New York-based expertise firm WAZER just lately launched its WAZER Professional waterjet cutter. This new providing follows the success of the corporate’s WAZER Desktop mannequin, which debuted in 2018 after elevating $1.3 million on Kickstarter.

WAZER Professional is a compact system optimized for engineers and producers requiring high-quality, environment friendly efficiency. It cuts by thicker supplies and operates two to 4 occasions sooner than its predecessor, considerably boosting efficiency.

WAZER’s newest system encompasses a new automated abrasive assortment system, making upkeep simpler and extra environment friendly. This allows as much as 90 minutes of uninterrupted reducing, in comparison with the WAZER Desktop’s 60-minute steady runtime. Furthermore, the brand new WAZER Professional prioritizes accessibility. Its intuitive person interface and easy-to-use WAM software program simplify operation, whereas hassle-free upkeep and responsive buyer assist take away widespread obstacles.

Beginning at simply $18,999, WAZER Professional stands out as an reasonably priced possibility within the industrial waterjet market, the place machines typically exceed $100,000. Clients may commerce of their outdated WAZER Desktop for a reduced value.

This lowers the barrier to entry, making high-quality waterjet reducing extra accessible to a wider vary of customers. In keeping with the corporate, WAZER Professional delivers probably the most highly effective reducing efficiency in its value vary, whereas requiring much less upkeep than every other system available on the market.

3D Printing Trade’s engineering group visited Stable Print 3D, a Coventry-based WAZER reseller, to place these claims to the check.

Why select the WAZER Professional?

The WAZER Professional could also be compact, measuring simply 856 x 648 x 1400 mm, however it packs a punch. Designed to suit comfortably in most workspaces, the machine encompasses a high-performance waterjet nozzle with a 0.51mm orifice. This slim aperture concentrates water stress, boosting reducing effectivity.

Because the high-speed jet exits the nozzle, it generates unfavourable stress, drawing abrasive materials by a lateral feed tube. The abrasive mixes completely with the water inside a 1.1 mm diameter mixing tube earlier than being expelled to reinforce the reducing energy.

The result’s a flexible, high-power system able to slicing by a broad vary of supplies and thicknesses. This consists of as much as 10 mm of metal and 25.4 mm of composites, glass, tile, plastic, rubber, and foam.

With a 12-by-18-inch reducing space and a kerf width of simply 0.044 inches, the WAZER Professional accommodates a variety of business, prototyping, and manufacturing duties. The gantry strikes at as much as 1,500 mm per minute (59 inches per minute), boosting throughput to satisfy tight manufacturing schedules..

Moreover, the WAZER Professional incorporates an upgraded pump that’s considerably extra highly effective than its predecessor. It delivers a hydraulic energy output of two,088 W and achieves an working stress of seven,400 psi (510 bar), enabling sooner reducing.

Reducing speeds differ by materials and thickness. For metals, WAZER Professional achieves as much as 8.4 inches per minute (ipm) in instrument metal and eight.6 ipm in stainless and gentle metal. Copper yields to the jet at 8.9 ipm, whereas titanium cuts cleanly at 8.7 ipm. Brass reaches 12.9 ipm, and aluminum slices at as much as 16.2 ipm.

For much less demanding supplies, speeds climb even larger. As much as 40.5 ipm for tile, and as a lot as 59.1 ipm for glass, plastic, and composite. A full listing of WAZER Professional materials specs is offered on the official WAZER web site.

The WAZER Professional’s gantry, nozzle, and pump. Photographs by 3D Printing Trade.

Uptime is additional elevated with a redesigned abrasive assortment system. In contrast to the Desktop mannequin, which requires customers to take away the mattress, drain the tank, and manually scoop out used abrasive, the brand new system automates the method.

Abrasive is gathered into detachable catch buckets for fast disposal, streamlining upkeep. The WAZER Professional additionally introduces a brand new handheld water hose, permitting customers to shortly rinse particles from elements after reducing.

One other new characteristic within the WAZER Professional is the backflow sensor. This detects if water enters the abrasion tube, routinely pausing waterjet operations to stop injury to the dry abrasive system. This reduces downtime, permitting points to be shortly recognized and amended.

