Singapore has launched a nationwide normal designed to deliver additive manufacturing extra firmly into the nation’s aerospace sector.

Named “Additive Manufacturing for Aerospace – Filament Layer Manufacturing Course of Specs,” SS 708 units out course of specs for filament layer manufacturing (FLM), a sort of 3D printing that builds elements by depositing melted thermoplastic supplies one layer at a time.

Launched on the inter airport Southeast Asia commerce occasion earlier this 12 months, the usual was developed by the Singapore Manufacturing Federation’s Requirements Improvement Organisation (SMF-SDO) and Enterprise Singapore, working by means of the Singapore Requirements Council. It additionally attracts on the experience of the Civil Aviation Authority of Singapore, the Nationwide Additive Manufacturing Innovation Cluster (NAMIC), the Affiliation of Aerospace Industries Singapore (AAIS), and ST Engineering.

Aimed toward serving to native producers meet worldwide necessities, the transfer additionally helps Singapore’s broader efforts to strengthen its place as a Upkeep, Restore and Overhaul (MRO) hub within the Asia Pacific.

Ms. Choy Sauw Kook, Director-Common (High quality & Excellence), Enterprise Singapore mentioned, “Belief and security are of utmost significance within the aerospace sector, and native producers should exhibit their means to reliably and effectively produce aerospace grade parts.”

Framework targets licensed FLM manufacturing

With SS 708, Singapore gives a unified framework to information the manufacturing of comparable parts domestically. The usual contains specs for materials choice, {hardware} validation, qc, and workflow administration.

Collectively, these components are meant to assist producers obtain consistency in printing, cut back post-processing time, and make sure that elements are appropriate to be used in industrial aerospace environments.

The brand new tips additionally align with worldwide benchmarks comparable to these established by ASTM Worldwide and Worldwide Group for Standardization (ISO). That compatibility is predicted to make it simpler for Singapore-based corporations to serve international shoppers whereas retaining tempo with evolving certification necessities.

SS 708 is the primary in a sequence of deliberate efforts to formalize requirements for additive manufacturing in aerospace. Future updates are anticipated to cowl extra applied sciences comparable to vat photopolymerization, powder mattress fusion (PBF), and materials jetting.

“At SMF, we’re proud to help this milestone initiative, which not solely strengthens business capabilities but in addition paves the way in which for better collaboration and development throughout the aerospace ecosystem,” added Mr. Dennis Mark, CEO at SMF.

In parallel, educational establishments and business teams are getting ready to supply coaching and help to assist native firms undertake and apply the brand new framework. These efforts embody grants, hands-on programs, and technical steering designed to make sure that companies of all sizes can construct the required capabilities.

Additionally identified extra broadly as fused deposition modeling (FDM) or fused filament fabrication (FFF), FLM is already in use throughout the aviation business.

Within the UK, Airframe Designs used Stratasys Fortus 450mc FDM 3D printers to ship end-use parts below the Nationwide Aerospace Expertise Exploitation Programme (NATEP). The corporate has utilized the expertise to buyer tasks that require excessive repeatability, quick turnaround, and supplies licensed for aerospace use.

In the meantime, aviation provider AM Craft produced tons of of 3D printed blanking panels for Finnair’s Airbus A320 fleet. These elements, created utilizing flame-retardant ULTEM 9085 materials, are put in instantly into passenger service items and delivered on a just-in-time foundation to keep away from extra stock.

International momentum behind 3D printing requirements for aerospace

The event of requirements is turning into a cornerstone in efforts to include AM into established aerospace manufacturing workflows.

In keeping with this, SAE Worldwide issued 4 novel requirements to help the certification of metallic elements produced by way of laser powder mattress fusion (LPBF) for aerospace and area purposes. Endorsed by the Federal Aviation Administration (FAA), the requirements are designed to protect materials property knowledge integrity and allow traceability within the aerospace provide chain.

AMS7000 and AMS7001 cowl corrosion- and heat-resistant nickel alloys, AMS7002 outlines necessities for producing aerospace-grade metallic powders, and AMS7003 specifies course of controls for repeatable LPBF half manufacturing. Developed with enter from over 350 international stakeholders, the requirements acquired contribution from engine OEMs, materials suppliers, operators, tools/system suppliers.

On one other be aware, 3D printing service bureau Materialise secured EN 9100 certification for its metallic 3D printing operations, assembly aerospace-grade necessities for traceability, course of management, and regulatory compliance. This builds on its earlier certification for polymer 3D printing, which has supported the manufacturing of over 500,000 flight-ready elements at present in service.

With the addition of licensed metallic capabilities, Materialise can now tackle extra advanced parts that demand better structural power and sturdiness. Backed by European Union Aviation Security Company’s (EASA) Manufacturing Group Approval (POA) and Airbus AIPI certification, the corporate is well-positioned inside aviation provide chains. Its on-demand, small-batch manufacturing mannequin helps cut back stock dangers, reduce prices, and enhance sourcing reliability.

ake the 3DPI Reader Survey — form the way forward for AM reporting in below 5 minutes.

