Shenzhen Tuozhu Know-how Co., Ltd., the father or mother firm of Chinese language 3D printer producer Bambu Lab, has patented a brand new 3D printer heatbed design.

Titled “Heated Mattress of 3D Printer, and 3D Printer,” the patent was revealed internationally below the Patent Cooperation Treaty (PCT), a world treaty administered by the World Mental Property Group (WIPO), on Might 8, 2025.

It’s designed to boost 3D printer efficiency and accessibility. Options embrace built-in heating parts, a redesigned magnet structure, aluminum-free building, mattress stage adjustability, and security measures. These reportedly scale back prices with out sacrificing efficiency.

Implications for Stratasys v. Bambu Lab?

This patent (WO2025/092408) has been revealed amid Bambu Lab’s authorized battle with Stratasys. The economic 3D printer OEM alleges that Bambu Lab’s X1C, X1E, P1S, P1P, A1, and A1 mini 3D printers infringe on ten of its patents.

One such patent, US patent No. 9,592,660, covers a heated construct platform utilized in 3D printing. This was filed by steady carbon fiber 3D printer developer Arevo, Inc. in 2014, and granted in March 2017. Silicon Valley-based Arevo ceased operations in 2023. Stratays acquired its mental property in March 2024.

The important thing distinction between Stratasys’s U.S. Patent No. 9,592,660 and Bambu Lab’s WO2025/092408 lies of their structural configurations.

Stratasys’s patent focuses on a heated construct platform with a skinny, detachable plate coated with a high-temperature polymer, designed to forestall warping and facilitate simple removing of printed objects.

In distinction, Bambu Lab’s patent describes a heated mattress the place the heating unit is built-in between the heated mattress physique and the underside shell, optimized for adhesion, 3D print high quality, and affordability. This new patent could possibly be used to strengthen Shenzhen Tuozhu Know-how Co., Ltd.’s authorized place as a co-defendant in Stratasys v. Bambu Lab.

The defendants may argue that the brand new design doesn’t infringe on Stratasys’s current patent, citing structural and purposeful variations between the 2. This may occasionally serve to spotlight Bambu Lab’s proprietary know-how, strengthen its market place, or present leverage in negotiations or a possible countersuit.

