’s established relationships with educational establishments and deep 3D printing know-how make them the perfect associate to deliver our accessible steel AM programs to Korea,” stated Martin Heller, International Gross sales Supervisor at One Click on Steel. The partnership goals to speed up materials growth and technical coaching initiatives all through 2025.

Lastly, Portuguese AM integrator PrimeOut has been named Meltio’s official gross sales associate in Portugal, constructing on Sicnova’s wider Iberian community to develop a neighborhood ecosystem for wire-laser deposition expertise. PrimeOut will work with expertise centres, machine instrument corporations, robotic integrators and industrial customers to deploy Meltio’s programs throughout important sectors.

Meltio’s head of EMEA, Francisco González, defined that PrimeOut’s market perception and technical capabilities will assist Portuguese producers in automotive, aerospace, defence, mining, oil & gasoline and past to undertake cost-effective steel AM options, advancing regional manufacturing autonomy.

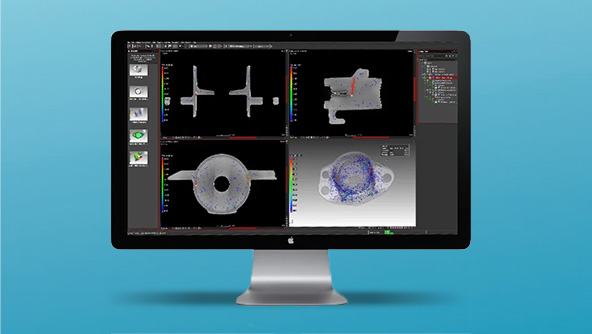

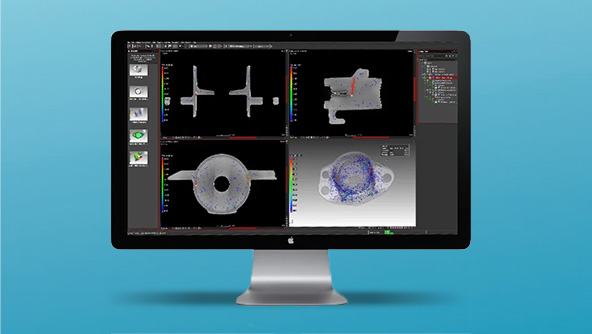

Software program Updates from Hexagon and Dyndrite

Shifting on to software program, Swedish group Hexagon AB has folded its Quantity Graphics CT‑evaluation suite totally into the Hexagon model and launched model 2025.1. A brand new module, VGTRAINER, lets engineers with out information‑science expertise label CT datasets and auto‑generate inspection fashions; French lab ELEMCA experiences that porosity checks now drop from one hour to 10 minutes.

Hexagon Manufacturing Intelligence GM Dr Daniela Handl stated tighter hyperlinks between CT, optical and tactile information will streamline non‑damaging testing workflows. Extra options embrace beam‑hardening correction and object‑particular views, positioning the platform for multi‑supply high quality pipelines.

In the meantime, Seattle-based Dyndrite, a Seattle-based developer of GPU-accelerated additive manufacturing functions, has built-in its LPBF Professional software program into the total line of steel 3D printers from Nikon SLM Options, a German producer identified for its multi-laser, high-throughput programs. Validation exams carried out with Nikon’s engineering groups confirmed the software program’s capacity to automate assist placement and apply a number of parameter units inside a single construct throughout programs together with the SLM®280, SLM®500, SLM®800, and NXG XII 600.

An illustration workshop can be held Might 13 at Nikon AM Synergy in Lengthy Seashore, California. “With Dyndrite LPBF Professional built-in into our resolution stack, we’re making high-performance steel additive manufacturing much more accessible, automated, and prepared for industrial-scale deployment,” stated Charlie Grace, Chief Industrial Officer at Nikon SLM Options. Dyndrite CEO Harshil Goel added that the collaboration permits new efficiency ranges, with LPBF Professional now out there to all Nikon SLM prospects and companions.

Allan and Nesta Ferguson Scholarships and ASTRO America Problem

In scholarship information, the Allan and Nesta Ferguson Charitable Belief introduced full scholarships for worldwide postgraduate college students in engineering and digital design on the College, protecting tuition (£22,000) and dwelling bills (£11,250). Eligible candidates have to be from particular creating nations together with Bangladesh, Egypt, India, and Nigeria, and can enroll in MSc Robotics, Engineering Venture Administration, or Digital Design applications beginning September 2025.

Scholarship functions shut Might 31, 2025, adopted by a two-stage choice involving an software overview and interviews. Award recipients should affirm acceptance inside seven days. Situations embrace strict compliance with college rules and a ban on receiving extra monetary assist from different sources through the scholarship interval.

