On this article, we overview the Artisan, a dual-nozzle FFF 3D printer that options modular CNC machining and laser engraving/slicing capabilities.

Made by Shenzhen-based Snapmaker, the 3-in-1 manufacturing unit combines a sizeable workspace with a robust 40W laser and 200W CNC module able to slicing a broad vary of woods, metals, and plastics.

Launched in 2023, the Artisan’s modular design lets customers rapidly swap between the extruder, CNC, and laser modules. The system additionally helps over ten further equipment, together with a 4-axis rotary module, a 1064 nm infrared laser, and an air air purifier.

The Artisan is offered in two variations: the usual mannequin ($2,599) and the Premium version ($2,999). This overview covers the Artisan 3-in-1 Premium, distinguished by its 40 W laser module, which is 4 occasions extra highly effective than the usual Artisan’s 10 W module.

The Artisan Premium combines dual-nozzle extrusion, all-in-one performance, and a aggressive value to ship a flexible, cost-effective answer for engineers, prosumers, workshops, and makerspaces. Snapmaker’s Artisan 3-in-1 3D printer may be ordered straight from the official Snapmaker web site.

Giant-scale, twin extrusion 3D printing

Regardless of its 3-in-1 performance, the Snapmaker Artisan holds its personal as a devoted 3D printer. Its beneficiant 64-litre construct quantity (400 mm x 400 mm x 400 mm) far exceeds the trade norm of round 10 litres for desktop FFF methods. This expanded capability makes it significantly apt for producing full-scale prototypes and useful end-use elements.

Snapmaker’s Artisan encompasses a dual-extrusion printhead for simultaneous 3D printing with two completely different filaments. This functionality helps multi-material and multi-color tasks whereas minimizing plastic waste and slicing materials prices.

It additionally permits the usage of soluble assist supplies, like PVA or HIPS, alongside the principle filament. Because of this, customers can create complicated geometries and keep away from the post-processing challenges widespread with single-nozzle 3D printers. Each hotends are outfitted with devoted followers to stop filament clogging, complemented by further followers that cool the printed materials, enhancing print high quality and reliability.

When outfitted with customary 0.4 mm brass nozzles, the Artisan helps extrusion temperatures as much as 300°C. Non-obligatory nozzle sizes of 0.2 mm, 0.6 mm, and 0.8 mm are additionally out there, with hardened metal variants advisable for abrasive filaments.

In the meantime, the PEI-coated heatbed encompasses a dual-zone heating system. The central space, measuring 260 x 260 mm, can attain as much as 110°C, whereas the encompassing outer zone tops out at 80°C. This design permits customers to warmth solely the mandatory portion of the mattress, conserving vitality when printing smaller objects. 3D printing Materials compatibility is numerous, spanning PLA, ABS, ASA, PETG, TPU (≥ 90 Shore A), breakaway PLA, PVA, HIPS, nylon, and fibre-reinforced nylons.

The 3D printer’s twin extrusion module encompasses a subtle mixture of a stepper motor, 7.5:1 planetary gear, and twin drive gears for every hotend. This ensures clean and exact extrusion with a most stream charge of 20 mm³/s. Nonetheless, the Artisan’s advisable 3D printing velocity is simply 100 mm/s, slower than most desktop FFF methods in the marketplace.

The Snapmaker Artisan 3D printer twin extruder printhead. Photographs by 3D Printing Business.

Our engineering group was completely impressed by the standard of the Artisan’s {hardware}. It incorporates industrial-grade linear rails and a modern aluminium alloy machine chassis, offering spectacular rigidity throughout manufacturing.

A seven-inch full-colour touchscreen serves because the machine’s central command hub. The interface is each responsive and intuitive, adapting robotically to the chosen mode of 3D printing, laser engraving, or CNC machining. To additional simplify the 3D printing course of, the Artisan employs a proximity sensor for computerized mattress levelling and an optoelectronic change for Z-height calibration. This streamlines the setup course of and improves 3D print accuracy.

Snapmaker Artisan 3D print mattress and touchscreen consumer interface. Photographs by 3D Printing Business.

Modular laser engraving and CNC machining

The Artisan is not any one-trick pony. Customers can manually swap toolheads to alternate between 3D printing, laser slicing, and CNC machining. Snapmaker’s quick-release mechanism ensures the transition is fast, simple, and tool-free.

For laser-related duties, the Artisan Premium’s 40W Laser Module boasts greater than sufficient energy for numerous supplies, together with lime wooden, pine wooden, plywood, beech, walnut, bamboo, and MDF. It can be used to chop and engrave leather-based, material, canvas, corrugated paper, cardboard, plastic, darkish acrylic, and chrome steel. Snapmaker affords over 1000 preset laser vector templates to assist customers get began.

The 40W, 450–460 nm semiconductor laser can reduce by 15mm basswood plywood and 20mm pinewood at speeds of 2-3mm per second. That is thrice deeper than the bottom mannequin’s 10W laser, which manages 5mm of basswood. Snapmaker’s Artisan Premium additionally integrates an Air Help system that cools the laser’s focus, decreasing charring and enhancing slicing precision.

