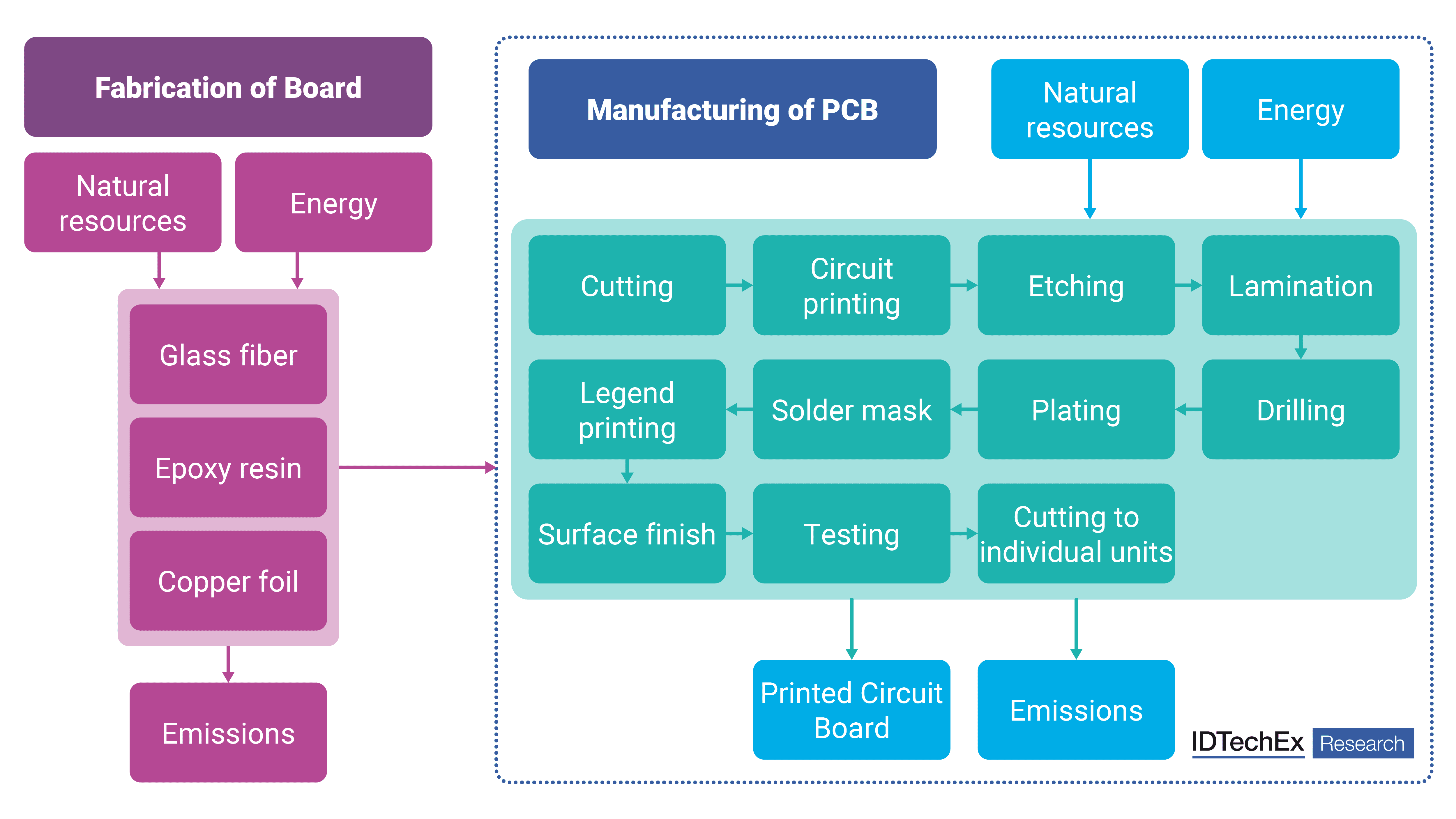

Standard printed circuit board (PCB) manufacturing is wasteful, dangerous to the surroundings and vitality intensive. This may be mitigated by the implementation of recent recyclable supplies and applied sciences, which have the potential to revolutionize electronics manufacturing, explains Thomas Bithell of market intelligence agency IDTechEx, in a brand new report.

