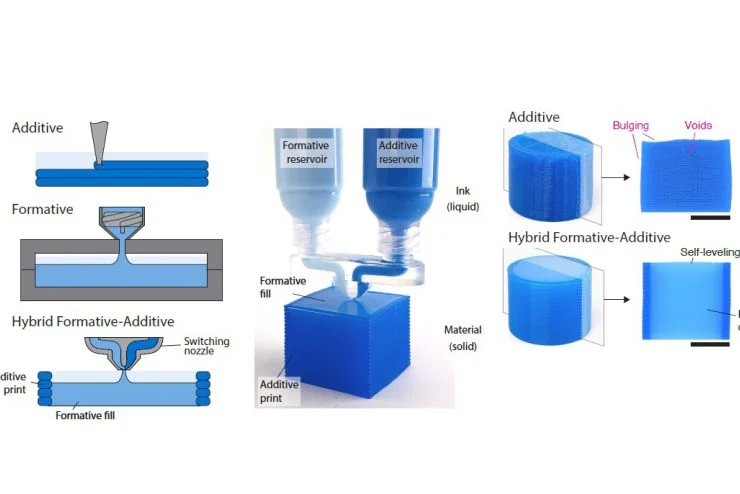

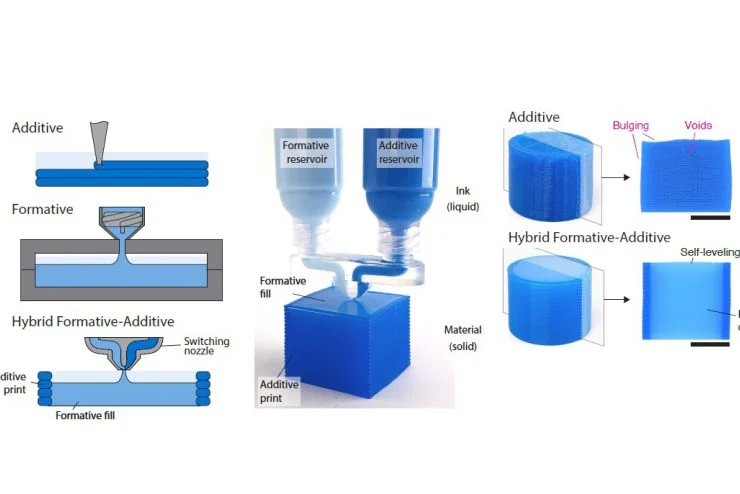

Johns Hopkins researchers have developed a brand new method to 3D printing that mixes the precision of additive manufacturing with the pace of conventional molding methods. The strategy, known as Hybrid Formative-Additive Manufacturing (HyFAM), was created by a workforce from the Division of Civil and Methods Engineering on the Whiting Faculty of Engineering. Their analysis was not too long ago printed in Superior Supplies.

“As a substitute of viewing additive and formative manufacturing as competing strategies, we had the thought to marry the 2,” mentioned Jochen Mueller, CaSE assistant professor and principal examine creator. “By combining the advantages of every, we created a brand new manufacturing technique that additionally overcomes a few of their main drawbacks.”

HyFAM works through the use of a casting-like course of for bulk sections the place fantastic element isn’t mandatory, whereas using conventional 3D printing methods for detailed areas like outer surfaces. This mix could make manufacturing as much as 10 to twenty occasions sooner for objects with important cast-like fill, and roughly twice as quick for detail-heavy prints, in line with Mueller. The strategy helps keep away from the inefficiency of printing each half when solely sure sections require precision.

The workforce has examined HyFAM with varied supplies together with silicone, ceramics, metals, epoxy, cement, clay, and chocolate. The method required cautious management of fabric move and consistency to make sure even filling. It additionally addresses frequent 3D printing issues by serving to bond printed sections collectively uniformly.

Nathan Brown, a doctoral candidate and first creator of the paper, defined the benefit: “Additive manufacturing gives important element, however while you use a small nozzle to attain it, all the course of slows down. This turns into an actual hinderance in elements with giant inner options and widely-varying characteristic sizes.”

The researchers be aware that HyFAM is especially helpful for mass customization situations the place objects have each detailed and non-detailed sections. Whereas not supreme for extremely intricate uniform objects, the workforce plans to develop the strategy’s capabilities by experimenting with totally different materials combos to broaden potential functions in industries from building to mushy robotics.

Supply: engineering.jhu.edu