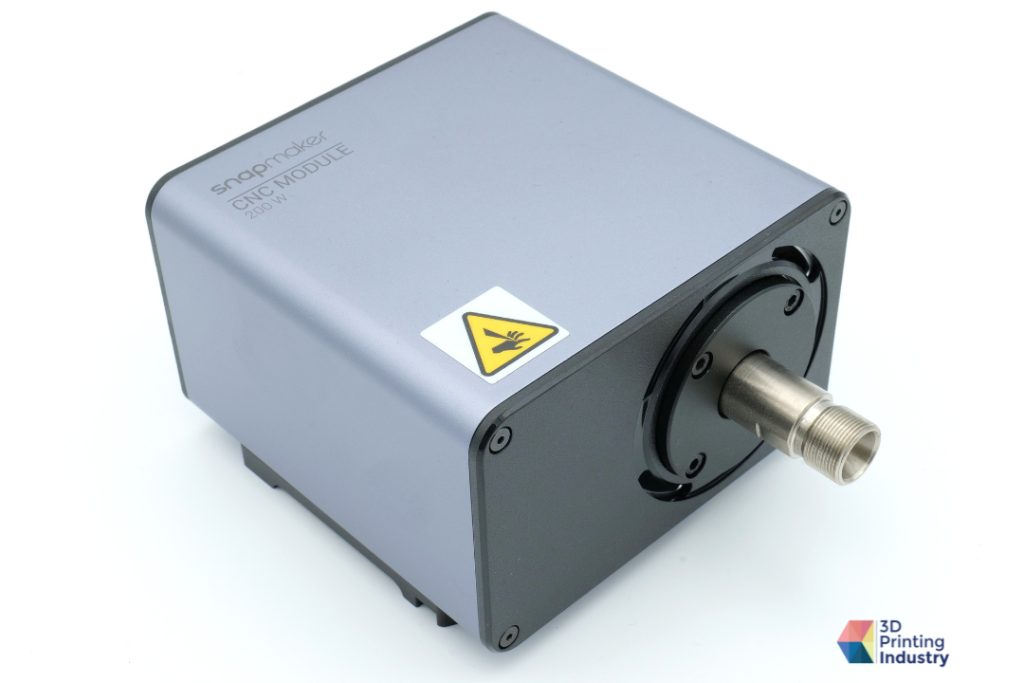

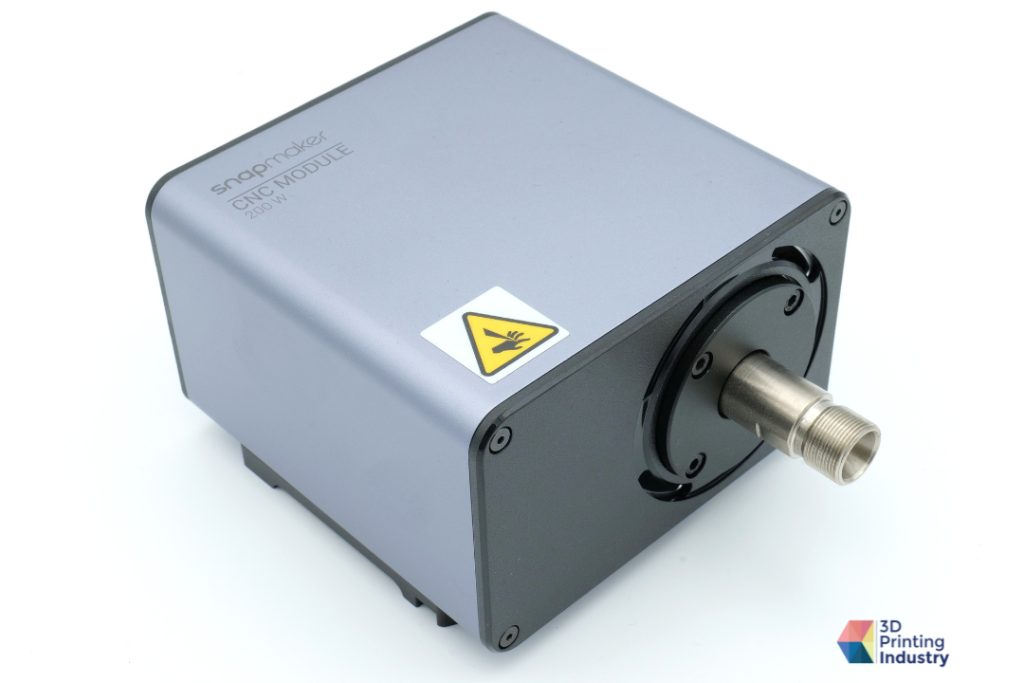

The third pillar of Snapmaker’s 3-in-1 system, the 200W CNC module, proves equally succesful. It handles high-precision machining throughout a variety of supplies, from hardwoods and composites to jade, acrylic, and PCBs. It’s also appropriate with metals reminiscent of aluminium (1000–6000 sequence), brass, and pink copper.

The Artisan Premium’s CNC module delivers thrice the facility and a 50% greater spindle velocity, reaching as much as 18,000 RPM, in contrast with the usual 50W unit. The result’s a 20-fold enhance in machining effectivity for supplies reminiscent of beech wooden. Fitted with an ER11 collet, it helps greater than 100 CNC bits with shank diameters from 1mm to 7mm, providing ample versatility for numerous duties. What’s extra, the high-rigidity linear modules and upgraded one-piece die-cast base plate guarantee a steady CNC expertise, even throughout high-speed operations.