For small-scale producers, noise from industrial gear is usually a vital concern. The WAZER Professional addresses this with a sound stress stage of simply 77.6 dB. Noise could be additional decreased with its submerged reducing characteristic, which floods the tank above the nozzle compressor tube. The water acts as a pure dampener, noticeably softening the sound.

Submersion additionally improves minimize high quality by containing the abrasive stream and decreasing warmth buildup. That is significantly helpful when working with delicate supplies resembling glass or skinny metals.

To additional bolster minimize high quality, the WAZER Professional incorporates an absolute finding jig. This precision-engineered fixture ensures constant, repeatable placement of fabric on the reducing platform.

The WAZER Professional’s detachable catch buckets, hose, and absolute finding jig. Photographs by 3D Printing Trade.

Skilled water jet reducing made straightforward

In testing, the WAZER Professional proved simple to function, making it ideally suited for newcomers searching for professional-grade waterjet capabilities. Setup is swift. Unboxing takes simply half-hour, aided by a transparent and complete guide.

Operation is managed by way of a small however efficient LCD display. The person interface permits fast file choice, Z-offset adjustment between nozzle and materials, and monitoring of abrasive ranges and waste tanks. A distinguished pink cease button provides an additional layer of security, permitting customers to halt jetting instantly within the occasion of an emergency.

Upkeep is usually a daunting impediment that limits the adoption of business manufacturing gear, like waterjet cutters. Fortunately, the WAZER Professional is designed for ease of maintenance. Its streamlined design permits customers to interchange key, consumable parts with minimal downtime. The nozzle, for example, lasts round 300 hours earlier than needing to get replaced, whereas the reducing mattress endures between 20 and 40 hours.

Routine upkeep on the WAZER Professional is refreshingly easy. The detachable abrasive catch buckets ought to be checked and emptied roughly each two hours, a fast activity that stops build-up and put on.

A number of automated options additional cut back upkeep calls for. Nozzle purging blasts high-pressure water by the nozzle to clear contaminants, whereas automated tank cleansing dislodges spent abrasive and channels it into the gathering hoppers.

Ought to issues come up, WAZER presents responsive buyer assist. The corporate companions with regional resellers, resembling Stable Print 3D within the UK, to help with setup and set up. Its in-house after-sales group additionally supplies immediate and efficient troubleshooting steering. In our expertise, WAZER’s buyer assist was useful and environment friendly, enabling our engineering group to resolve points shortly and resume testing with minimal disruption.

Testing WAZER’s WAM software program

The WAZER Professional operates by way of the corporate’s proprietary WAM software program, accessible by an internet browser and reliant on a secure Wi-Fi connection. Its clear, intuitive interface supplies swift entry to important settings and instruments.

In step one of the reducing workflow, customers import their .svg or .dxf file, which outlines the design to be minimize. Subsequent, the vector file could be scaled and positioned. The software program doesn’t permit the design file to be manually dragged. As an alternative, customers should enter numerical values.

This workflow leaves room for enchancment. Better flexibility in positioning and an expanded suite of superior instruments would improve usability. A built-in vector editor, for instance, would get rid of the necessity to alternate between WAM and third-party CAD software program.

After scaling and positioning their design, customers select the fabric from a built-in menu that includes pre-tested profiles with optimized reducing parameters. This eliminates guide calibration, streamlining the method and sparing customers the trial and error typically concerned in parameter setup.

Following this, customers outline the reducing path. This important step dictates how intently the instrument follows the design vector. WAM software program permits tabs to be added manually or routinely. These small, intentional connections anchor the half to the encircling materials, stopping it from dislodging.

Customers can select between three minimize high quality ranges within the WAM software program: Coarse, Medium, or High-quality. These choices influence the gantry’s reducing pace and, consequently, the general reducing time. The Coarse setting prioritizes pace, rising gantry motion for sooner cuts. Whereas, the High-quality setting slows the method to ship a smoother, extra refined end.

WAZER’s WAM software program scale and place, materials choice, reducing path, and tabs and leads choice interface. Photos by 3D Printing Trade.

Benchmarking the Wazer Professional

In keeping with WAZER, the WAZER Professional retains excessive precision, accuracy, and repeatability. We investigated these claims by a sequence of benchmarking exams.