New Bambu Lab patent for a 3D printer heatbed

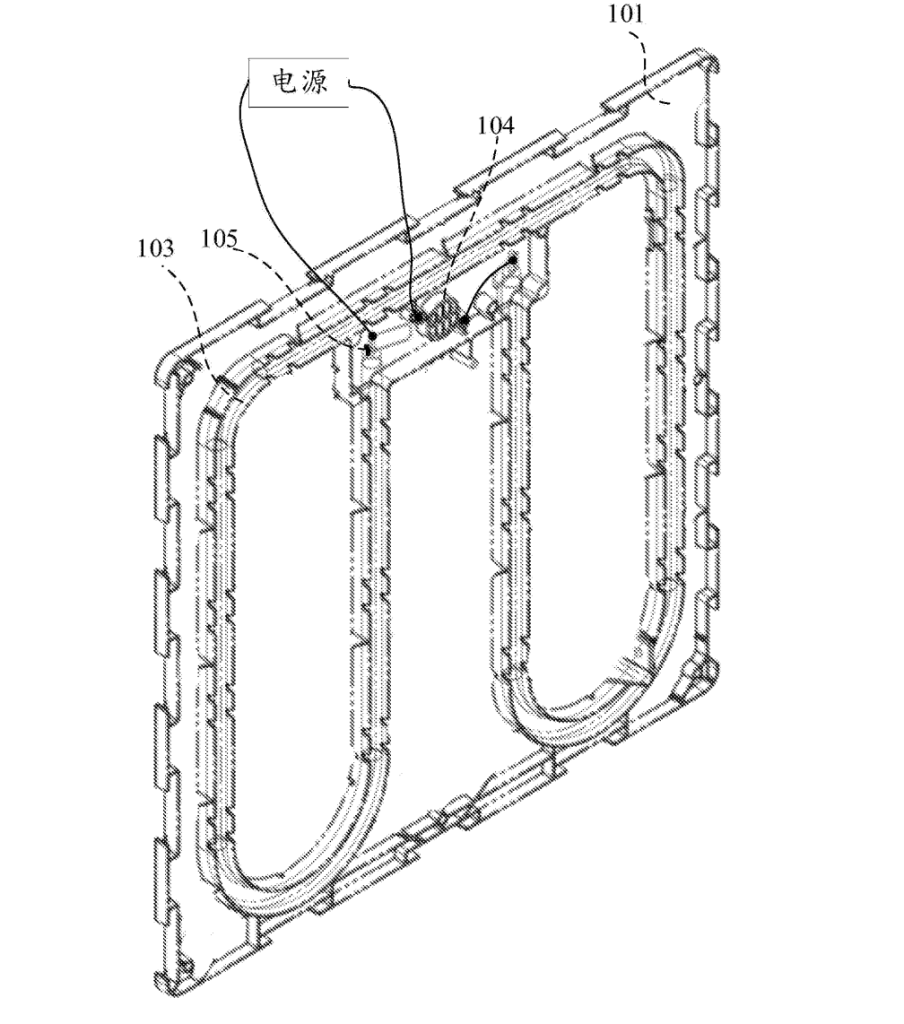

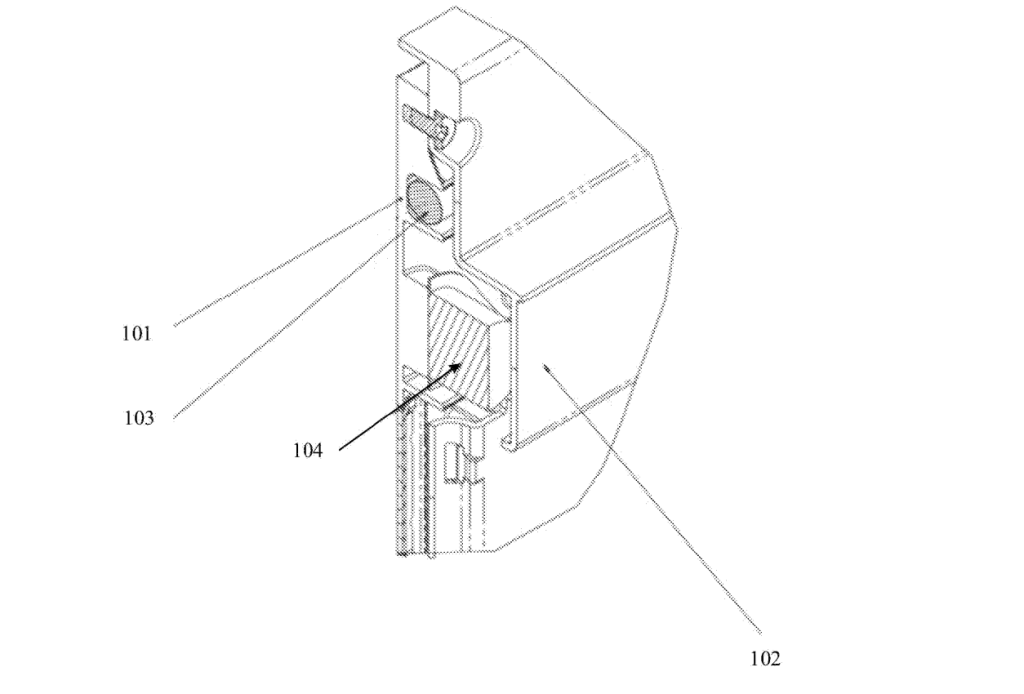

Shenzhen Tuozhu Know-how Co.’s patent describes a layered heatbed construction comprising the primary physique, a heating unit, and a backside shell. An insulation layer beneath the meeting minimises warmth loss, enhancing vitality effectivity. The design additionally incorporates a levelling detection module, which actively adjusts the heatbed to keep up a stage floor all through the printing course of, essential for print high quality and consistency.

On the coronary heart of the heatbed design is a concave or S-shaped channel, often known as the “first receiving groove”, embedded on the underside of the heatbed. This groove homes the heating ingredient, which might be secured by way of press-fitting, screws, or in-mould die casting. The design is meant to boost thermal switch and guarantee extra constant warmth distribution throughout the print floor, thereby enhancing adhesion and minimizing frequent 3D printing defects, comparable to warping.

The heating unit depends on both a warmth pipe or a resistance wire, changing typical aluminum substrates that mix each aluminum and copper. The totally different thermal growth charges of those metals can lead to uneven warmth distribution. In contrast, the usage of warmth pipes or resistance wire, as outlined within the patent, affords extra constant thermal efficiency whereas decreasing materials prices.

Security measures have additionally been taken into consideration. The design incorporates a sensor that displays the temperature of the heatbed. A change is related in collection with the ability provide to chop off energy if the temperature exceeds a secure restrict. This prevents overheating harm to 3D prints or the 3D printer.

The patent additionally introduces a segmented magnet system to boost mattress adhesion whereas reducing manufacturing prices. As an alternative of utilizing a single sheet of sentimental magnetic materials, the design incorporates two concentric arrays of magnets embedded inside the heatbed. Stronger magnets are positioned across the perimeter to anchor the print panel’s edges, the place warping generally happens. A central ring of weaker magnets reduces mechanical stress within the core, selling 3D print stability.

In keeping with the patent, this focused strategy helps to keep up heatbed flatness, enhances 3D print high quality, and optimizes magnetic pressure distribution. By minimizing the usage of high-strength magnets, the strategy reportedly lowers manufacturing prices with out compromising efficiency.

New 3D printing patents hit the headlines

The fixed stream of recent 3D printing patents underscores continued innovation in additive manufacturing. Earlier this 12 months, U.S. sportswear big Nike filed a patent for 3D printing sneakers. On this new technique, digital designs are 3D printed onto cloth materials to create the shoe’s higher. The only is then 3D printed straight onto this part, consolidating typical two-part shoe building methods right into a single step.

In keeping with the patent, US-12226973-B2, this new strategy unlocks superior materials customization, permitting designers to enhance power, rigidity, assist, flexibility, and abrasion resistance. By eradicating the necessity for heavy adhesives, stitching, and materials layers, shoemakers may create lighter footwear designs. This patent adopted a number of years of 3D printing at Nike, which started in 2013 when the Oregon-based agency unveiled its first 3D printed soccer boot.

In different information, Molecular Rebar Design, a nanomaterials firm primarily based in Austin, Texas, not too long ago patented a brand new technique that makes use of oxidized discrete carbon nanotubes (CNTs) with bonded dispersing brokers.

The patent, US-20210237509-A1, goals to boost the efficiency of 3D printable resins utilized in vat photopolymerization, sintering, and thermoplastic fusion. It does so by chemically functionalizing CNTs, attaching dispersing brokers on to their sidewalls. This strategy reportedly produces greater facet ratios and extra uniform dispersions. These enhanced dispersions mix into UV-curable acrylates, thermoplastics, and elastomers, delivering stronger inexperienced elements, higher sinterability, and sooner curing occasions.

Who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the newest 3D printing information.

It’s also possible to observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals a Schematic diagram of the construction of the heatbed design. Picture by way of the World Mental Property Group (WIPO).