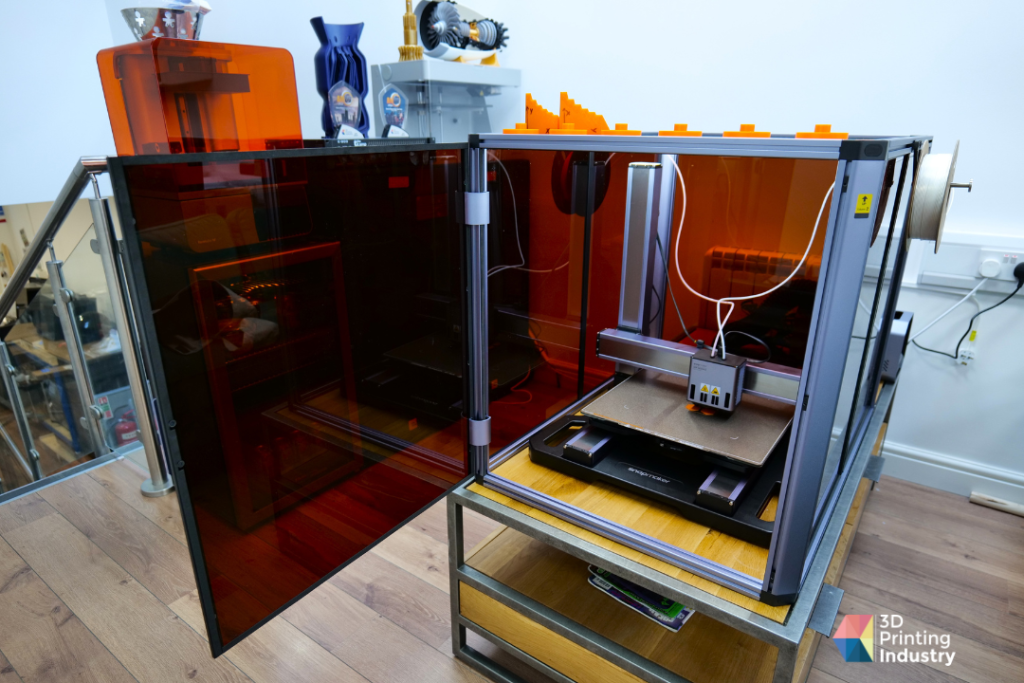

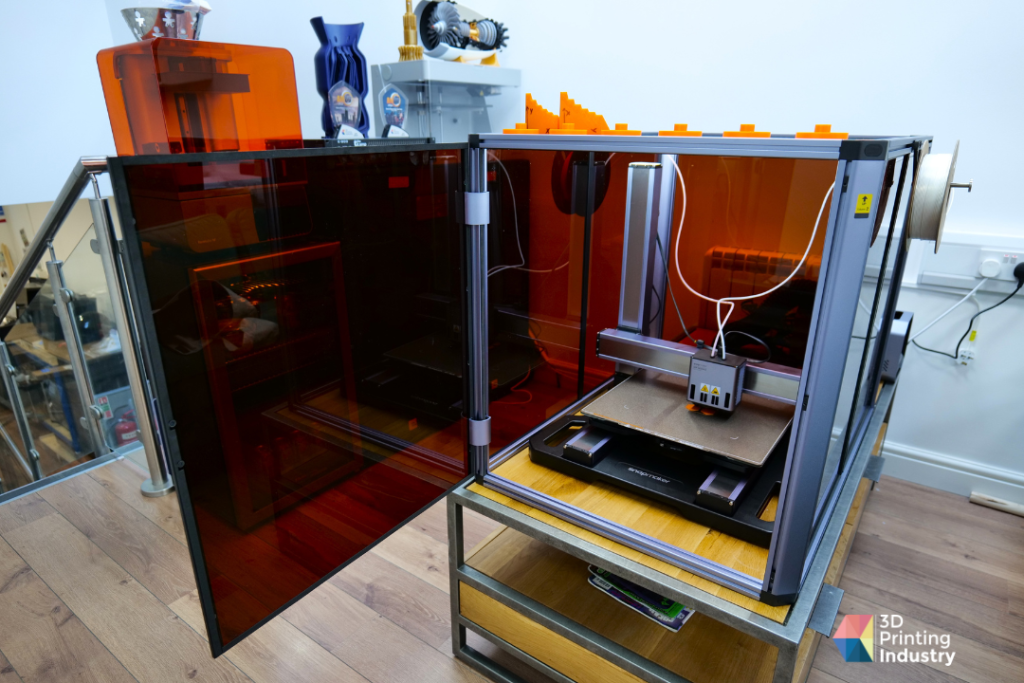

Each the Premium and customary Artisan fashions embrace a laser-proof, dust-proof enclosure, enhancing security and value throughout all three features. It reduces laser hazards from Class 4 to Class 1 and robotically pauses laser or CNC operations when the door opens. The enclosure additionally blocks dangerous laser gentle and incorporates emissions generated throughout milling and laser work. These gases and particles may be readily extracted by way of an exhaust system or filter unit linked to the air flow port.

Throughout 3D printing, the enclosure helps preserve a steady inner temperature, bettering mattress adhesion and making certain balanced filament cooling. This proves particularly helpful when working with warp-prone supplies reminiscent of ABS or polycarbonate (PC).

Snapmaker Artisan enclosure. Photographs by 3D Printing Business.

How good is Snapmaker Luban software program?

Luban, Snapmaker’s proprietary slicing software program, is designed to combine seamlessly with the corporate’s product ecosystem. Luban stands out with its intuitive, user-friendly interface that brings all features collectively in a single seamless setting.

Constructed-in tutorials and prompts make it simple for inexperienced persons to efficiently full 3D printing, laser slicing, engraving, and CNC machining. The house display additionally encompasses a library of ready-to-use fashions, excellent for these seeking to get began rapidly.

The interface is well-organized and straightforward to navigate, with clearly separated sections for instruments and settings. The highest toolbar gives entry to mannequin libraries and printer settings, whereas the fitting panel lets customers modify materials profiles, extruder settings, and print parameters.

Nonetheless, the software program lacks superior options. For instance, it doesn’t enable customers to assign completely different toolpaths, reminiscent of engraving or slicing, to particular elements of a DXF or SVG file. Because of this, customers should separate these components in exterior design software program earlier than importing them. Luban additionally doesn’t embrace a built-in measurement device, making it troublesome to test dimensions like slot widths straight inside the program.

General, we had been impressed by Snapmaker’s Luban software program. Its user-friendly design helps customers of all expertise ranges rapidly obtain nice outcomes.

Snapmaker Luban slicer software program interface. Photos by 3D Printing Business.

Benchmarking the Snapmaker Artisan 3D printer

Our engineering group put the Snapmaker Artisan premium by its paces to see the way it stacks up as a standalone 3D printer.

To start, we 3D printed three pattern fashions from the Snapmaker library. Every half featured a number of segments, permitting us to evaluate the Artisan’s dula extruder, multi-material 3D printing capabilities.

In Luban, assigning colors to particular person mannequin our bodies is remarkably intuitive, making multi-color 3D printing a breeze. The Artisan Premium 3D printed all three fashions in a single shot, taking roughly 16 hours. That is comparatively sluggish in comparison with most trendy desktop FFF 3D printers. Nonetheless, the print high quality was wonderful, with clear surfaces, uniform layer traces, and no seen under-extrusion or gaps.

Artisan Premium 3D printed multi-material pattern elements. Picture and picture by 3D Printing Business.