We started with the check file offered by the corporate. This straightforward minimize, carried out with Ceramic in High-quality minimize mode, was profitable. The outcome shortly produced all geometries with easy edges, representing a powerful begin for the WAZER Professional.

WAZER Professional check mannequin outcomes. Photographs by 3D Printing Trade.

For batch manufacturing and industrial engineering functions, dimensional precision is vital. Good dimensional accuracy interprets to sturdy repeatability, making certain dimensions don’t fluctuate between waterjet reducing jobs.

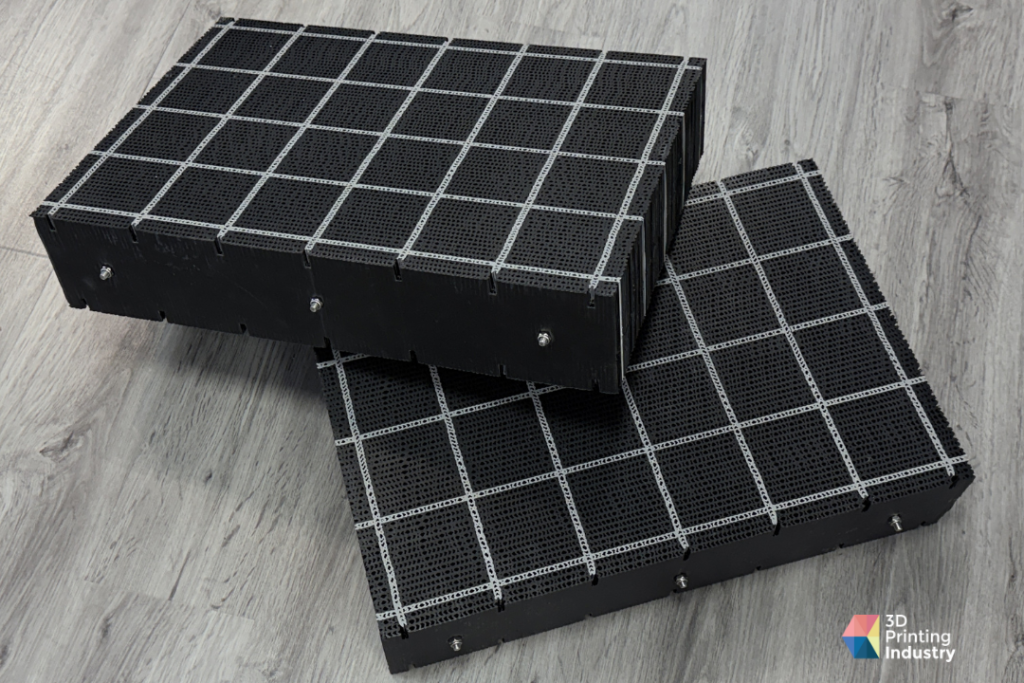

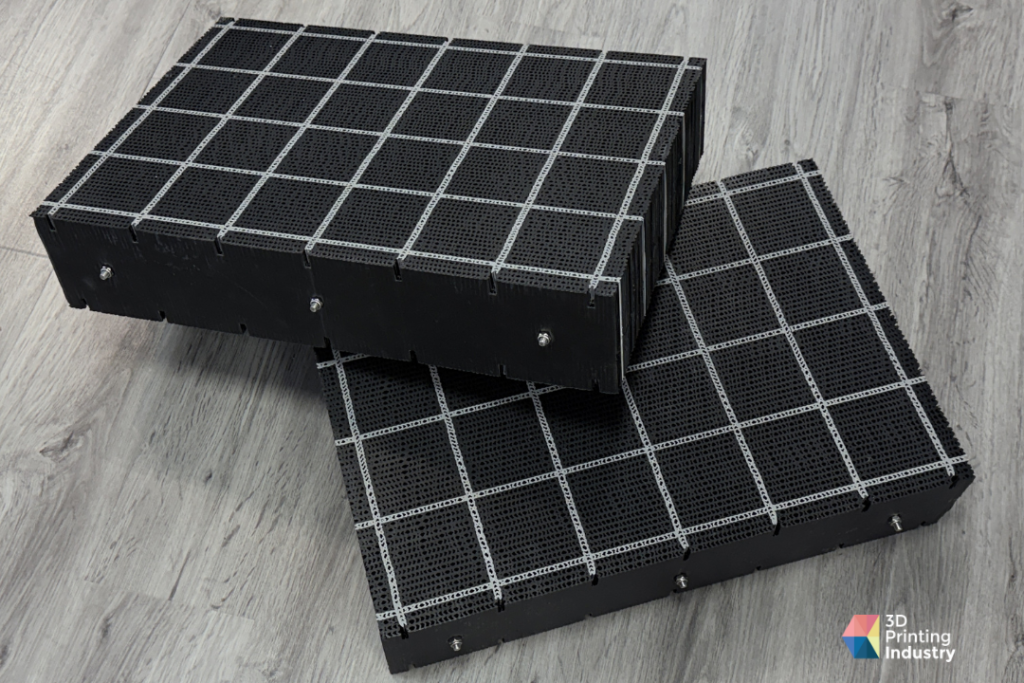

Our group produced 24 small rectangles measuring 20 x 15 mm from 1 mm aluminum. These have been measured and in comparison with the supposed dimension. A succesful system is predicted to ship a imply deviation beneath 0.1 mm and an ordinary deviation beneath 0.05 mm.

WAZER Professional repeatability elements. Photographs by 3D Printing Trade.

The WAZER Professional simply exceeded these benchmarks. The general imply distinction throughout all exams was 0.02 mm, nicely beneath the brink. Furthermore, the usual deviation for each axes was simply 0.011 mm, demonstrating excellent precision. These outcomes verify the brand new waterjet cutter as extremely able to producing high-tolerance cuts.

WAZER Professional repeatability outcomes. Photos by 3D Printing Trade.

