May reshape automotive manufacturing by combining excessive energy with decrease manufacturing prices utilizing superior 3D printing strategies.

A research from Carnegie Mellon College (CMU) and the Massachusetts Institute of Know-how (MIT) has launched a novel printable aluminum alloy system that guarantees to rework the automotive business by balancing excessive energy with lowered prices. Aluminum alloys are broadly favored in automotive and aerospace sectors for his or her strength-to-weight ratio and affordability. Nevertheless, their efficiency at excessive temperatures — essential for parts like engine pistons and jet engine fan blades — is proscribed. Most standard aluminum alloys lose energy at elevated temperatures and lack cost-effective, sustainable design methods.

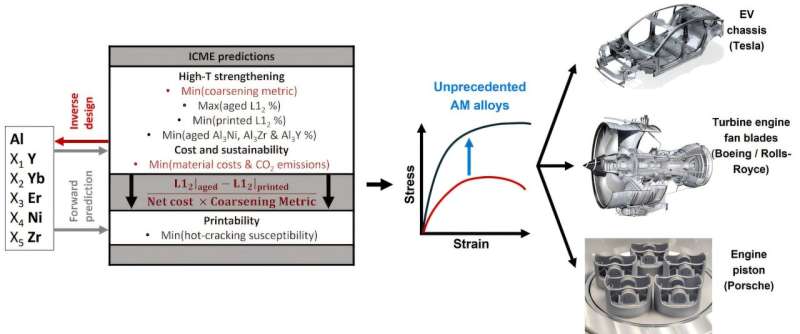

In distinction, alternate options like titanium alloys, though efficient, are practically twice as costly and tougher to machine. To deal with these challenges, CMU and MIT researchers leveraged computational simulations and optimization algorithms to design aluminum alloys appropriate with additive manufacturing (AM). Their work introduces a brand new alloy household based mostly on aluminum, nickel, erbium, zirconium, and yttrium (Al-Ni-Er-Zr-Y). This technique gives as much as 95% of the energy of benchmark printable aluminum alloys whereas delivering a projected 15% price discount. A second formulation optimized for room temperature use achieves equal energy at simply 20% of the benchmark price.

The crew employed a high-throughput Built-in Computational Supplies Engineering (ICME) framework based mostly on CALPHAD modeling, coupled with machine studying, to research composition-process–construction–property relationships. Laser-based AM strategies, which allow fast solidification, had been instrumental in forming distinctive microstructures that improve the fabric’s energy by exploiting metastable phases that solely type underneath these quick cooling situations.

“This improvement may considerably affect the automotive sector, the place there’s excessive demand for supplies that mix efficiency, sustainability, and cost-efficiency,” mentioned Assistant Professor Mohadeseh Taheri-Mousavi of CMU, who co-led the research with Ph.D. scholar Benjamin Glaser. This analysis opens the door to next-generation light-weight, printable aluminum alloys tailor-made for high-demand industrial purposes with a robust emphasis on sustainability and cost-effectiveness.