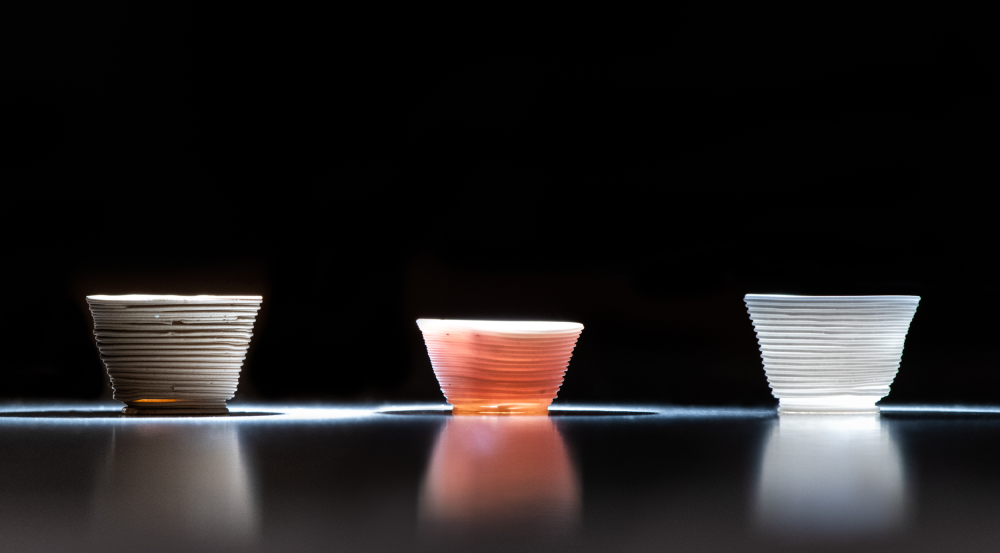

Researchers at MIT Lincoln Laboratory have developed a brand new low-temperature course of for 3D printing glass objects. This technique creates advanced glass buildings with out requiring the high-temperature processing usually related to glass manufacturing. The approach makes use of direct ink writing to construct objects layer by layer at room temperature, adopted by curing at simply 250°C—considerably decrease than the 1,000°C+ temperatures historically wanted for glass processing.

The method employs customized inks constructed from inorganic supplies mixed with a silicate answer. These parts enable engineers to tailor the optical, chemical, and electrical properties of the ensuing glass composite. After printing, the buildings are cured in a mineral oil bathtub after which rinsed with an natural solvent to take away residual materials.

Testing has demonstrated that the printed glass gadgets keep excessive decision, good thermal stability, and expertise minimal shrinkage throughout manufacturing. The tactic overcomes key limitations of standard 3D printing supplies like plastics and metals, which may undergo from mechanical, chemical, and thermal instabilities. Utilizing inorganic composite glasses addresses many of those points.

The approach may allow extra widespread adoption of glass in additive manufacturing functions. Potential makes use of embrace microfluidic methods, free-form optical lenses or fiber, and high-temperature digital parts. The strategy is especially precious for parts that might be tough or not possible to provide utilizing conventional glass manufacturing strategies.

Present analysis efforts are centered on enhancing the optical readability of the printed glass. Scientists are additionally growing new ink formulations to increase the vary of chemical and electrical properties accessible within the printed objects. The accessible nature of the ink components and the geometric freedom supplied by direct ink writing present vital versatility for creating specialised glass buildings.

Supply: ll.mit.edu