This new microchip course of with exact supplies and lasers permits making circuits smaller and extra environment friendly.

Whereas chips are being constructed at 3nm or smaller, not all chip parts require excessive miniaturisation. Many interconnect layers, reminiscence buildings, or RF parts nonetheless use options within the 100–250nm vary. It permits low-cost, scalable lithography for IoT MCUs, MEMS, or analog-digital combined sign chips.

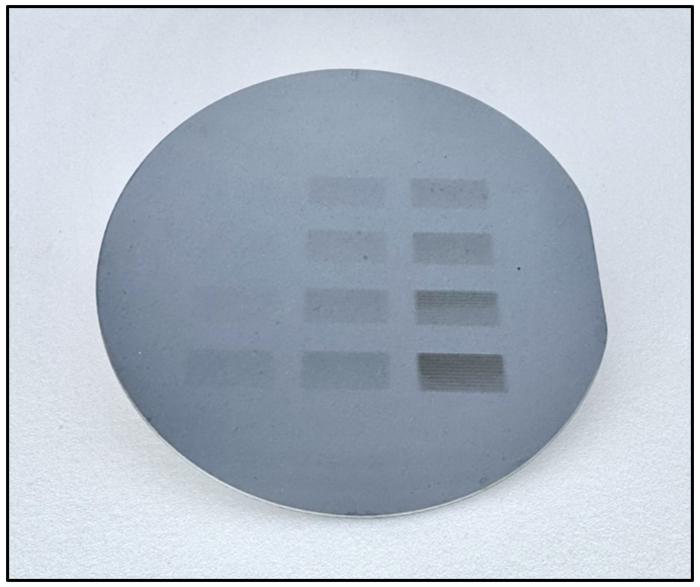

Johns Hopkins College researchers have launched a fabrication course of that allows circuit patterning on microchips at a precision of 229 nanometres. The tactic combines solution-based deposition strategies with new metal-organic resist supplies, designed to operate underneath next-generation laser lithography techniques.

The method permits circuits to be written on silicon wafers utilizing a way that depends on radiation-triggered reactions inside a resist layer. This Resist layer above the silicon wafer is engineered from imidazole-based metal-organic compounds and responds to past excessive ultraviolet (B-EUV) radiation. B-EUV is a higher-energy successor to present EUV know-how and is predicted to be built-in into semiconductor manufacturing over the following decade.

Conventional Resists utilized in excessive ultraviolet lithography degrade underneath the extraordinary power ranges required for such fine-scale patterning. In distinction, the resists developed by the Johns Hopkins crew are designed to soak up B-EUV radiation extra effectively, significantly when paired with metals like zinc. When irradiated, these metals emit electrons that provoke chemical modifications within the imidazole, the resist layer on silicon wafer forming exact circuit patterns.

The resist materials is deposited by way of chemical liquid deposition (CLD), permitting engineers to tune thickness with nanometre accuracy. This management is important for chip producers aiming to extend transistor density whereas sustaining manufacturability and value effectivity.

By enabling scalable, high-resolution lithography with adaptable materials chemistry, the strategy addresses a key bottleneck in subwavelength chip fabrication.