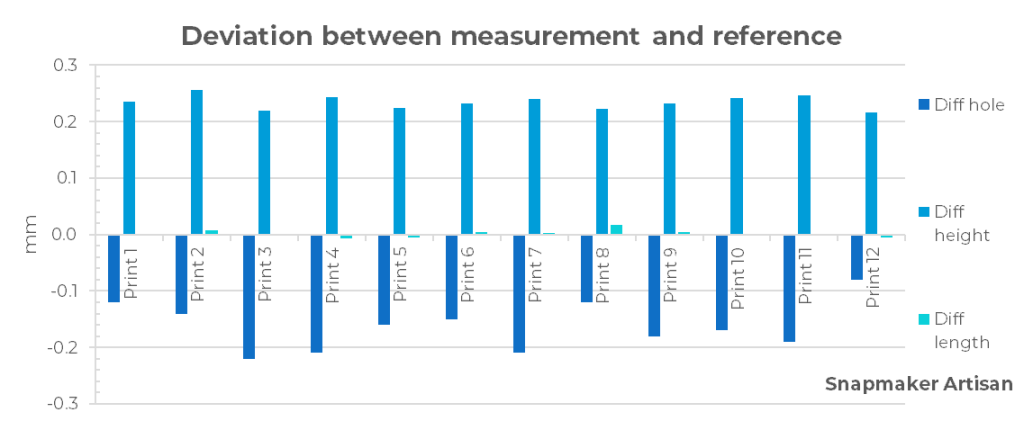

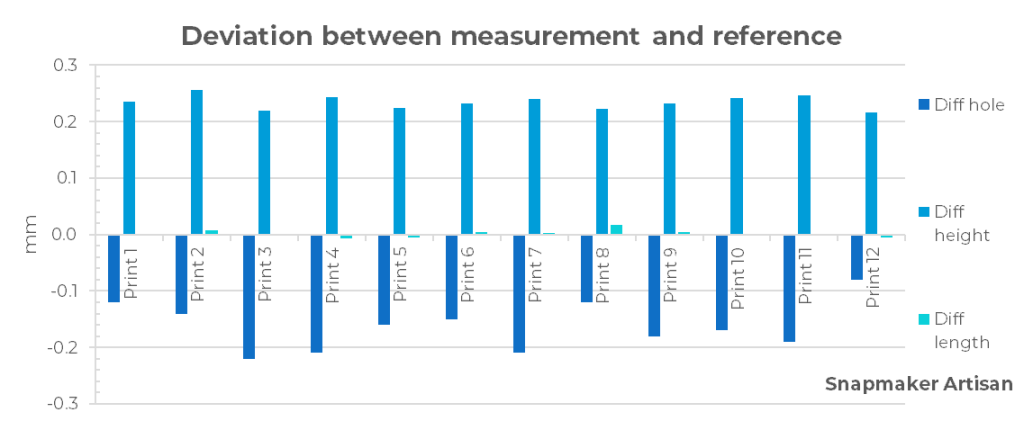

Subsequent, our group examined for repeatability, which is crucial for customers desirous to 3D print batches of similar elements. We 3D printed sq., hexagon, and tube fashions 12 occasions every. These had been then measured and in contrast in opposition to the unique dimensions. Most good-quality 3D printers are anticipated to realize a mean deviation under 0.1 mm and an ordinary deviation underneath 0.05 mm.

3D printed repeatability check elements. Photographs by 3D Printing Business.

The typical deviation for the sq. mannequin was 0.134 mm, which exceeded our benchmark of 0.1 mm. That is disappointing, indicating a comparatively low stage of accuracy. This was primarily resulting from poor outcomes for the interior gap diameter and Z-height. Regardless of this, the usual deviation got here to 0.021 mm, effectively inside the 0.05 mm goal, suggesting wonderful precision and consistency.

Equally, the hexagon exams revealed below-average dimensional accuracy, with a mean deviation of 0.132 mm, however robust precision, evidenced by a low customary deviation of 0.018 mm. In distinction, the tube fashions delivered significantly better outcomes, with a powerful common deviation of 0.064 mm, effectively under the 0.1 mm goal, and an ordinary deviation of simply 0.011 mm, confirming excessive 3D printing precision.

The distinction between measurement and reference for the hexagon (first picture) and tube fashions (second picture). Photos by 3D Printing Business.

Most FFF 3D printers have issue printing excellent circles due to uneven belt pressure and G-code limitations. To check whether or not the Snapmaker Artisan can 3D print an ideal circle, we carried out a round trajectory check. We 3D printed a number of fashions with round sections measuring 100 mm, 65 mm, and 20 mm in diameter. These had been measured and in comparison with the goal dimensions. A mean deviation under 0.1 mm for each the X and Y axes is taken into account an excellent outcome.

3D printed round trajectory check. Photographs by 3D Printing Business.

These check outcomes present distinctive efficiency, delivering each exact and extremely correct outcomes. The typical distinction throughout all exams was solely 0.014 mm, effectively under the 0.1 mm tolerance restrict. An ordinary deviation of 0.013 mm demonstrates wonderful repeatability, comfortably inside the 0.05 mm tolerance. This confirms that the slicer successfully preserved the STL mesh’s integrity, retaining the round profiles dimensionally steady and extremely correct.

Snapmaker Artisan round trajectory outcomes. Photos by 3D Printing Business.

The Snapmaker Artisan 3D printer encompasses a beneficiant 400 x 400 x 400 mm construct quantity, surpassing many desktop FFF 3D printers. Can customers take full benefit of this marketed house? To seek out out, we 3D printed a tower with a goal Z-axis peak of 400 mm. The ultimate half measured 399.95 mm, almost similar to the supposed measurement, confirming that the Artisan can absolutely obtain its marketed construct peak. The print high quality was wonderful, with constant layers and minimal ringing, a typical defect in tall prints brought on by vibrations.

