A brand new testing centre at College of Glasgow is simulating the situations of outer house to assist forestall 3D printed elements from changing into sources of high-speed orbital particles.

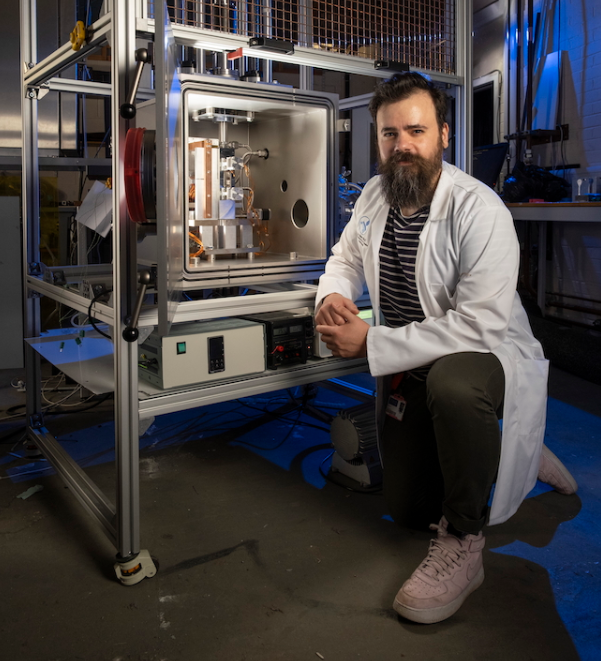

Housed on the college’s James Watt Faculty of Engineering, the NextSpace Testrig lab is designed to evaluate whether or not supplies like metals, polymers and ceramics can survive excessive house environments when printed aboard satellites or house stations.

The power was developed by Dr. Gilles Bailet in partnership with the Manufacturing Know-how Centre (MTC) and funded by the UK Area Company (UKSA), which contributed £253,000 by its Enabling Know-how Programme.

“3D printing is a really promising know-how for permitting us to construct very advanced buildings instantly in orbit as a substitute of taking them into house on rockets. It may allow us to create all kinds of units, from light-weight communications antennas to photo voltaic reflectors to structural elements of spacecraft and even human habitats for missions to the Moon and past,” defined Dr. Bailet.

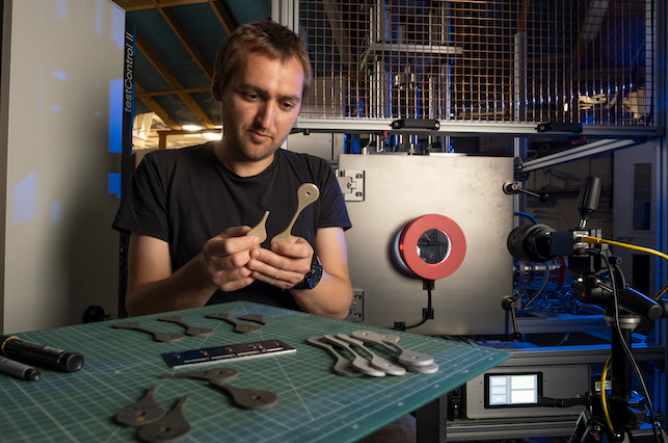

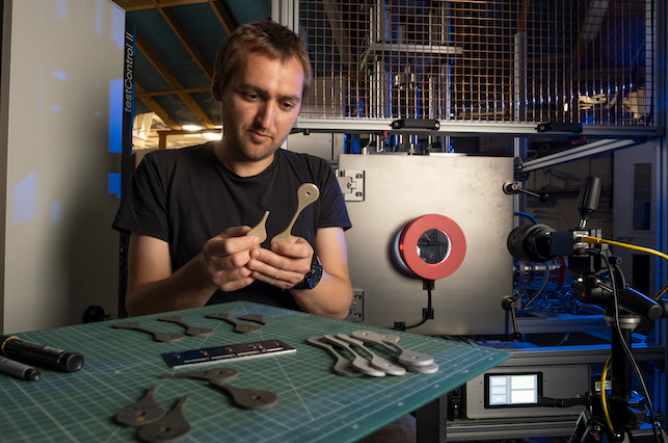

Testing printed supplies underneath stress

As nations and personal corporations are working to print spacecraft parts instantly in house, researchers warn that even microscopic flaws in printed supplies may pose critical dangers. Below excessive temperatures and vacuum situations, defects may trigger printed elements to crack or shatter, sending fragments hurtling by orbit at hundreds of kilometres per hour.

That particles would add to the rising cloud of house junk threatening satellites and house missions.

To deal with this, the brand new facility reproduces space-like situations utilizing a vacuum chamber that cycles between minus 150°C and plus 250°C. Inside, samples are subjected to intense stress, as much as 20 kilonewtons, to check their resilience. A rotating journal system permits a number of samples to be examined in a single run.

In accordance with the crew, no different facility on the planet at present affords this mixture of environmental and mechanical testing for space-printed supplies. Till now, 3D printers despatched to orbit have operated underneath experimental situations.

In doing so, astronauts have 3D printed elements aboard the Worldwide Area Station (ISS), main the first steel 3D printed half in house being despatched again on earth for testing not too long ago. Though, little is thought about how such objects would carry out over time underneath thermal and structural stress.

Earlier than the NextSpace Testrig, the college additionally developed a patented 3D printing system for low-gravity environments, efficiently examined throughout European Area Company (ESA) parabolic flights utilizing granular feedstock.

Led by Dr. Bailet and supported by UKSA and Glasgow Data Alternate Fund amongst others, the know-how goals to allow on-demand house fabrication of buildings and electronics, doubtlessly enhancing solar energy assortment and pharmaceutical manufacturing in orbit, whereas decreasing reliance on Earth-based payload launches and mitigating house particles dangers.

“The NextSpace TestRig is open to tutorial colleagues, researchers and industrial shoppers from world wide,” stated Dr. Bailet. The Glasgow crew hopes its work will information future rules for in-space manufacturing and cut back the dangers posed by fragile or flawed parts.

Printing tech and tissue in house

Area manufacturing has an enormous potential by utilizing 3D printers to construct elements in orbit, quite than launching them totally assembled from Earth.

Constructing on this, In-space manufacturing deep-tech startup Orbital Composites has been awarded a $1.7 million SBIR contract by the U.S. Area Drive’s SpaceWERX Orbital Prime program, funded by the Air Drive Analysis Laboratory (AFRL).

Partnering with Axiom Area, Northrop Grumman, and the Southwest Analysis Institute (SwRI), the corporate is working to advance antenna methods for In-space Servicing, Meeting, and Manufacturing (ISAM). The initiative focuses on constructing antennas instantly in orbit to help satellite-based mobile broadband and space-based solar energy, with the objective of decreasing prices and increasing industrial functions.

On the medical entrance, house system producer Redwire efficiently bioprinted a human knee meniscus aboard the ISS utilizing its upgraded BioFabrication Facility. The tissue was cultured for 14 days in microgravity and returned to Earth with SpaceX’s Crew-6 Mission for evaluation after printing in September 2023.

Performed with the Uniformed Companies College and NASA astronauts, this improvement aimed to enhance remedy for meniscal accidents frequent amongst U.S. service members. The upgraded system enabled exact printing of bioink layers and long-term tissue culturing, with future functions concentrating on organ donor shortages and regenerative drugs.

Take the 3DPI Reader Survey — form the way forward for AM reporting in underneath 5 minutes.

What 3D printing tendencies must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals Dr. Gilles Bailet with the NextSpace TestRig. Photograph by way of College of Glasgow.