Steel 3D printer producer Nikon SLM Options has fashioned a strategic partnership with U.S.-based specialty supplies producer Allegheny Applied sciences Included (ATI) and engineering agency Bechtel Plant Equipment, Inc. (BPMI) to drive developments in hypersonic and naval propulsion applied sciences. As a part of this collaboration, ATI has acquired the NXG 600E metallic additive manufacturing system to spice up manufacturing capability for vital parts supporting U.S. Navy and Division of Protection packages at its manufacturing websites.

“The NXG 600E’s expansive construct quantity and complicated assist construction capabilities align seamlessly with U.S. Navy propulsion necessities,” expressed Nathan Weiderspahn, BPMI Government Supervisor, Industrial Base Administration. “Nikon SLM Options’ cutting-edge additive manufacturing know-how is ready to play a pivotal function in advancing the U.S. Navy’s operational readiness, contributing to the upkeep and enhancement of our nation’s fleet.”

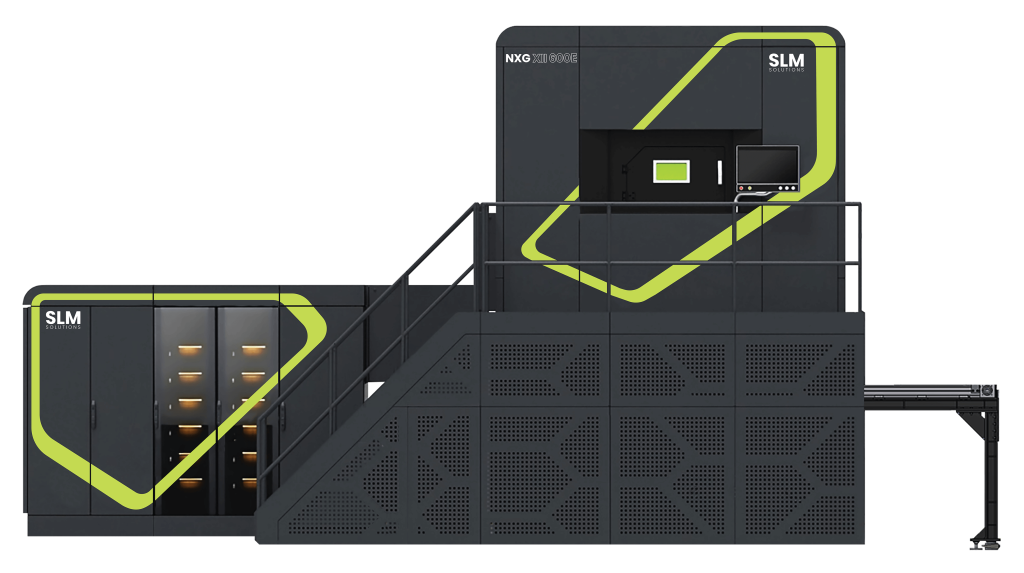

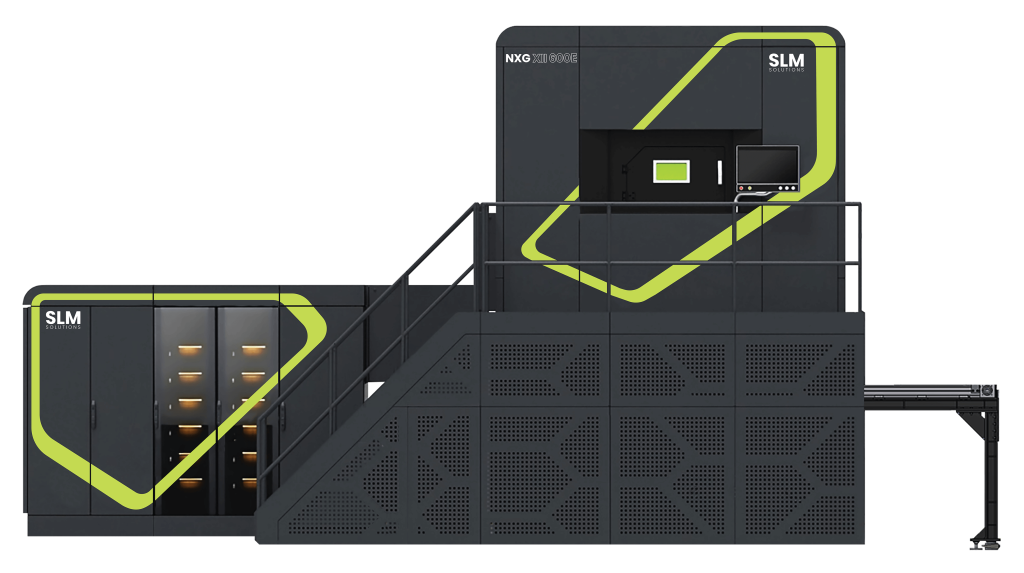

Increasing Protection Manufacturing with the NXG 600E

As a part of this partnership, ATI has bought the NXG 600E metallic additive manufacturing system. The system was chosen to deal with the technical necessities of U.S. Navy propulsion and hypersonic weapon parts. With its 1.5-meter Z-axis and excessive manufacturing capability, the NXG 600E is meant to assist ATI’s manufacturing capabilities in protection purposes.

ATI plans to make the most of Inconel 625 with the NXG 600E, a high-performance alloy extensively utilized in hypersonic and naval propulsion programs, in addition to numerous demanding industrial purposes. The June supply of the NXG 600E is predicted to boost ATI’s metallic additive manufacturing capabilities, leveraging their confirmed success with the SLM125 and experience in Nikon SLM’s open machine structure and superior parameter growth.

“Within the dynamic panorama of additive manufacturing, Nikon SLM Options is taking a big leap ahead,” stated Sam O’Leary, CEO. ” This strategic growth underscores our dedication to delivering American-made ingenuity, superior know-how, and empowering the protection and aerospace sectors with cutting-edge additive manufacturing capabilities,” stated Sam O’Leary, CEO of Nikon SLM Options.

