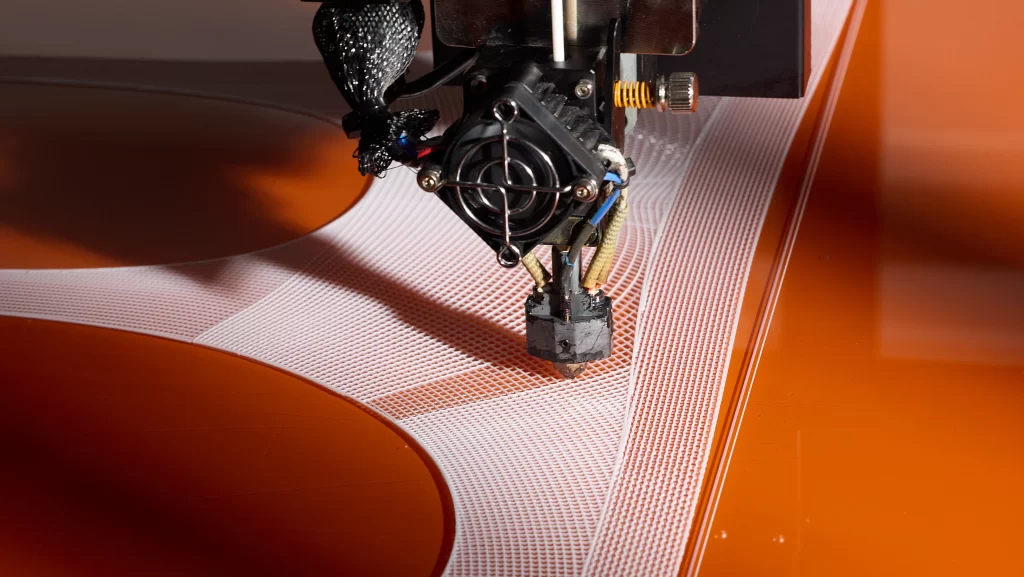

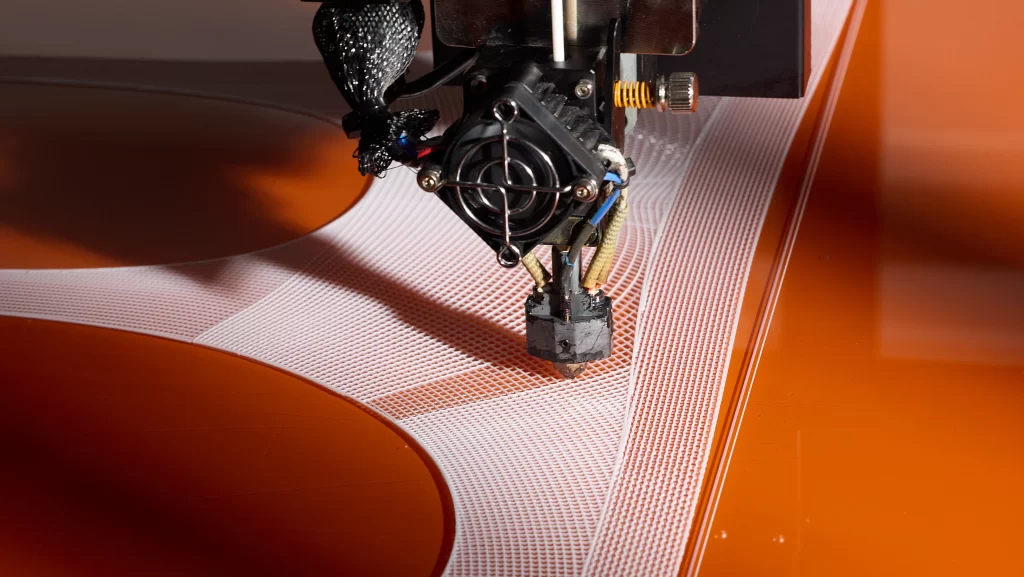

Nike, the U.S.-based athletic put on firm, has developed a 3D printed sports activities bra utilizing a brand new materials referred to as FlyWeb. The garment is ready to debut on June 26 throughout middle-distance runner Religion Kipyegon’s try to interrupt the 4-minute mile barrier in Paris. The product is Nike’s first utility of additive manufacturing in efficiency attire.

