French researchers have developed a brand new optimization framework for 3D printed concrete that reduces materials utilization by as much as 25% whereas sustaining structural integrity. The examine, printed in Automation in Building and led by Dr. Romain Mesnil at École des Ponts ParisTech, focuses on variable layer thickness achieved by adjusting robotic velocity throughout printing. The strategy marks a departure from typical 3D concrete printing strategies that sometimes use uniform wall thickness.

“This analysis exhibits that by leveraging the capabilities of robotic printing, we are able to transfer past fixed layer designs and make data-driven selections about the place materials is really wanted,” mentioned Dr. Mesnil. “It’s a step-change towards greener, smarter development.”

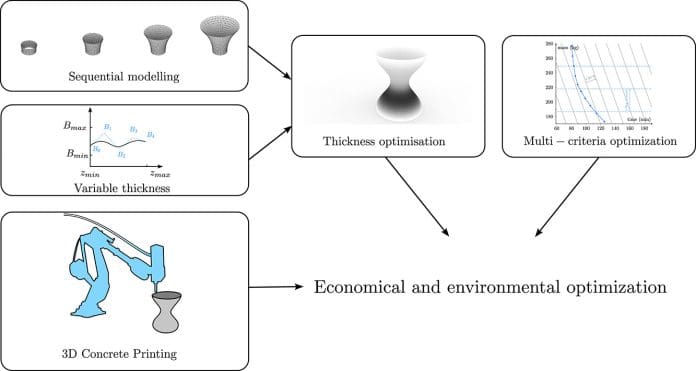

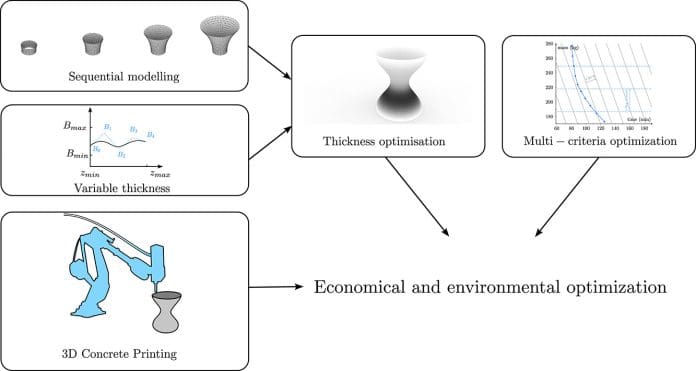

The crew’s methodology employs a light-weight finite ingredient evaluation strategy utilizing shell parts, which reduces computation time whereas sustaining accuracy. Their framework features a parametric optimization routine connecting course of parameters with materials deposition, Bezier splines to regulate thickness gradients, and built-in numerical evaluation to make sure mechanical reliability. The researchers validated their strategy by full-scale printing experiments on advanced shapes utilizing a robotic arm system from XTreeE.

Testing confirmed variable thickness printing achieved as much as 25% discount in concrete utilization and 20% lower in price in comparison with typical strategies. An hourglass-shaped take a look at construction demonstrated significantly sturdy outcomes, with variable thickness designs outperforming fixed thickness in materials effectivity, time, and value metrics.

The optimization framework provides producers potential advantages together with lowered carbon emissions, sooner print instances, and suppleness in balancing productiveness with environmental efficiency. To facilitate adoption, the researchers developed a design-to-print workflow appropriate with widespread parametric design software program Grasshopper and Karamba, permitting for integration into current design environments.

Supply: pbctoday.co.uk