The WAZER Professional makes use of a belt-driven system to regulate its axis actions. Nevertheless, system inertia can cut back accuracy throughout fast acceleration or deceleration, resulting in slight deviations, significantly noticeable when reducing round shapes.

Can the WAZER Professional minimize an ideal circle? To search out out, we produced 1.5 mm aluminum round check fashions with diameters of fifty mm, 100 mm, and 150 mm. Every half was fabricated thrice, measured, and in comparison with the goal measurement.

The imply distinction between the X and Y axes for all check elements was simply 0.001 mm, a superb outcome that displays the WAZER Professional’s potential to provide near-perfect circles. The imply deviation throughout all exams was 0.059 mm, nicely beneath the 0.1 mm tolerance threshold. In the meantime, the imply normal deviation was 0.031 mm, beneath the 0.05 mm benchmark.

Measured deviations elevated barely with bigger diameters, indicating the WAZER Professional faces some issue with broad arcing motions. This limitation is typical of belt-driven programs and doesn’t detract from the waterjet cutter’s in any other case spectacular efficiency.

WAZER Professional round trajectory cuts. Photographs by 3D Printing Trade.

Wazer Professional materials compatibility and waterjet reducing functions

Our engineering group additionally evaluated the WAZER Professional’s efficiency throughout totally different supplies and thicknesses in real-world functions.

