The strategy checks battery photos to identify issues earlier than failure. Can this straightforward step change how we construct lithium batteries? Right here’s what the examine discovered.

A brand new algorithm developed on the College of California San Diego might assist researchers detect lithium battery failure earlier than it occurs utilizing simply current microscope photos. This methodology analyzes how uniformly lithium deposits type on battery electrodes, offering an early warning signal of quick circuits and battery degradation.

The software works with scanning electron microscopy (SEM), a extensively used imaging approach in battery labs. Researchers say it may possibly pace up the event of safer and longer-lasting lithium metallic batteries, which promise as much as twice the vitality density of at the moment’s lithium-ion batteries—doubtlessly doubling EV vary and increasing machine battery life.

On the coronary heart of the issue is how lithium kinds throughout charging. If it deposits erratically, sharp, needle-like dendrites can develop and pierce inside elements, resulting in quick circuits. Till now, scientists judged lithium uniformity visually from SEM photos, a subjective method that diversified between labs.

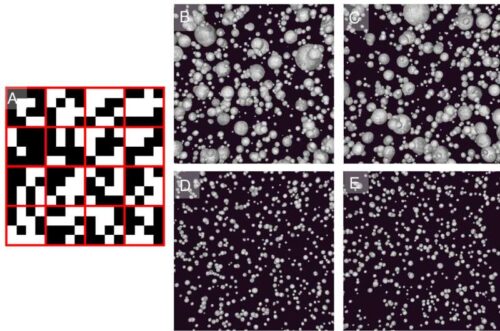

The algorithm brings consistency to this evaluation. It converts SEM photos into black-and-white pixels, representing lithium and substrate. Then, it divides the picture into small sections and counts the white pixels in every, calculating an “index of dispersion” (ID). A low ID alerts even lithium unfold. A excessive ID signifies clumping and threat.

The strategy was first validated on over 2,000 artificial SEM photos with recognized particle distributions. It then proved profitable when utilized to actual battery electrode photos. As batteries had been cycled repeatedly, the ID values rose, pointing to growing unevenness in lithium progress. This was accompanied by an increase within the vitality required for lithium deposition, each indicators of degradation. Notably, sudden ID spikes had been noticed simply earlier than failure, highlighting the metric’s potential as a predictive software.

What makes this method particularly impactful is its simplicity and compatibility. Since SEM is already customary in battery analysis, groups can apply the algorithm instantly to pictures they’ve already collected with no need new {hardware} or knowledge.

Lithium metallic batteries maintain big promise for vitality storage and electrical mobility, however uneven lithium progress stays a serious hurdle. With this new evaluation software, researchers could have a much-needed method to spot issues early, enhance designs quicker, and convey high-density batteries nearer to actuality.