Researchers from Melbourne’s RMIT College have developed a brand new titanium alloy that’s almost one-third cheaper to 3D print than customary Ti-6Al-4V.

The workforce outlined their methodology in a latest Nature Communications examine titled “Compositional standards to foretell columnar to equiaxed transitions in steel additive manufacturing.”

This paper presents a time- and cost-effective strategy to deciding on alloying components, aimed toward optimizing steel additive manufacturing. It gives a framework for predicting the grain construction of 3D printed metallic alloys, permitting engineers to attain efficiency enhancements and value financial savings.

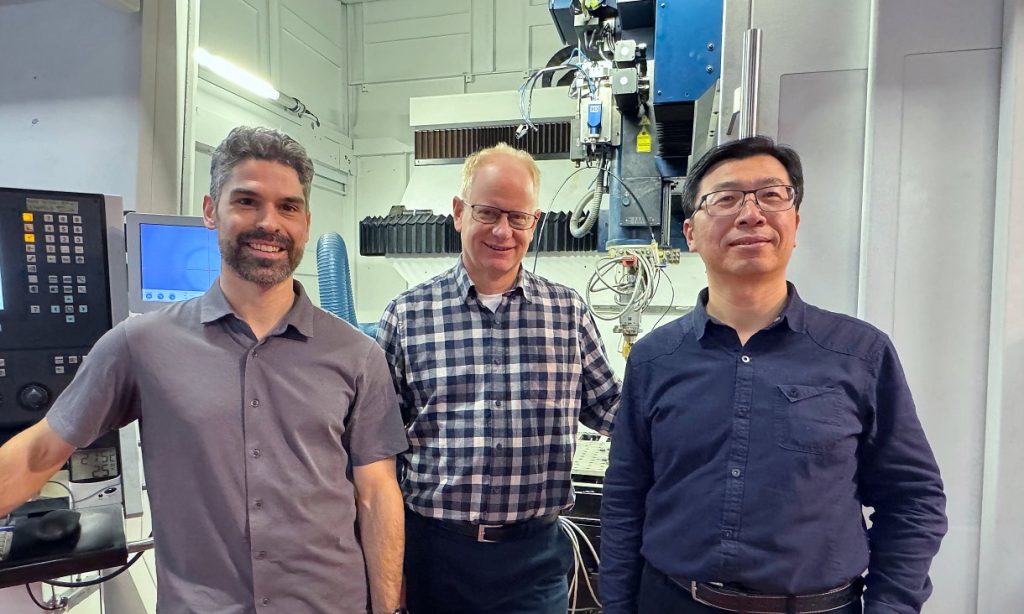

Ryan Brooke, a PhD candidate at RMIT’s Centre for Additive Manufacturing (RCAM), led the initiative alongside Professor Mark Easton and Dr Dong Qiu. Brooke’s workforce is now exploring alternatives to commercialize its new steel 3D printing strategy for aerospace and medical machine functions.

RMIT’s novel alloy was not introduced within the analysis paper for industrial causes. It’s reportedly 29% cheaper to 3D print than customary titanium. The brand new design framework additionally allows extra even 3D printing and stronger remaining components that possess enhanced ductility, in keeping with the researchers.

“3D printing permits sooner, much less wasteful and extra tailorable manufacturing but we’re nonetheless counting on legacy alloys like Ti-6Al-4V that doesn’t permit full capitalisation of this potential,” Brooke defined.

“New varieties of titanium and different alloys will permit us to actually push the boundaries of what’s potential with 3D printing and the framework for designing new alloys outlined in our examine is a major step in that course.”