What 3D printing developments do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

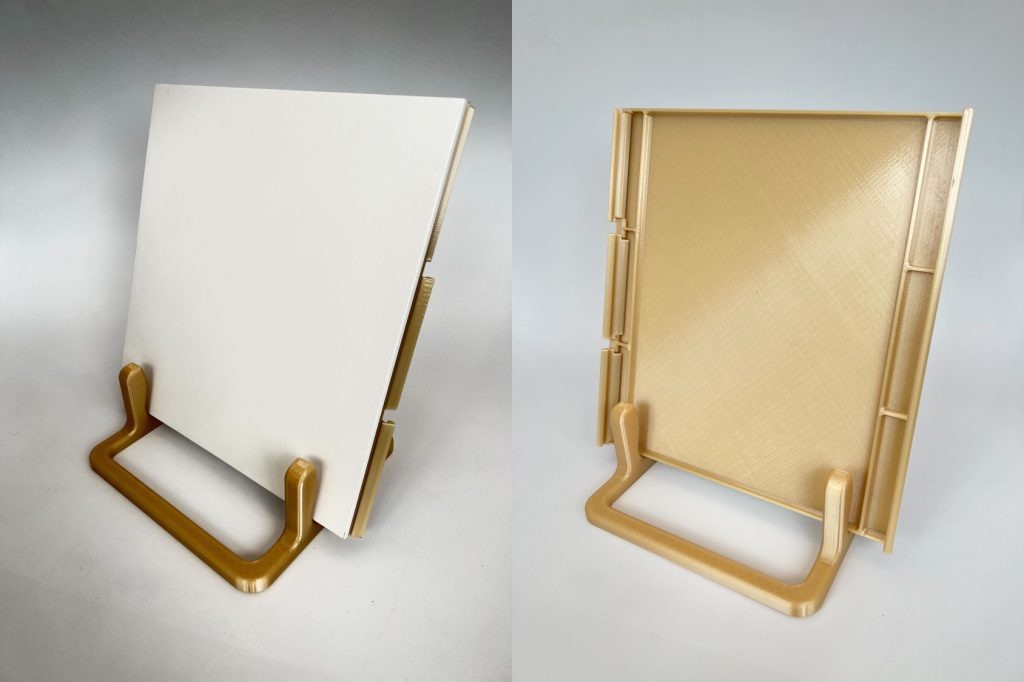

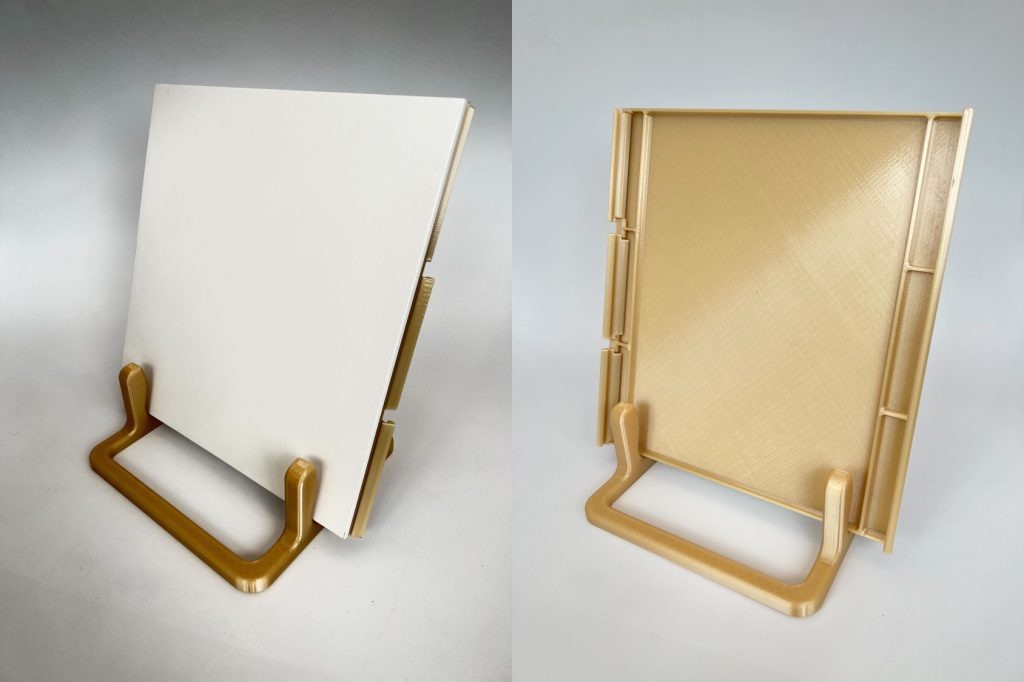

Featured picture exhibits the launch occasion for SS 708. Picture by way of AAIS.