Software program supplier Palantir Applied sciences and AI-driven 3D manufacturing options supplier, Divergent Applied sciences, have shaped a strategic partnership to combine Divergent’s superior manufacturing system with Palantir’s software program platforms. The collaboration allows customers of Palantir’s Warp Velocity and Foundry methods to entry Divergent’s on-demand elements, enhancing flexibility and accelerating manufacturing timelines.

Divergent defined that the combination offers Palantir’s protection and industrial prospects direct entry to its Adaptive Manufacturing System (DAPS), serving to them determine and deal with provide chain disruptions by way of fast, just-in-time manufacturing.

“By offering entry to Divergent’s subsequent era manufacturing immediately inside Palantir’s trade main software program our prospects can determine and resolve manufacturing shortages and new product developments on unmatched timelines,” stated Lukas Czinger, President & Chief Government Officer of Divergent. “This partnership facilities on successfully distributing excessive affect functionality. We’re bringing the ability of DAPS to Palantir’s world buyer base.”

Integrating Software program and Manufacturing for Scalable Innovation: Divergent and Palantir Be a part of Forces

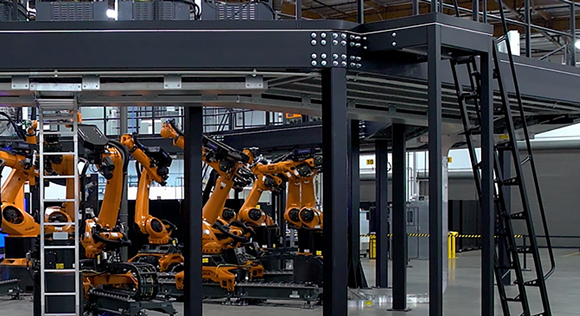

Divergent’s DAPS is a completely built-in engineering and manufacturing platform that mixes AI-driven design, industrial-scale additive manufacturing, and robotic meeting. The result’s a manufacturing system that delivers high-performance elements sooner and extra cost-effectively than conventional manufacturing strategies.

“Divergent is a trailblazer within the new industrial revolution that’s sweeping the US,” stated Shyam Sankar, Palantir CTO. “The Divergent Adaptive Manufacturing System is a mind-bending instance of what’s doable when the world’s most superior software program fuses with the world’s most superior manufacturing. We’re proud to assist Divergent’s progressive operations with Warp Velocity because it scales in ambition and affect.”

In the meantime, Palantir’s Warp Velocity platform acts as a contemporary manufacturing working system, delivering the pace, adaptability, and safety required in at the moment’s quickly evolving manufacturing panorama. Earlier this 12 months, Palantir expanded Warp Velocity’s adoption by way of a brand new cohort of companions centered on accelerating the onshoring of U.S. manufacturing.

Driving Provide Chain Effectivity by way of Digital Innovation

In 2020, Brazilian petrochemical firm Braskem adopted the DigiPart program from French 3D software program start-up Spare Components 3D (SP3D) to optimize its spare elements stock provide chain. Beforehand, Braskem accomplished a pilot venture utilizing DigiPart software program to investigate key metrics akin to half worth, Minimal Order Amount (MOQ), and lead instances throughout its stock. The analysis lined 15,000 elements, revealing that 47% had been surplus to operational necessities—highlighting important alternatives for stock discount and price financial savings.

In 2025, Würth Additive Group launched the complete version of its Digital Stock Companies (DIS) platform on the AMUG convention. This milestone marked the transition of DIS from a minimal viable product to a complete, absolutely operational system designed to assist digital half storage and distributed manufacturing at scale.

First unveiled at AMUG 2024, the DIS platform empowers authentic gear producers, suppliers, and repair suppliers to handle validated half recordsdata, oversee manufacturing workflows, and guarantee real-time half availability. Larry Stevens, Government Vice President of Würth Line Trade Asia-Pacific, Africa, and Americas, defined that Würth’s integration of additive manufacturing into its broader digital provide chain framework affords corporations progressive methods to supply, manage, and distribute elements globally. This method not solely helps environment friendly stock methods but additionally aligns with evolving operational calls for and sustainability targets.

Take the 3DPI Reader Survey — form the way forward for AM reporting in underneath 5 minutes.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to maintain up with the most recent 3D printing information.

You can too comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals DAPS in use throughout automobile meeting at Divergent Applied sciences’ facility. Picture through Divergent Applied sciences.