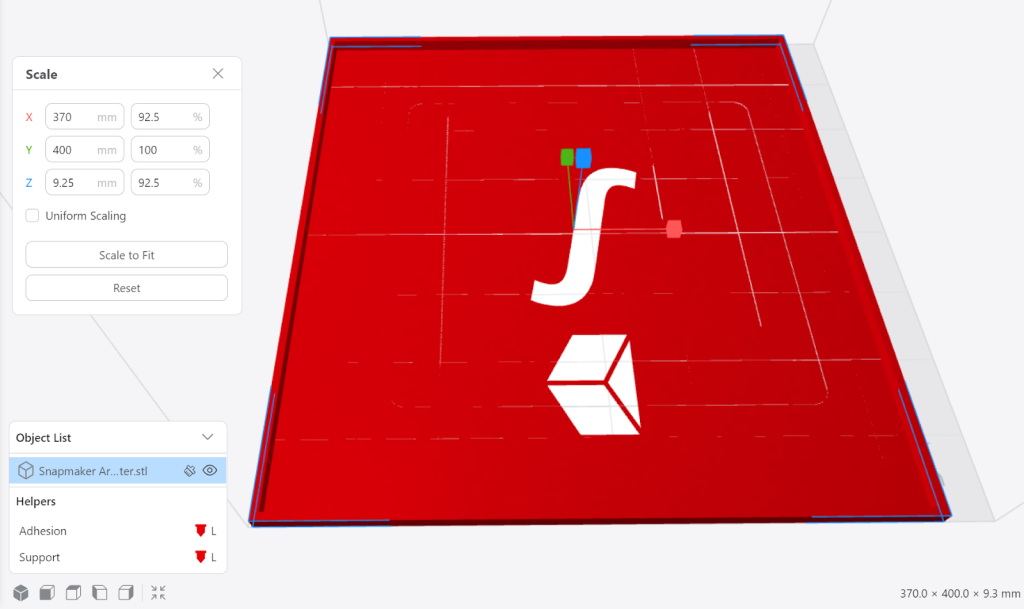

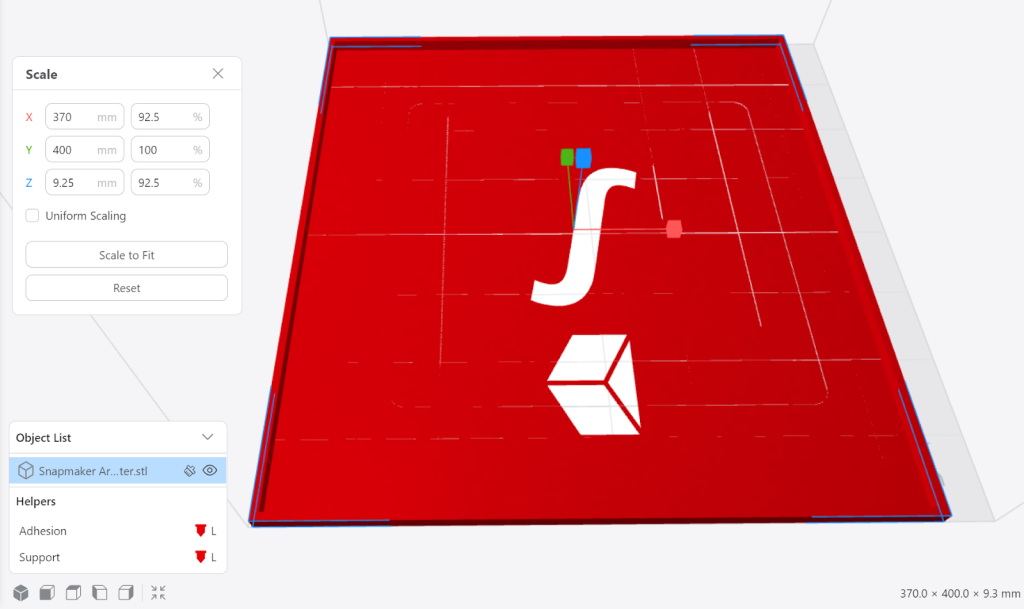

We subsequent 3D printed a fringe check to evaluate whether or not customers can make the most of the total 400 x 400 mm marketed construct plate. Our group seen a greyed-out exclusion zone inside the construct space, accompanied by a warning that the mannequin exceeds the workspace boundaries. After adjusting the mannequin, we discovered that in dual-extrusion mode, the efficient print space is about 400 x 370 mm. Solely the fitting nozzle can absolutely entry the 400 x 400 mm construct house.

Snapmaker Luban explains this in its assist guide, recommending customers assign all duties to the fitting nozzle to remove the exclusion zone. As soon as we did this, the slicer accepted the full-size mannequin, confirming the Artisan can use its whole construct quantity when printing with the fitting nozzle solely.

Snapmaker Artisan 3D printed perimeter check. Picture by 3D Printing Business.