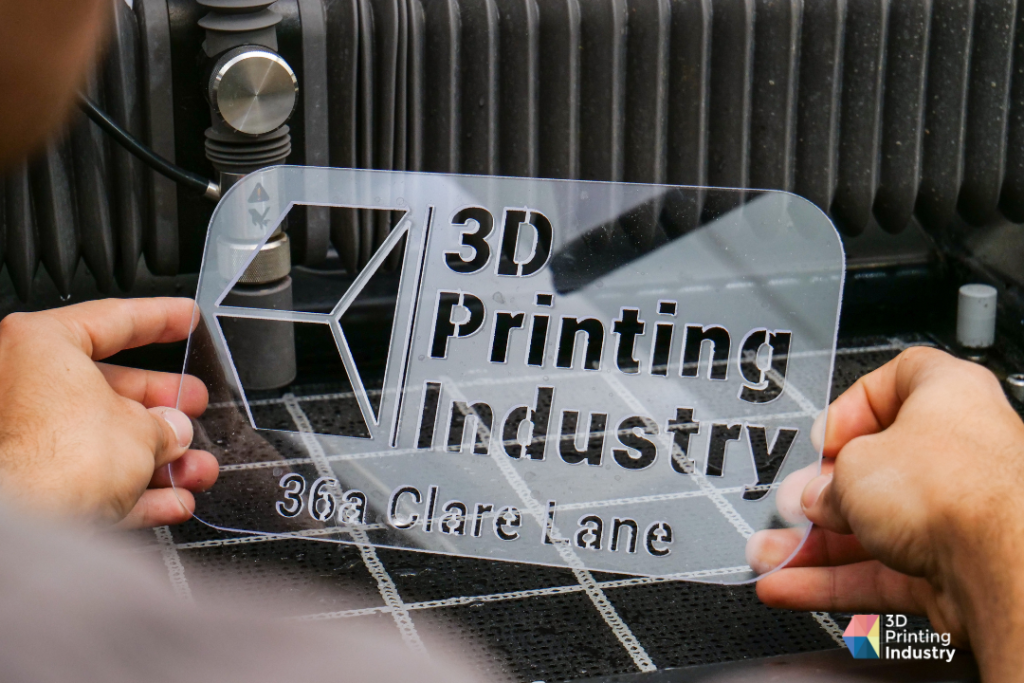

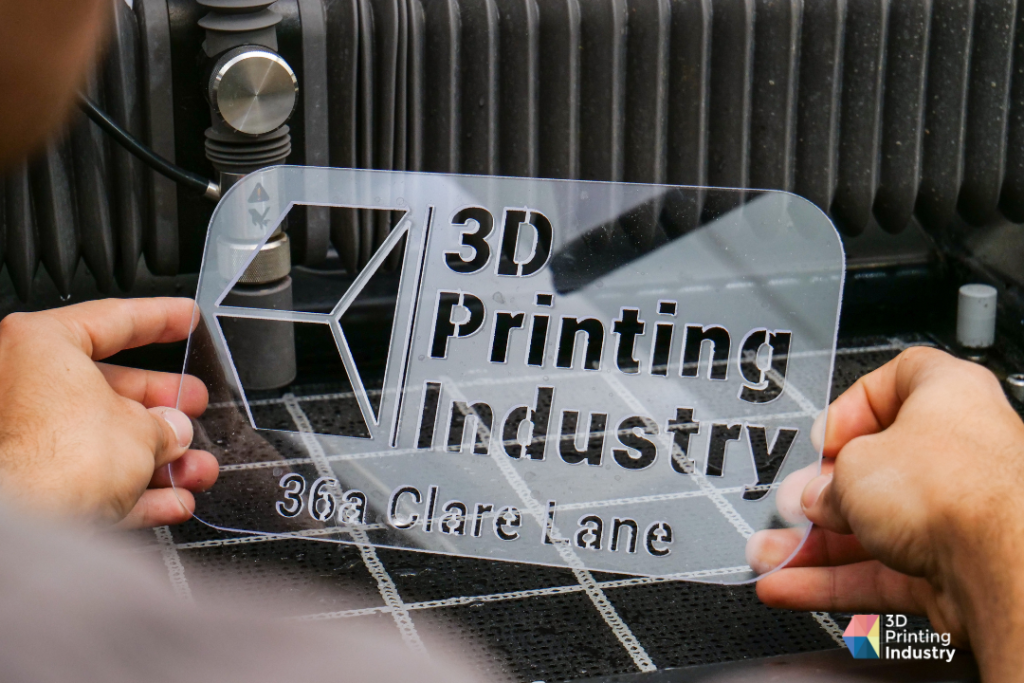

We first produced a 3D Printing Trade stencil utilizing 3 mm polycarbonate (PC). The stencil met our expectations, that includes easy outlines with no vital points. Conventional laser cutters soften PC materials on the contact level, leaving floor defects. When set to High-quality mode, WAZER’s waterjet cutter overcomes this problem, producing clear cuts with no residual artefacts.

Subsequent, we created a stained glass window by reducing and assembling stained glass and acrylic supplies. The intricate geometries on the three stained glass sheets have been minimize with spectacular precision.

