By combining magnetic sensing and digital processing, the encoder converts the machine’s rotation into exact place knowledge.

As robots and motor-driven methods change into extra complicated, exact and dependable place sensing has change into important. Trendy automation and robotics require encoders that may ship correct suggestions, tolerate set up variations, and face up to mud, vibration, and magnetic interference.

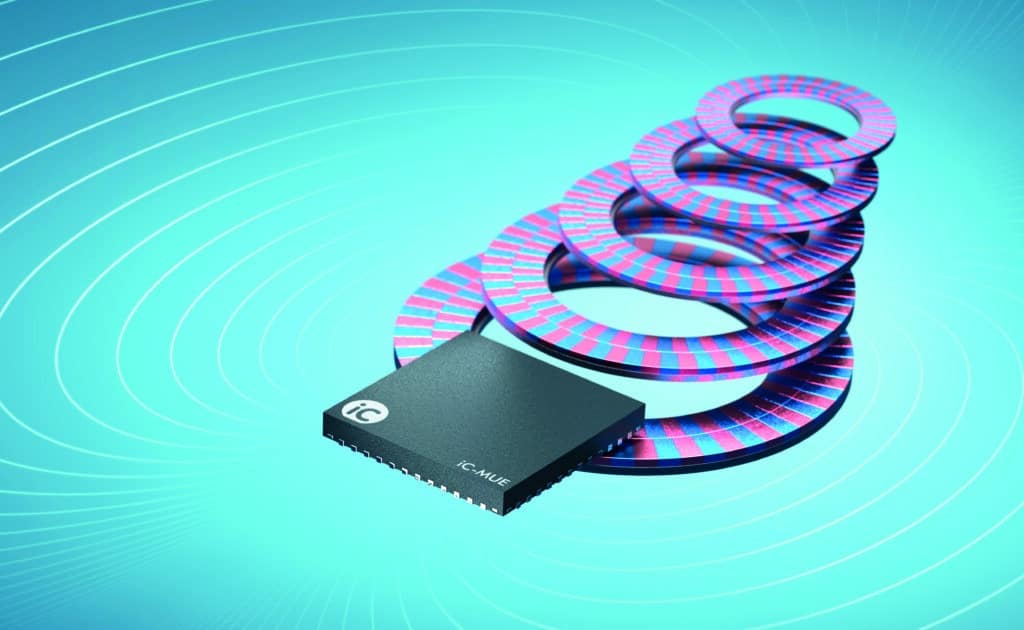

To fulfill these wants, iC-Haus introduces the iC-MUE (Magnetic Hollowshaft Encoder), a Magnetic system-on-chip encoder designed particularly for hole shaft purposes.

The chip is a system-on-chip (SoC) system, which suggests all the important thing sensing and processing capabilities are constructed into one small IC. It detects the place of a rotating magnetic area and converts it into digital or analogue alerts that management a machine’s motion. This makes it helpful for robotic arms, motor drives, and automation methods that require correct suggestions.

The design is predicated on the corporate’s earlier iC-MU collection however provides higher flexibility and efficiency. Utilizing a decimal Nonius precept, the chip can adapt to totally different magnetic scale sizes, from 20 mm to 85 mm in diameter. It could possibly measure rotation angles with a decision of 21 bits and accuracy of about 0.04 levels for a 44 mm magnetic scale.

To make set up simpler, the chip contains built-in calibration. Customers can modify settings by means of software program or on the press of a button. It additionally corrects alignment errors mechanically and filters out magnetic noise utilizing differential magnetic scanning, which improves reliability in industrial environments.

The chip helps a number of communication interfaces akin to BiSS, SSI, SPI, ABZ, UVW, and analogue outputs, so it might connect with totally different management methods. It additionally has an I²C interface for configuration and diagnostics, and might be linked to an exterior multiturn sensor for prolonged place monitoring.

Working on 3.3 to five volts and throughout -40°C to 125°C, it features a temperature sensor, safety-ready analogue output, and built-in diagnostics. These options make the chip appropriate for manufacturing facility automation, motor suggestions methods, and robotic purposes the place compact, exact, and dependable movement sensing is crucial.