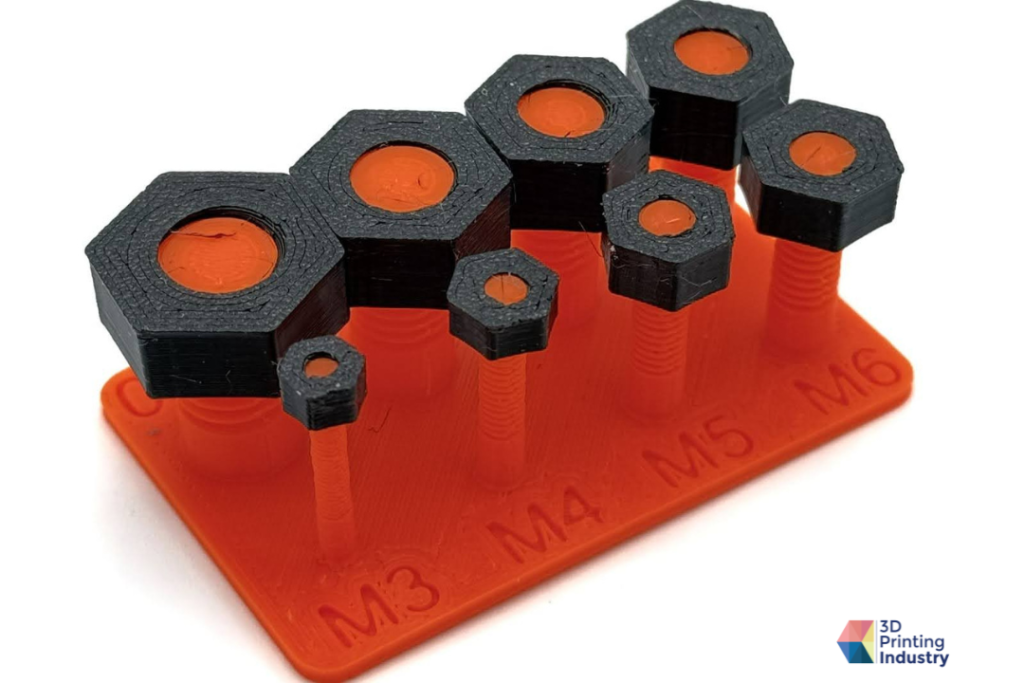

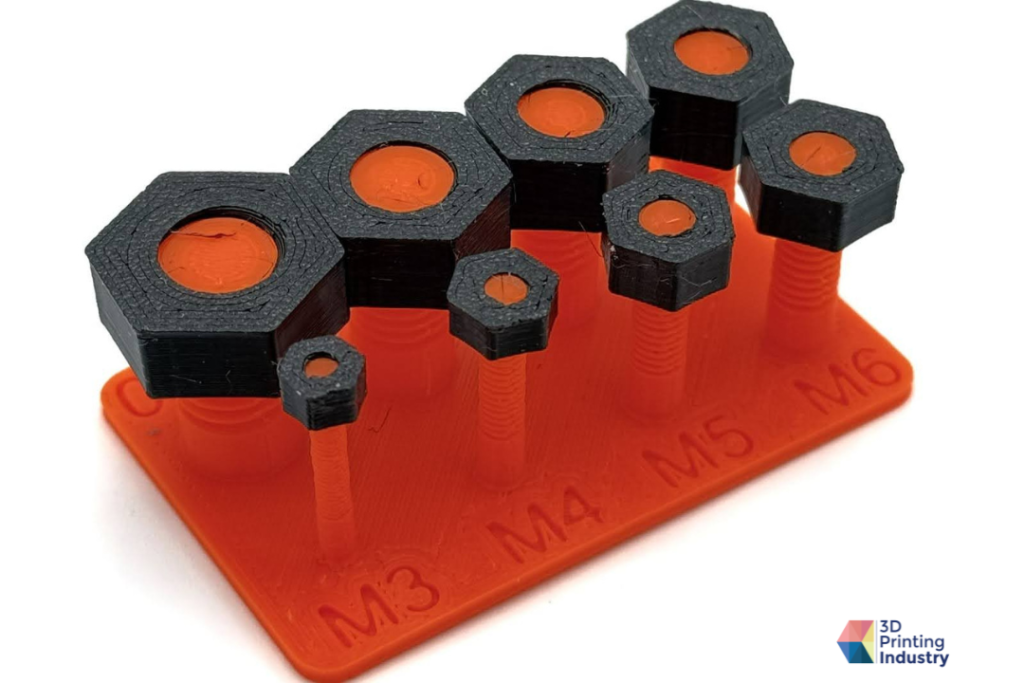

How effectively does the Artisan deal with small, detailed elements? We 3D printed eight useful nut and bolt fashions with thread sizes starting from M10 to M3. Impressively, the Snapmaker Artisan accomplished your complete thread check with none useful points, precisely printing each thread.

The thread palette was printed in PLA, whereas the corresponding nuts had been produced in PETG. Regardless of the distinction in supplies, there was no important impression on dimensional accuracy or match. This demonstrates the Artisan’s wonderful precision and materials compatibility.