Industrial Adoption of the NXG XII 600E

Launched in 2022, the NXG XII 600E by SLM Options is a metallic additive manufacturing system with a construct quantity of 600 × 600 × 1,500 mm enabled by a 1.5-meter Z-axis. Geared up with twelve 1,000-watt lasers, the NXG delivers quick and correct melting of metallic powder, enabling the manufacturing of high-quality, uniform elements. The system is designed to deal with massive, complicated parts in a single construct and helps industrial-scale manufacturing with options geared toward enhancing pace and course of management. It consists of workflow enhancements meant to maximise machine uptime and scale back manufacturing cycle instances.

Among the many current adopters of the NXG XII 600 know-how is German multinational engineering and know-how firm Bosch launched a brand new metallic additive manufacturing facility at its Nuremberg plant, investing practically €6 million. On the coronary heart of the ability is a Nikon SLM Options NXG XII 600 metallic 3D printer, which the corporate says will play a key function in producing complicated metallic elements extra effectively. With this addition, the automotive large sees itself as the primary Tier-1 automotive provider in Europe to function a facility on this efficiency class.

Elsewhere, semiconductor manufacturing firm Veeco began utilizing Nikon SLM Options’ NXG XII 600 metallic AM system to advance its manufacturing processes. Designed for creating intricate parts reminiscent of gasoline supply programs and warmth exchangers, the know-how enhances precision and effectivity in semiconductor manufacturing. Having built-in additive manufacturing into its operations, Veeco goals to boost productiveness and speed up time-to-market.

Take the 3DPI Reader Survey — form the way forward for AM reporting in beneath 5 minutes.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to maintain up with the most recent 3D printing information.

You may as well observe us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals Nikon 3D Printing. Picture by way of Nikon.