Ahead-looking: Researchers on the College of Massachusetts Amherst have developed a laser-based approach to align 3D semiconductor chips, doubtlessly overcoming a longstanding problem in chip manufacturing. The strategy employs concentric metalenses to generate holograms that reveal misalignment between chip layers at a a lot smaller scale than beforehand attainable.

Semiconductor chips have historically been manufactured in two dimensions. However as units turn into extra highly effective and compact, the business is more and more turning to 3D chip designs, which contain stacking a number of 2D layers. This strategy introduces important technical challenges – most notably, the necessity to align every layer with excessive precision. Even slight misalignment can compromise chip efficiency.

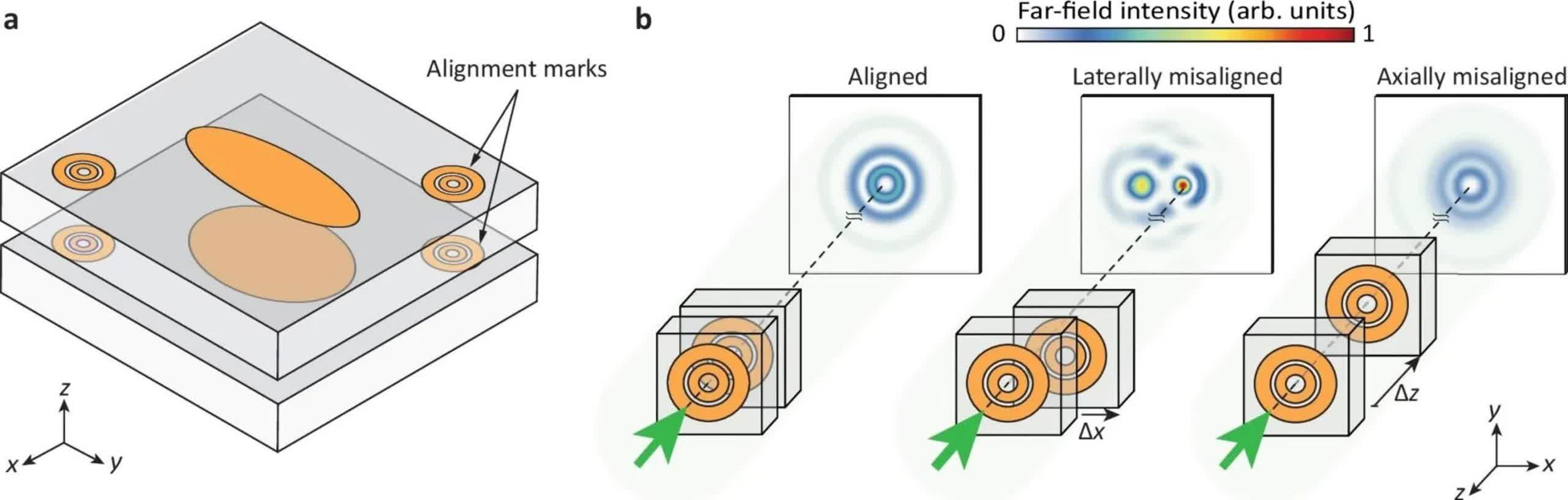

The standard strategy for aligning two layers is to look with a microscope for marks, equivalent to corners or crosshairs, on the 2 layers and to attempt to overlap them, stated Amir Arbabi, affiliate professor {of electrical} and laptop engineering at UMass Amherst and senior writer of the research.

Nonetheless, this microscope-based course of is proscribed by the bodily hole between layers and the necessity to refocus, which might truly trigger the chips to shift and misalign additional. The microscope can’t see each crosshairs in focus without delay as a result of the hole between the layers is a whole lot of microns. The movement required to refocus between layers can result in chip displacement, defined Maryam Ghahremani, the research’s lead writer.

Microscopes are additionally constrained by the diffraction restrict, which restricts the smallest resolvable options to about 200 nanometers.

The brand new technique developed at UMass Amherst bypasses these constraints. By embedding alignment marks product of concentric metalenses onto every chip and shining a laser by means of them, the researchers generate two interfering holograms. The ensuing interference sample gives a direct visible cue in regards to the chips’ alignment ,together with each the course and magnitude of any misalignment.

“This interference picture reveals if the chips are aligned or not, in addition to the course and the quantity of their misalignment,” Ghahremani stated.

The system’s precision exceeded preliminary expectations. Whereas the staff initially aimed for 100-nanometer accuracy, the strategy was in a position to detect misalignments as small as 0.017 nanometers alongside the horizontal axis and 0.134 nanometers alongside the vertical axis. “Take into account you may have two objects. By trying on the mild that goes by means of them, we are able to see if one moved by the scale of an atom with respect to the opposite one,” Arbabi stated.

This stage of precision may have main implications for the semiconductor business, the place alignment errors stay a persistent and expensive problem. Decreasing the technical and monetary limitations to ultra-precise chip alignment may make superior manufacturing extra accessible to smaller firms and startups.

The researchers additionally counsel that the approach could possibly be tailored for compact, low-cost sensors. “Many bodily portions that you simply wish to detect might be translated to displacements, and the one factor you want is an easy laser and a digital camera,” Arbabi stated. Functions may embody strain sensors, vibration detectors, and different units that monitor motion or environmental adjustments.