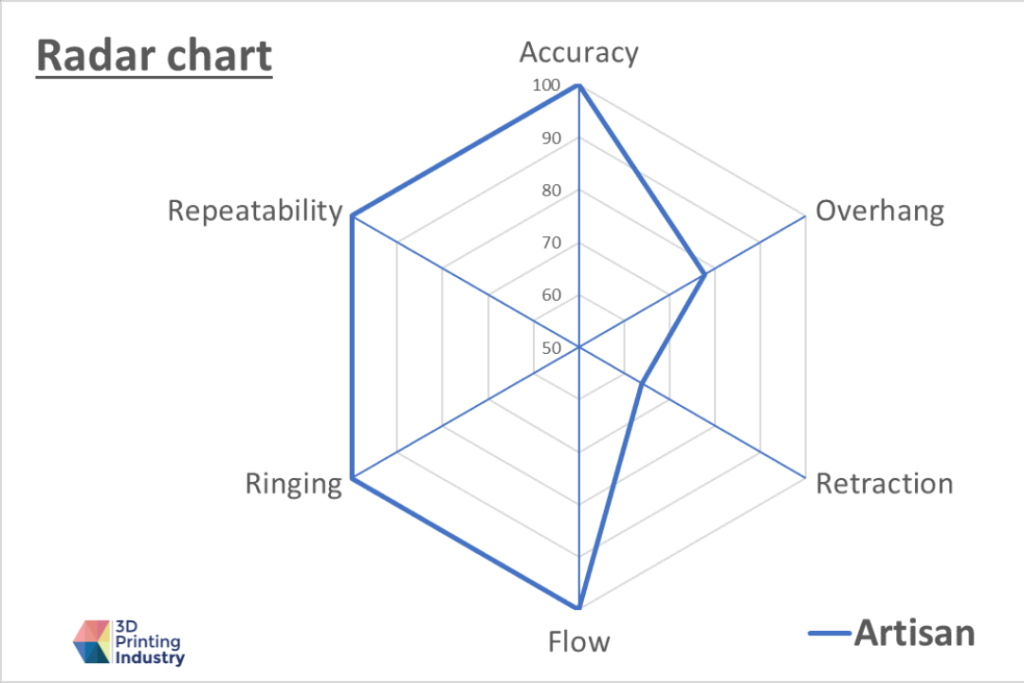

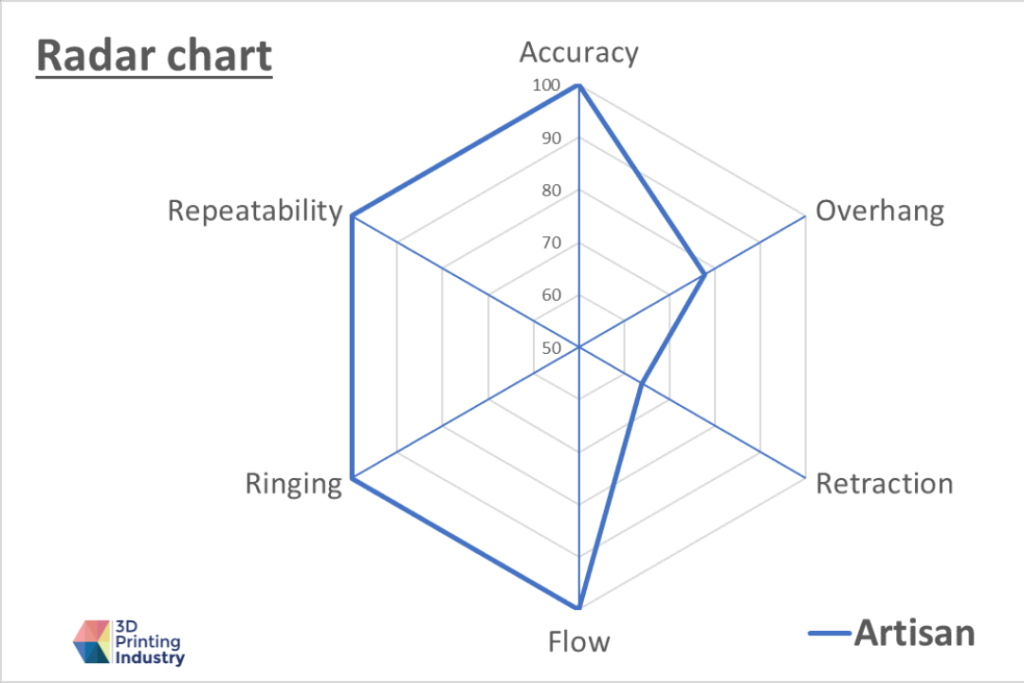

Subsequent, we produced our in-house 3DPI check in PLA, which we 3D printed in PLA at 100 mm/s. The Artisan achieved a powerful rating of 83/100. This represents a major enchancment over the Artisan’s predecessor, the Snapmaker 2.0, which scored 63/100.

The Artisan scored flawlessly within the accuracy, repeatability, ringing, and stream classes, assembly all dimensional targets with minimal deviation. Notably, the X and Y axis outcomes had been almost similar, confirming the machine’s strong mechanical stability.

Snapmaker Artisan 3D printed 3DPI check. Photographs by 3D Printing Business.

Nonetheless, whereas the Artisan produced clear overhangs as much as 50°, noticeable defects like layer drooping appeared at 60°. That is considerably disappointing, as most well-tuned FFF 3D printers can sometimes deal with overhangs as much as 55° with out points.

The spike part of the 3DPI check confirmed important stringing and oozing, particularly from the bottom to the tip of the spikes, together with seen residue on the seam traces. This means that the default retraction settings are usually not well-optimized, probably resulting from excessive nozzle stress and insufficient filament pullback.

Actual-world, 3D printing functions

Our group additionally assessed the Artisan’s efficiency in real-world 3D printing functions.

We began with a bike clutch basket locking device, a specialised gadget utilized by mechanics to safe the crankshaft and stop rotation when loosening or tightening the clutch nut. The Artisan’s dual-extrusion printhead permits our engineers to mix cost-effective PETG filament for the physique of the half and high-strength polycarbonate (PC) for the load-bearing sections.

The multi-material half exhibited a wonderful floor end, with clean materials transitions and no seen defects on the interface. Inspection revealed no indicators of delamination, indicating robust thermal compatibility and efficient interlocking between supplies. The clutch holder device exhibited the required stiffness and mechanical integrity, making it a completely useful half.

3D printed motorbike clutch basket locking too. Photographs by 3D Printing Business.

We additionally 3D printed a trolley bracket prototype. The half, which might often be constituted of aluminum, was 3D printed with each customary PLA and Breakaway Help PLA for assist buildings.

The half confirmed noticeable stringing and oozing artifacts on the floor of the principle half, brought on by the assist materials. Molten assist materials intermittently oozed throughout printing, depositing wonderful strings, a few of which grew to become embedded between layers of the principle physique. This resulted in a less-than-ideal floor end for a clear prototype.

Regardless of the floor points, the Artisan accomplished the print with out interruption. The breakaway helps detach simply by hand, leaving clean, well-defined interface surfaces. Overhang undersides confirmed constant layering with minimal scarring or tearing after assist removing.

3D printed trolley bracket prototype. Photographs by 3D Printing Business.

Lastly, we 3D printed a multi-material gear utilizing ABS and PC filament for the principle physique, and nylon for the gear enamel. The half yielded combined outcomes. Whereas the fusion of nylon and ABS/PC was profitable, general print high quality was missing.

The nylon part’s prime floor confirmed seen gaps, probably resulting from a partial clog that restricted stream, leading to solely 50% top-layer completion. Help buildings in ABS/PC additionally proved problematic, failing to separate cleanly and inflicting minor layer tearing at inner contact factors. Although usable for early prototyping, the half fell in need of final-use requirements.

Testing Artisan’s laser engraving and CNC machine capabilities

Past 3D printing, we evaluated the Artisan Premium’s 40W laser with a sequence of exams. First, we ran Snapmaker’s pre-loaded check file in Luban, which mixes engraving and slicing to supply a protractor and ruler. Utilizing plywood as the fabric, we created two units, one with air help enabled and one with out, to match efficiency.

The outcomes had been evening and day. Air help produced considerably higher outcomes, with spectacular slicing and engraving high quality. Burn marks had been distinguished alongside the sides of the non-assisted mannequin, whereas the air-assisted model produced clear, sharp cuts with no seen scorching.

Laser engraving check file. Photographs by 3D Printing Business.