Waterjetting utilized no mechanical drive to the glass, considerably decreasing the chance of cracks, chips, or breakage. Moreover, waterjet reducing doesn’t generate warmth, stopping thermal stress and microfractures that might weaken the glass. In the end, each supplies have been assembled seamlessly with minimal effort, reflecting the WAZER Professional’s spectacular precision.

WAZER Professional stained glass window outcomes. Photographs by 3D Printing Trade.

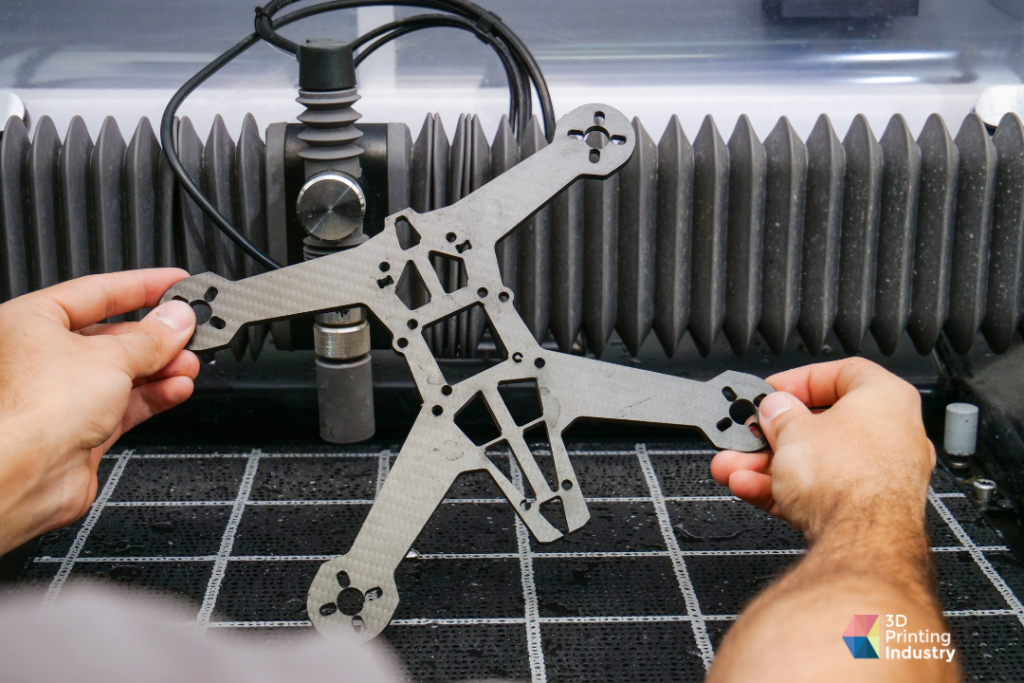

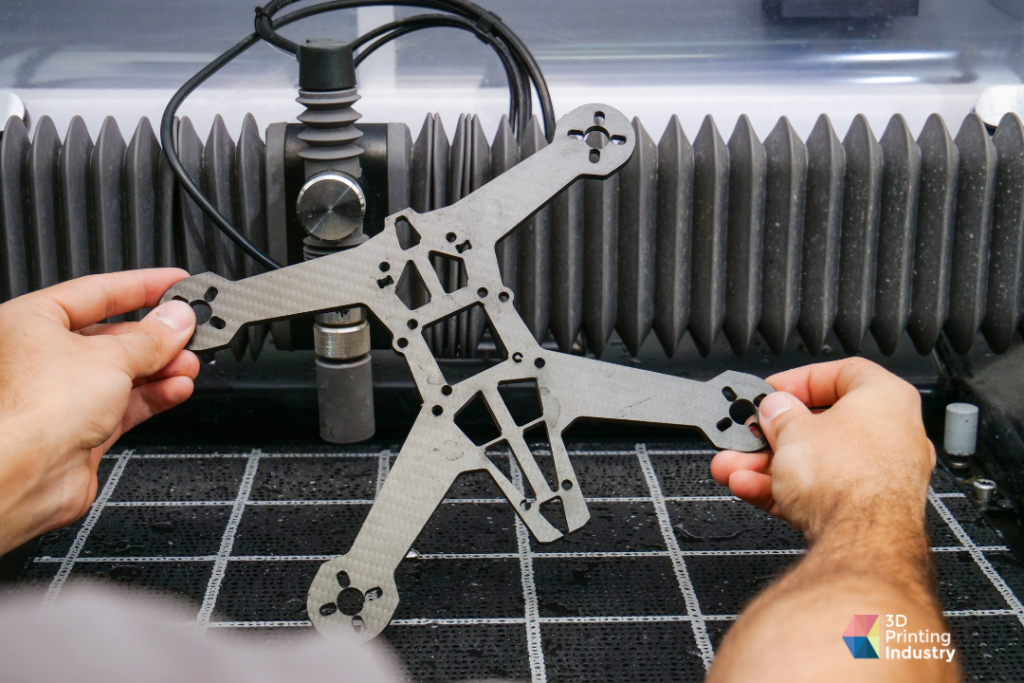

Drone manufacturing is a rising software amid rising client demand. These units typically characteristic frames produced from hardened composite supplies.

To judge the WAZER Professional’s suitability for drone manufacturing, the group produced a body from 2 mm-thick carbon fiber. The machine delivered distinctive precision throughout all geometries, together with small round cut-outs. Nevertheless, water ingress led to layer delamination, a problem linked to the fabric’s high quality. Decrease-grade carbon fibre is extra weak to such defects when waterjet minimize.

WAZER Professional carbon fiber drone body. Photographs by 3D Printing Trade.

A separate body produced by Stable Print 3D utilizing a higher-grade carbon fibre sheet exhibited no delamination. This highlights the WAZER Professional’s functionality to deal with superior composites successfully.

Our group then turned to metallic reducing, starting with copper. As a consequence of its reflectivity, this versatile materials is notoriously troublesome for laser cutters, which create discolouration or thermal distortion. Waterjetting, against this, avoids warmth altogether, delivering exact cuts whereas preserving the metallic’s authentic end.

The WAZER Professional carried out strongly in copper reducing exams. Utilizing 1.5 mm-thick 110 Copper, our group produced a motorbike head gasket in High-quality mode. The outcome exceeded expectations, with clear edges and excessive floor high quality. Minimal post-processing was required, confirming the machine’s suitability for producing practical, high-precision copper parts.

WAZER Professional copper gasket outcome. Photographs by 3D Printing Trade.