Throughout analysis interviews for the report “Sustainable Electronics and Semiconductor Manufacturing 2025-2035: Gamers, Markets, Forecasts”, IDTechEx discovered that current analysis and testing developments have resulted in lots of of those supplies approaching full-scale industrial readiness, while price and efficiency stay a barrier for a lot of others.

New substrates

FR4 stays the dominant substrate of alternative for PCBs, a glass-reinforced epoxy resin laminate. It’s light-weight, robust, and low-cost. Nevertheless, additionally it is non-recyclable and might include poisonous halogenated flame retardants, which could be launched into the ambiance at end-of-life by way of incineration. This makes various substrates fascinating, which could possibly be bio-based, biodegradable or recyclable.

One promising new materials is JIVA’s Soluboard®, a biodegradable substrate produced from the pure fibers flax and jute. It dissolves in 90°C water, permitting part recycling and treasured steel restoration at finish of life. The substrate is at the moment being examined by firms comparable to Microsoft, Infineon, and Jaguar, who additionally see it as a technique to fight rising world e-waste ranges.

Polylactic acid is one other sustainable materials with alternatives in versatile PCBs. The chemical could be sourced from natural industrial waste and can also be biodegradable. Standard versatile PCBs are produced from the plastic polyimide, with sustainably sourced alternate options but to be discovered. Polylactic acid could possibly be the answer, at the moment within the protype scale validation section, demonstrated by firms and analysis institutes comparable to VTT. It may well stand up to temperatures of as much as 140°C, which is decrease than that of polyimide and FR4, however is suitable with manufacturing processes comparable to silver ink sintering.

Sustainable soldering

Mayerhofer Electronik was the primary to show using second-life tin for soldering in its electronics manufacturing processes. 180,000 tonnes of main tin are utilized in electronics globally, primarily sourced from mines in China, Indonesia and Myanmar, inflicting vital environmental injury. The standard of recycled tin is similar as main tin, confirmed by X-ray diffraction. It’s produced by smelting waste steel and steel oxide. Solely round 30% of tin is at the moment recycled worldwide so there may be big potential for a push in the direction of a round economic system in soldering processes.

Sturdy regulatory drivers are anticipated to encourage elevated steel recycling, with secondary copper one other with the potential for implementation into electronics. The strongest regulation thus far is seen in Germany. Their Nationwide Round Economic system Technique (NKWS) unveiled in 2024 goals to half per capita uncooked materials consumption by 2045. It additionally goals to double the share of recycled supplies throughout all industries and cut back municipal waste by 10%. Apple have dedicated to utilizing secondary tin in all merchandise by 2035. There may be scope for extra firms to observe go well with and even implement secondary tin sooner.

Recovering copper waste and chemical etchants

Copper is used wastefully in PCBs. A flat sheet of copper is utilized to the substrate, earlier than holes are drilled and a circuit sample produced by etching away the surplus copper, which requires massive volumes of chemical etchants comparable to ferric (III) chloride and cupric (II) chloride. Round 70% of the copper initially utilized to the board is commonly eliminated.

A method of eradicating this waste of copper is to make use of additive manufacturing, by which copper is just utilized the place it’s required. Adoption of those strategies has been restricted as a result of capital prices of switching manufacturing strategies. A technique that requires no manufacturing swap is to make use of etchant regeneration programs, which get better each copper that has been etched from the laminate, and etchant chemical substances. This recycled copper can then function a further income stream to the electronics producer. These regeneration programs have been commercially accessible for over a decade and have been discovered to have a payback interval of roughly 6 to 18 months. Programs can be found utilizing chlorine fuel as an oxidizing agent or using electrolysis. The latter has a bigger vitality requirement. Each can lengthen the lifetime of etchants. For ferric (III) chloride the lifetime is roughly tripled, and hydrochloric acid consumption could be decreased by round 95%.

Elevated recycling has the potential to considerably cut back materials waste from electronics recycling, in addition to probably decreasing vitality necessities by way of much less materials manufacturing required. Recyclable and biodegradable supplies additionally are typically much less dangerous to the surroundings than a few of the conventionally used supplies. Nevertheless, rising using recyclable supplies is only one means the sustainability of electronics manufacturing could be improved.

IDTechEx’s report “Sustainable Electronics and Semiconductor Manufacturing 2025-2035: Gamers, Markets, Forecasts” gives evaluation of extra sustainable electronics manufacturing strategies, in each the PCB and semiconductor manufacturing worth chain. For extra data go to www.IDTechEx.com/SustainableElectronics.