RMIT to commercialize new, low-cost titanium alloy

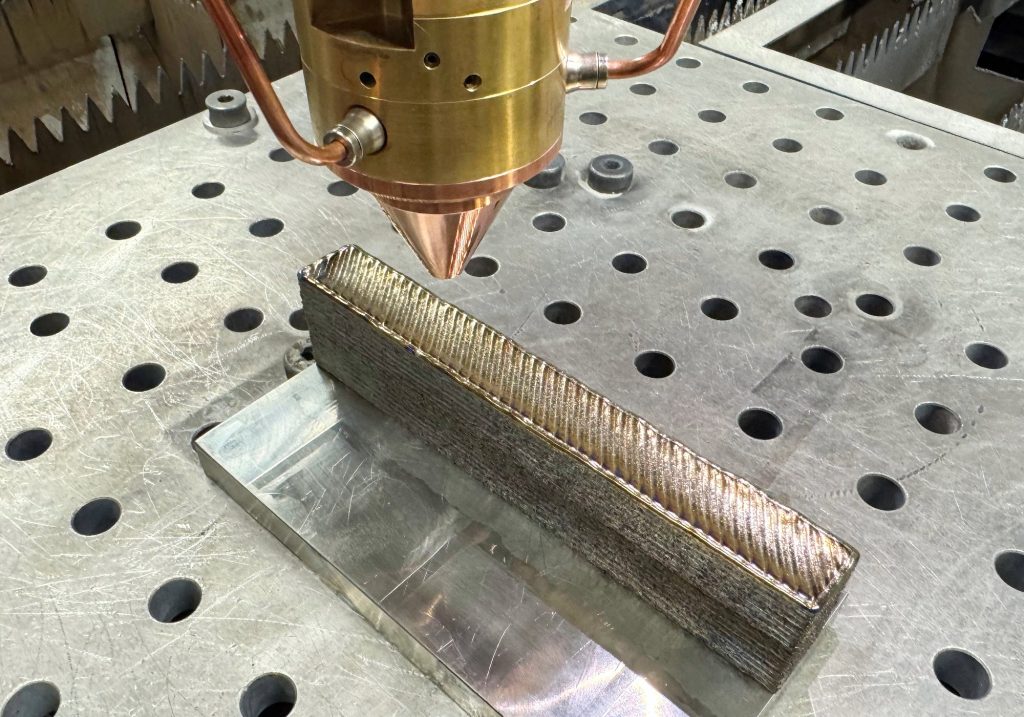

Brooke’s engineering workforce used their design framework to develop and 3D print samples of their new alloy at RMIT’s Superior Manufacturing Precinct in Carlton, Victoria. They produced the components utilizing laser beam directed vitality deposition (DED-LB).

Along with value financial savings, the method prevented the formation of column-shaped microstructures, flaws that may trigger uneven mechanical properties in some 3D printed alloys.

Brooke has since accepted a Analysis Transformation Fellowship at RMIT to research the subsequent steps for commercialization. RMIT has additionally filed a provisional patent to guard its design framework.

“By growing a more cost effective method that avoids this columnar microstructure, we now have solved two key challenges stopping widespread adoption of 3D printing,” commented Brooke.

The examine’s lead creator, who holds a Grasp’s diploma in Manufacturing Engineering, has carried out market validation by way of the Commonwealth Scientific and Industrial Analysis Organisation (CSIRO)’s ON Prime program. Through the nine-week course, Brooke spoke with trade representatives throughout the aerospace, automotive, and MedTech industries to higher perceive their wants.

“What I heard loud and clear from finish customers was that to convey new alloys to market, the advantages need to not simply be minor incremental steps however a full leap ahead, and that’s what we now have achieved right here,” Brooke mentioned. “We’ve got been capable of not solely produce titanium alloys with a uniform grain construction, however with diminished prices, whereas additionally making it stronger and extra ductile.”

Trying forward, RMIT’s RCAM is actively pursuing new collaborations to advance the expertise.

Professor Easton, Affiliate Deputy Vice Chancellor (Analysis Infrastructure), emphasised that the brand new alloy “requires a workforce from throughout the provision chain to make it profitable.” He added that RCAM is in search of new companions “to offer steerage for the subsequent phases of growth.”

Researchers advance steel 3D printing

RMIT shouldn’t be the one college working to enhance steel additive manufacturing methods. Earlier this yr, a workforce from the College of Toronto developed a machine-learning-powered framework to speed up and refine laser-based steel 3D printing.

The researchers’ system, known as AIDED, permits customers to foretell and inversely decide optimum 3D printing parameters for DED-LB. This strategy reportedly considerably reduces the time and experimentation wanted to attain high-quality outcomes.

AIDED employs two educated machine studying fashions and a genetic algorithm to generate the perfect course of parameters based mostly on user-defined efficiency objectives, comparable to print velocity and soften pool geometry. In line with the examine, revealed in Additive Manufacturing, the framework achieved an R² rating of 0.995 for predicting single-track soften pool areas. It additionally notched 0.969 for the lean angle of multi-track soften swimming pools, indicating spectacular accuracy.

In different information, researchers from Cranfield College confirmed that controlling interpass temperature (IPT) in Chilly Wire Gasoline Metallic Arc (CW-GMA) welding can improve 3D printing productiveness with out sacrificing the mechanical efficiency of tremendous duplex chrome steel (SDSS) components.

Revealed within the Journal of Manufacturing Processes, the examine evaluated the consequences of three interpass temperature (IPT) settings (75 °C, 200 °C, and 350 °C) on the microstructure and properties of tremendous duplex chrome steel (SDSS) throughout wire directed vitality deposition. The researchers noticed notable variations in thermal accumulation and grain coarsening, but discovered minimal impression on section stability or tensile energy.

Who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

It’s also possible to observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals PhD candidate and examine lead creator Ryan Brooke inspecting a pattern of the brand new titanium. Photograph through Michael Quin, RMIT College.