Researchers from Penn Engineering, Harvard College, Duke College, UC Berkeley, and Lawrence Livermore Nationwide Laboratory have developed a technique to 3D print cholesteric liquid crystal elastomers (CLCEs). The workforce’s work, revealed in Superior Supplies, permits the creation of color-changing supplies that reply to mechanical stress. CLCEs are tender, rubbery supplies that may manipulate gentle just like beetle shells, altering colour when subjected to bodily power.

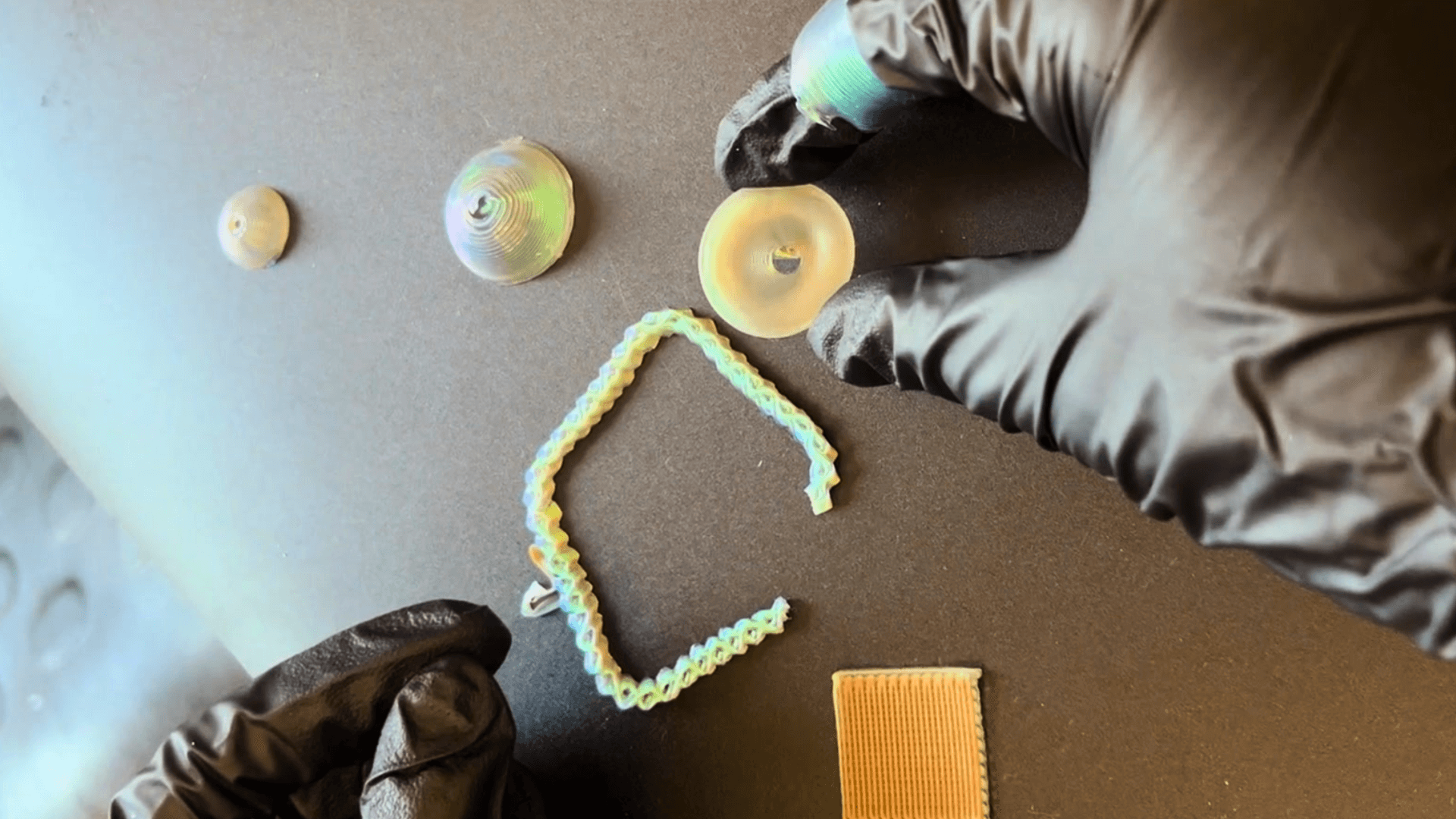

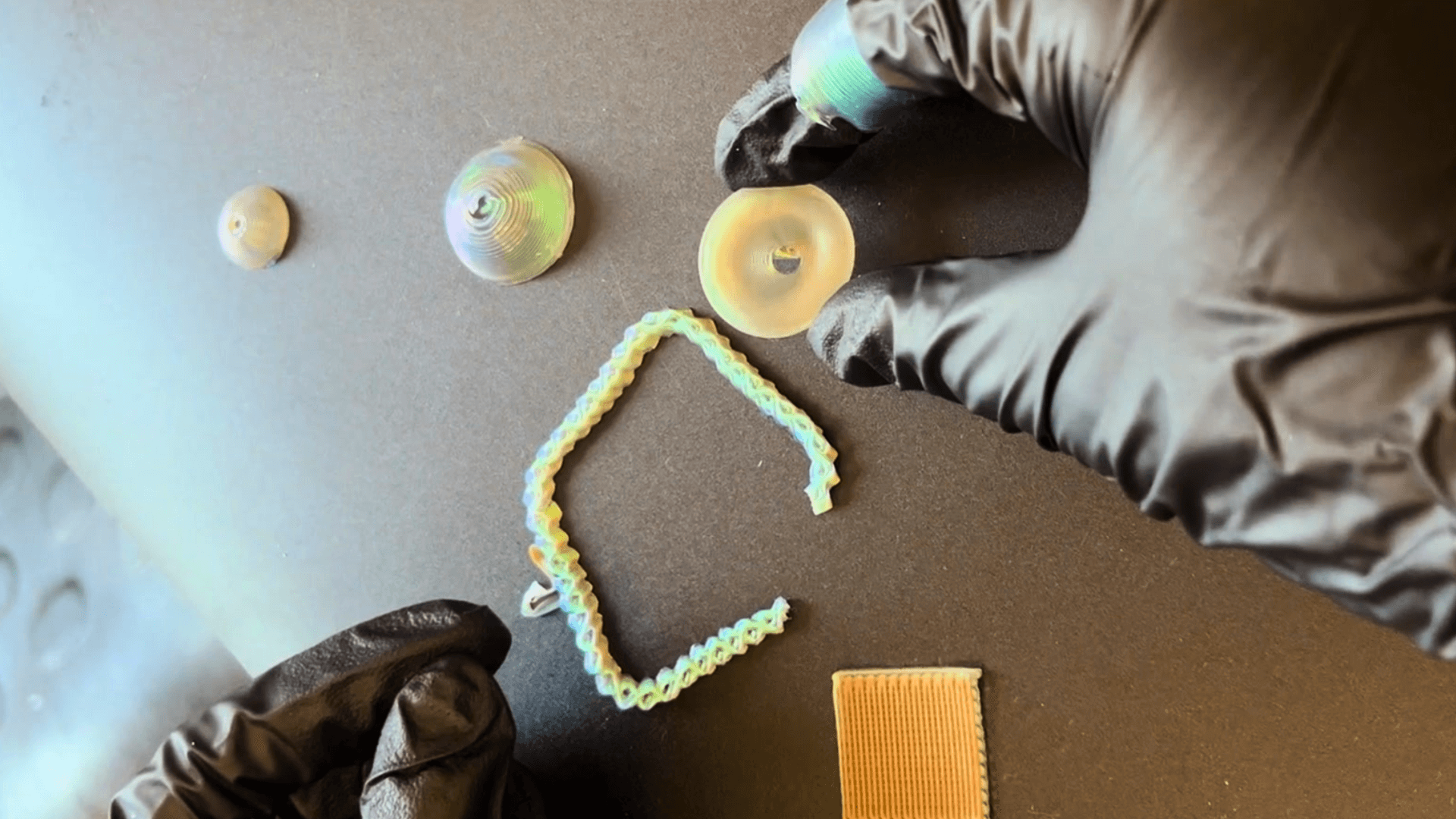

The brand new method makes use of Coaxial Direct Ink Writing (DIW), overcoming earlier limitations that confined CLCEs to 2D planar movies. Researchers solved a key problem by growing a clear silicone shell that serves as a scaffold for the CLCE core. “This distinctive mixture of supplies allowed us to protect the color-changing properties of the CLCEs whereas offering the mandatory structural power to help intricate 3D designs,” stated Alicia Ng, lead writer of the research.

Functions for this expertise span a number of industries together with healthcare, robotics, and environmental monitoring. The supplies could possibly be utilized in wearable gadgets that present visible suggestions about mechanical stress or swelling. Katherine Riley, mechanical engineer at LLNL, famous potential makes use of in “robotic grippers that may snap open and closed, metamaterial sheets that may passively sense and file mechanical hundreds, and mechanical logic techniques.”

The analysis workforce is exploring combos of CLCEs with temperature or light-responsive supplies to create multi-stimulus responsive supplies. They’ve already printed varied constructions together with lattices, wraps, and filaments, with plans to develop extra advanced designs. The workforce can also be contemplating extra environmentally pleasant approaches, probably incorporating parts from biofilms.

This collaborative venture benefited from the mixed experience in polymers, liquid crystal elastomers, and 3D printing throughout a number of establishments. Funding got here from the Nationwide Science Basis, Harvard MRSEC, the Military Analysis Workplace MURI program, and Lawrence Livermore Nationwide Laboratory. The analysis continues via an LLNL Laboratory Directed Analysis and Improvement Strategic Initiative geared toward growing “sentient” supplies.

Supply: weblog.seas.upenn.edu