We subsequent sought to evaluate the WAZER Professional’s precision when reducing denser supplies. Our group produced a KTM bike bracket utilizing 3 mm aluminum. The waterjet cutter carried out nicely right here. It delivered exact and clear cuts, sustaining wonderful edge high quality with minimal taper.

To make sure success charge and accuracy, we utilized tabs and leads, which have been efficiently generated in WAM with none points. The tabs held the half securely in place throughout reducing, stopping undesirable motion. In the meantime, the leads offered a easy entry level, minimizing edge imperfections.

An aluminum bracket that was minimize utilizing the WAZER Professional. Photographs by 3D Printing Trade.

Subsequent, we examined the WAZER Professional’s efficiency with 1 mm-thick Titanium Grade 2 by producing a mountain bike chainring bracket. Initially, we observed that the toolhead started transferring with out totally penetrating the fabric.

In response, we decreased the reducing pace to 80%, enabling the abrasive stream to pierce the fabric extra successfully. Nevertheless, this adjustment led to an incomplete cut-out, rendering the half unusable. To keep away from such outcomes, customers can run a cut-rate check, accessible by way of the upkeep part of the person interface. This helps decide the optimum pierce time and reducing pace for a given materials, serving to to realize first-time proper cuts.

Mountain bike chainring bracket. Photographs by 3D Printing Trade.

To extend the issue, we tasked the WAZER Professional with reducing a 1 mm-thick brass gasket with intricate options that demanded exact dimensional tolerances. To make sure performance, the half required clear cuts, minimal edge taper, and no distortion.

The WAZER Professional met the duty with ease, delivering the required precision with out seen defects. The gasket was accomplished in simply 9 minutes, demonstrating the system’s functionality to provide high-quality, practical metallic elements with spectacular pace.

A brass gasket minimize utilizing the WAZER Professional. Photographs by 3D Printing Trade.

Lastly, we challenged the WAZER Professional to chop a 1-inch (25.4 mm)-thick aluminum flange.