Subsequent, we carried out the laser engraving materials check included within the Luben software program. This assesses a spread of various laser energy intensities and speeds. We used the 5.2 mm-thick basswood slab equipped with the Snapmaker Artisan, aspiring to establish the optimum velocity and energy settings for each laser engraving and slicing on pure wooden. Within the preliminary exams, the default engraving velocity of 720 mm/min proved too sluggish for this specific thickness and materials kind.

After some troubleshooting, we discovered {that a} minimal velocity of 1300 mm/min is required to stop overheating. For engraving, the very best outcomes had been achieved at 6000 mm/min with an influence output of 10%. Whereas, laser slicing performs greatest at 1300 mm/min at 90% energy.

Our engineering group then used the laser cutter to create a four-piece cellphone stand utilizing 3.4 mm-thick plywood. The Artisan Premium accomplished the slicing course of effectively, demonstrating each velocity and accuracy. Its highly effective laser cleanly reduce by the plywood with out leaving important burn marks or charring.

Nonetheless, the convenience of meeting stood out probably the most. The construction held collectively firmly, confirming that the Artisan maintained constant slicing tolerances all through the job. Subsequently, Snapmaker’s 3-in-1 providing is well-suited for jobs requiring tight-fitting joints, reminiscent of jigs, stands, or interlocking wooden designs.

Laser-cut picket cellphone stand. Photographs by 3D Printing Business.

For engraving exams, we used the Artisan to use designs to numerous flat surfaces, together with a 3D printed PLA half and an aluminum tray. Each exams succeeded: the PLA half displayed a crisp customized emblem, whereas the aluminum engraving, although barely uneven, remained legible and featured a scannable QR code.

Artisan Premium laser engraving exams. Photographs by 3D Printing Business.

We then turned to CNC machining, beginning with wooden. Utilizing the Snapmaker-supplied HDF sheet and the included check file, the Artisan delivered spectacular outcomes. All cuts had been clear and exact, with minimal edge fraying or chipping, robust indicators that the feed charges and spindle velocity had been well-matched to the fabric.

HDF CNC check. Photographs by 3D Printing Business.

After this, we moved to MDF, CNC slicing a 12 mm deep sample right into a medium-density fiberboard sheet. Throughout setup, we encountered persistent simulation errors when importing STL information into Luban’s CNC module. Regardless of makes an attempt to resolve the difficulty by way of Snapmaker assist and workarounds, the glitches persevered.

We proceeded by choosing the cleanest simulation and milled a fancy 12 mm-deep sample into MDF utilizing a V-bit. Though we diminished the depth and elevated the step-over to shorten the job from 90 to twenty hours, the outcome remained exact and visually detailed. Whereas the Artisan carried out effectively, Luban’s poor simulation constancy could cause points for complicated CNC duties.

CNC MDF check simulation defects and milled MDF. Photographs by 3D Printing Business.

We concluded our CNC testing by evaluating the Artisan’s efficiency on metallic. The check featured a precision round engraving across the fringe of a pre-cut aluminum flange. This was a transparent success. The machine adopted the toolpath with excessive accuracy, producing a clear, uniform groove appropriate for seating a rubber seal. The 45-minute job ran easily with none irregularities, demonstrating the Artisan’s functionality for exact metallic engraving and confirming its suitability for light-duty mechanical functions.

CNC-engraved aluminum half. Photographs by 3D Printing Business.

Snapmaker Artisan Premium: A workshop-ready fabrication device

Finally, Snapmaker Artisan Premium 3-in-1 is a good addition to any workshop setting. It affords an accessible, high-quality, and cost-effective answer for these requiring 3D printing, laser engraving and slicing, and CNC machining.

All through our testing, the Artisan delivered stable efficiency throughout all modalities. Its 3D printer delivers commendable dimensional accuracy and structural consistency, positioning it as a reliable device for prototyping and precision-driven duties. The twin-extrusion toolhead unlocks simple multi-material 3D printing, with spectacular interlayer adhesion and seamless transitions.

Nonetheless, the 3D printer’s thermal regulation and retraction settings require additional optimization, particularly when dealing with complicated geometries and unsupported options. Though it carried out effectively in round trajectory exams, its repeatability was inconsistent. Extra shortcomings had been noticed in bridging and retraction high quality, and the comparatively sluggish print velocity could frustrate customers looking for quick turnaround for speedy prototyping.

When paired with the optionally available air help system, the laser module achieved excessive ranges of precision with clear edges and minimal floor charring. The CNC module additionally carried out admirably, slicing wooden composites and even aluminium with an excellent floor end and dimensional accuracy.

Snapmaker’s Luban software program was intuitive and straightforward to make use of, making it perfect for customers wanting to interrupt into laser slicing, engraving, and CNC machining. Nonetheless, these with extra expertise in these areas could discover the dearth of superior instruments irritating.

Regardless of some room for enchancment, the Snapmaker Artisan Premium is a well-designed fabrication device that bridges the hole between shopper desktop 3D printing {and professional} manufacturing.

Technical specs of the Snapmaker Artisan 3-in-1 Premium

| 3D Printer | |

| Machine dimensions | 580 mm x 620 mm x 634 mm |

| Dimensions with enclosure | 665 mm x 943 mm x 705 mm |

| 3D printer construct quantity | 400 mm x 400 mm x 400 mm |

| 3D printer weight | 1 kg |

| Hotend max temperature | 300°C |

| Mattress max temperature | 110°C |

| Extruders | Twin extrusion |

| Nozzle | ⌀0.4 mm, Brass |

| Connectivity | Wi-Fi, USB Cable, USB Flash Drive |

| Software program compatibility | Snapmaker Luban and third-party |

| Laser Engraving and Chopping | |

| Laser output | 40W |

| Laser electrical energy | 125W |

| Laser kind | 450-460nm semiconductor |

| Security class | Class 4 with out enclosureClass 1 with enclosure |

| CNC Module | |

| CNC work space | 400 mm x 400 mm x 400 mm |

| CNC energy | 200W |

| Most spindle velocity | 18,000 RPM |

| Suitable supplies | Hardwood, Softwood, CF, Acrylic, Aluminium, Brass, Pink Copper |

| Shank diameter | 0.5–6.35 mm |

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

You too can comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals The Snapmaker Artisan. Picture by way of Snapmaker.