In different information, the Utilized Science and Know-how Analysis Group of America (ASTRO America), a nonprofit centered on advancing U.S. manufacturing innovation, has partnered with international requirements physique ASTM Worldwide and Florida State College’s InSPIRE program to launch the Actionable In-Situ Consciousness Problem. The competitors seeks sensor applied sciences able to delivering real-time course of information throughout laser powder mattress fusion (LPBF) steel 3D printing. Proposals are due by Might 9, and as much as 5 groups will set up their mature, commercially viable programs at Maritech Machine in Panama Metropolis, Florida, for a three-month demonstration starting in June.

Organizers will present digital and on-site integration assist, together with fixture design and data-collection help, earlier than internet hosting a showcase on August 26–27 that includes closed-door displays and an open poster session. Judging will assess technical efficiency, information repeatability, and business readiness, with finalists advancing to stakeholder discussions and potential investor engagement.

South Korea Certifies Meltio Steel 3D Printing for Army Use

Shifting on to protection, the Republic of Korea Military licensed Meltio’s steel additive manufacturing expertise, adopting it for navy spare components manufacturing and tools repairs, notably throughout the Marine Corps Logistics Group. In keeping with Lieutenant Colonel Kim Seong-nam, commander of the upkeep battalion, the cell robot-based 3D printer considerably reduces prices and upkeep delays, enhancing logistical autonomy.

Meltio partnered with Korean agency AM Options to deploy its wire-laser deposition expertise. Adam Hourigan, Meltio’s Gross sales Supervisor for APAC, acknowledged that the certification confirms the corporate’s strategic significance in international protection sectors, beforehand validated by related deployments within the U.S. Navy and European armed forces.

Türkiye Publishes Complete Additive Manufacturing Ecosystem Information

In the meantime on the analysis nook, the non‑revenue Turkish Additive Manufacturing Affiliation (TAMA) launched the “Additive Manufacturing Panorama in Türkiye” booklet, a complete mapping of nationwide capabilities throughout sectors reminiscent of aerospace, automotive, and medical. Organized into eight thematic classes, the information lists detailed contributions from Turkish corporations, universities, and analysis establishments concerned in additive manufacturing.

TAMA will replace the information yearly, reflecting dynamic sector progress. The initiative goals to boost transparency and collaboration inside Türkiye’s industrial base, positioning the nation prominently throughout the international additive manufacturing neighborhood by selling knowledgeable funding and partnership alternatives.

Renishaw and J.Laverack Develop Titanium-Carbon Highway Bike Utilizing 3D Printing

On the functions entrance, UK metrology agency Renishaw joined bespoke body maker J.Laverack Bicycles to develop the Aston Martin .1R, a bespoke street bike combining carbon fiber with 3D printed titanium elements. Utilizing Renishaw’s RenAM 500Q system, components just like the headtube and fork dropouts have been optimized for weight and stiffness, decreasing the bike’s complete weight to only 7.5 kilograms.

David Clow, Co-Founding father of J.Laverack, defined the bespoke manufacturing as a response to calls for from Aston Martin’s design workforce, necessitating extremely custom-made frames with out conventional manufacturing limitations. Renishaw’s additive manufacturing enabled geometrically complicated titanium elements tailor-made exactly to every rider, eliminating conventional tooling constraints.

Made Smarter Launches £1M Fund to Enhance Digital Manufacturing within the UK

Shifting to funding information, UK digital adoption initiative Made Smarter unveiled a brand new £1 million fund for SMEs in North West England, providing match-funded grants of as much as £20,000 to implement superior applied sciences together with automation, AI, and 3D printing. Donna Edwards, Programme Director, famous the fund goals to extend productiveness and sustainability amongst producers navigating speedy technological change.

Foams 4 Sports activities, a earlier beneficiary, utilized its grant to automate handbook foam slicing processes, doubling productiveness and decreasing waste. Common Supervisor Ben Michael highlighted Made Smarter’s sensible assist in enabling SMEs to stay aggressive by integrating digital options into their manufacturing workflows.

Discovery Channel Makes use of Artec 3D Scanning to Confirm Alexander the Nice’s Tomb

Rounding out with 3D scanning information, Discovery Channel’s documentary sequence Expedition Unknown has utilized Artec Leo handheld 3D scanning expertise to digitally confirm a sarcophagus believed to belong to Alexander the Nice. Archaeologists scanned the artifact on the British Museum, confirming Macedonian inscriptions and particulars according to historic royal armor.

Digital archaeologist Pietro Meloni emphasised Artec Leo’s pace and wi-fi capabilities as important for delicate archaeological functions. Museum specialists used augmented actuality projections of the scan to verify stylistic and dimensional accuracy, marking a major step ahead in non-invasive archaeological validation strategies.

Prepared to find who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to remain up to date with the most recent information and insights.

Featured picture showcase archaeologist Pietro Meloni utilizing Artec Leo 3D Scanner. Picture through Discovery Channel.