The half was accomplished in 2 hours and 50 minutes, consuming round 25.4 kg of abrasive. WAZER Professional’s hoppers can solely maintain 19.1 kg of abrasive at a time, which means refills have been required throughout the reducing course of. These interruptions left six seen pierce marks, compromising visible high quality and introducing minor dimensional inaccuracies.

Due to this fact, whereas the WAZER Professional is technically able to reducing 1-inch aluminum, prolonged operations could have an effect on output high quality, demanding extra in depth post-processing for high-precision functions.

A 1-inch aluminum flange minimize utilizing the WAZER Professional. Photographs by 3D Printing Trade.

Democratizing skilled water jet reducing with the WAZER Professional

The WAZER Professional stands out as a powerful addition to the waterjet market. It boasts vital developments in reducing accuracy, usability, and upkeep, making it a superb selection for customers focusing on compact, high-performance waterjet reducing.

At simply $18,999, the WAZER Professional presents a remarkably cost-effective answer. Its intuitive workflow and low upkeep cut back the necessity for in depth coaching. By combining ease of use with industrial functionality, the WAZER Professional lowers the barrier to entry and opens waterjet reducing to a broader group of producers and engineers.

A number of options stood out throughout testing. The upgraded water pump, submerged reducing, backflow sensor, enhanced water hose, and self-cleaning capabilities all work collectively to cut back hands-on upkeep.

The WAM software program additionally impressed us. Its streamlined interface makes importing, processing, and executing reducing recordsdata simple. A complete materials library and well-optimized presets additional assist profitable first-time cuts.

Regardless of its accelerated speeds, the brand new waterjet cutter presents spectacular accuracy, precision, and floor end throughout a slew of difficult supplies. Our repeatability testing yielded a imply distinction of 0.02 mm and an ordinary deviation of 0.011 mm, each nicely beneath our benchmarks. The round trajectory check additional confirmed optimum belt tensioning, with no vital deviations throughout both axis.

Whereas WAM is good for newbies, it lacks the customization and superior enhancing options present in different CNC software program. On the {hardware} aspect, we skilled occasional false triggers with the backflow sensor after resuming reducing. Adjusting the sensor’s sensitivity or including a short lived bypass to disable detection for a couple of minutes after moisture is cleared might resolve this challenge.

Though the WAZER Professional can minimize by 1-inch-thick aluminum, its restricted abrasive capability necessitates mid-operation refills. These interruptions can go away floor defects that require post-processing and will compromise dimensional accuracy.

Regardless of these minor niggles, the brand new waterjet cutter impressed our group. It represents a transparent step up from its already succesful predecessor, the WAZER Desktop. With its reasonably priced value, huge materials compatibility, low upkeep, streamlined workflow, and robust efficiency, the WAZER Professional presents a compelling possibility for these searching for skilled waterjet reducing efficiency with out the premium price ticket.

WAZER Professional technical specs

| Cuttin Space (D x W) | 12 x 18 in305 x 460 mm |

| Minimize Mattress Dimension (D x W) | 13 x 19 in330 x 485 mm |

| Machine Dimension | 34 x 26 x 55 in856 x 648 x 1400 mm |

| Machine Weight | 360 kg (stuffed) 170 kg (empty) |

| Kerf (width of minimize) | 0.044 in1.1 mm |

| Abrasive Price | 0.33 lb/min0.15 kg/min |

| Waterjet Working Stress | 7,400 psi |

| Reducing Supplies | Steel, glass, plastic, composites, tile, rubber, foam |

| Reducing Velocity | 0.5 IPM – 59.1 IPM, relying on supplies and thickness |

| Most Gantry Velocity | 59 IPM1,500mm/min |

| Gantry Positional Accuracy | 0.003 in0.08 mm |

| Most Reducing Thickness | 0.313 in – 1.0 in, relying on supplies and thickness |

| Steady Reducing Time | 90 min (previous to refilling the abrasive hopper) |

| Energy Necessities | 220V / 60Hz (North America)220V / 50Hz (Worldwide) |

| Hydraulic Energy | 2,088 W 2.8 HP |

| Guarantee Interval | 1 12 months |

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the most recent 3D printing information.

You can too observe us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals the WAZER Professional. Photograph by 3D Printing Trade.