FlyWeb is made out of thermoplastic polyurethane (TPU), a tender and pliable polymer, and is fabricated by way of 3D printing slightly than conventional knitting or weaving. The fabric kinds a single, seamless layer tailor-made utilizing computational design. Designers adjusted properties akin to stretch, airflow, and help by modulating density throughout completely different zones of the garment. “It took years of re-engineering — not simply the supplies however the design strategy itself — to make FlyWeb really feel tender, breathable and exquisite sufficient for attire,” mentioned Janett Nichol, Nike’s Vice President of Innovation.

Improvement centered on the sports activities bra, a product that has remained largely unchanged when it comes to materials building. The printed design removes the multi-layer barrier typical of typical sports activities bras, permitting for extra airflow and decreasing trapped moisture. Assist comes from construction slightly than compression or padding, with denser areas printed the place containment is required. Based on Nichol, put on testers persistently mentioned it felt as if they weren’t carrying something in any respect: “That’s the No. 1 factor testers inform us: It disappears in your physique but by some means delivers unbelievable help.”

The choice to speed up FlyWeb’s improvement got here in parallel with Kipyegon’s “Breaking4” effort. Nike’s design crew labored to maneuver the fabric from prototype to product in anticipation of the occasion. “Everybody was a thought associate; we actually put our heads collectively,” mentioned Lisa Gibson, Senior Product Supervisor in Attire Innovation. “And when you’ve got a crew working in synergy, believing in Religion and this second, that’s when issues begin to magically unlock.”

FlyWeb strikes responsively with the physique with out the necessity for seams, straps, or extra materials. Nichol famous that some wearers reported with the ability to really feel airflow on the chest for the primary time whereas operating, a sensation made doable by the garment’s open, breathable zones. “Most ladies have by no means skilled that whereas operating,” she mentioned. “We don’t even give it some thought as a result of it’s simply not one thing we’ve ever anticipated to really feel.”

Nike has beforehand used 3D printing in footwear, however FlyWeb marks the corporate’s entry into 3D printed efficiency clothes. The debut additionally displays ongoing efforts inside the business to discover additive manufacturing for next-to-skin purposes. Whereas no extra FlyWeb merchandise have been introduced, Nike has indicated that the challenge is ongoing. “It is a true unlock, not only for bras however for the way we design and construct high-performance attire going ahead,” mentioned Nichol. “It opens the door to thoroughly new concepts for the way athletes expertise sport by way of what they put on.”

Direct-to-garment and textile purposes of 3D printing

3D printing has steadily expanded into the style sector over the previous a number of years, pushed by improvements in direct-to-garment applied sciences and on-demand customization. In February, the New York Embroidery Studio (NYES), a design agency recognized for work on occasions just like the MET Gala, built-in Stratasys’s J850 TechStyle printer into its operations. The system permits full-color 3D printing immediately onto materials, enabling exact tactile gildings and decreased materials waste. A yr later, Stratasys prolonged these capabilities with a Direct-to-Garment (D2G) characteristic supporting a variety of textiles, together with denim and polyester. NYES cited the know-how as central to its manufacturing workflow and sustainability objectives, providing new potentialities for high-end and industrial trend use instances.

Unbiased manufacturers have additionally adopted 3D printing to bypass conventional constraints in garment manufacturing. On the WINGS 2025 Unbiased Trend Pageant, Australian label Amiss introduced a debut assortment produced utilizing Creality’s fabrication instruments. The designers used the Otter Lite 3D scanner to seize natural textures from pure environments, then printed corsets, equipment, and structural clothes in-house with the K2 Plus 3D printer. Prototypes that beforehand took weeks had been accomplished in beneath two hours. Further parts had been produced utilizing the Falcon2 Professional 60W laser cutter to create customized textiles and shapes. Co-founders Vanessa and Josh reported that this strategy decreased prices, accelerated improvement, and eradicated the necessity for exterior manufacturing.

AMAA 2025 is right here. One occasion. Numerous insights. Safe your house now.

Prepared to find who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.

Featured picture reveals a close-up of the 3D printing course of used to fabricate Nike’s FlyWeb material. Photograph by way of Nike.