Researchers on the College of Texas at Austin have developed a novel resin system for multicolor digital gentle processing (DLP) 3D printing that allows speedy fabrication of freestanding and non-assembly buildings utilizing dissolvable helps. The work, led by Zachariah A. Web page and revealed in ACS Central Science, combines UV- and visible-light-responsive chemistries to supply supplies with distinct solubility profiles, considerably streamlining post-processing.

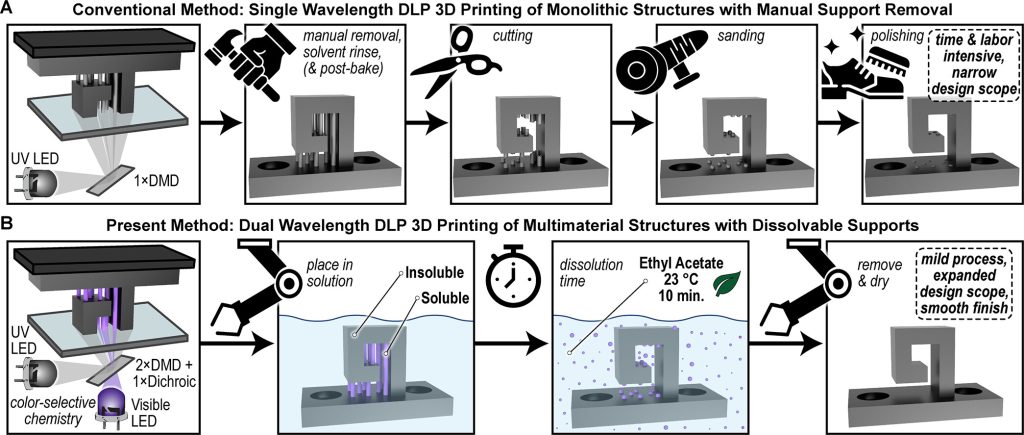

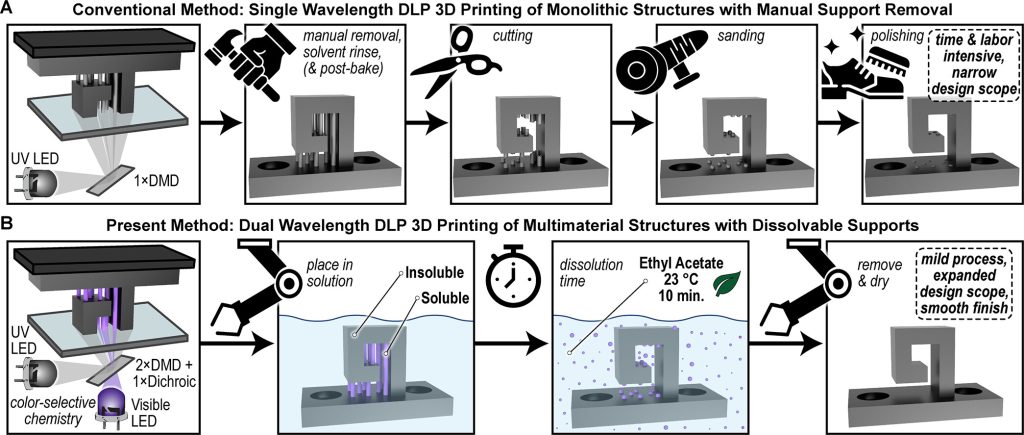

Present DLP workflows are sometimes restricted by the necessity for manually eliminated assist buildings, particularly when fabricating parts with overhangs or inner joints. These limitations constrain automation and improve manufacturing time and price. To beat this, the workforce designed wavelength-selective photopolymer resins that kind both an insoluble thermoset or a readily dissolvable thermoplastic, relying on the sunshine shade used throughout printing.

In sensible phrases, this enables helps to be printed in a single materials and quickly dissolved utilizing ethyl acetate, an environmentally pleasant solvent, with out affecting the first construction. The helps dissolve in below 10 minutes at room temperature, eliminating the necessity for time-consuming sanding or reducing.

The analysis was supported by the U.S. Military Analysis Workplace, the Nationwide Science Basis, and the Robert A. Welch Basis. The authors additionally acknowledge collaboration with MonoPrinter and Lawrence Livermore Nationwide Laboratory.

Excessive-resolution multimaterial printing

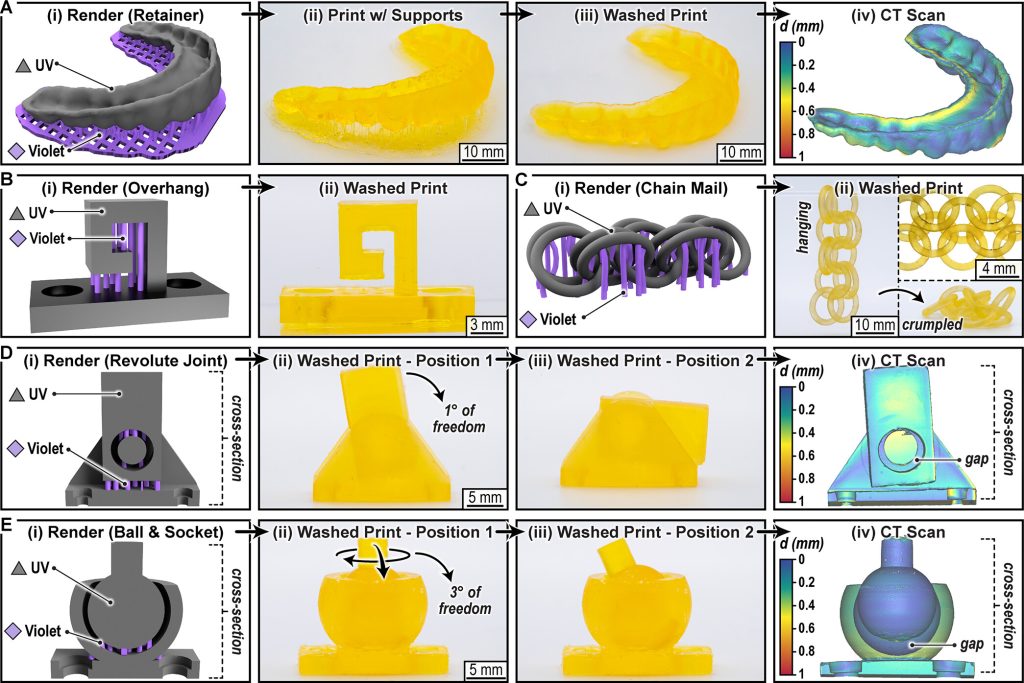

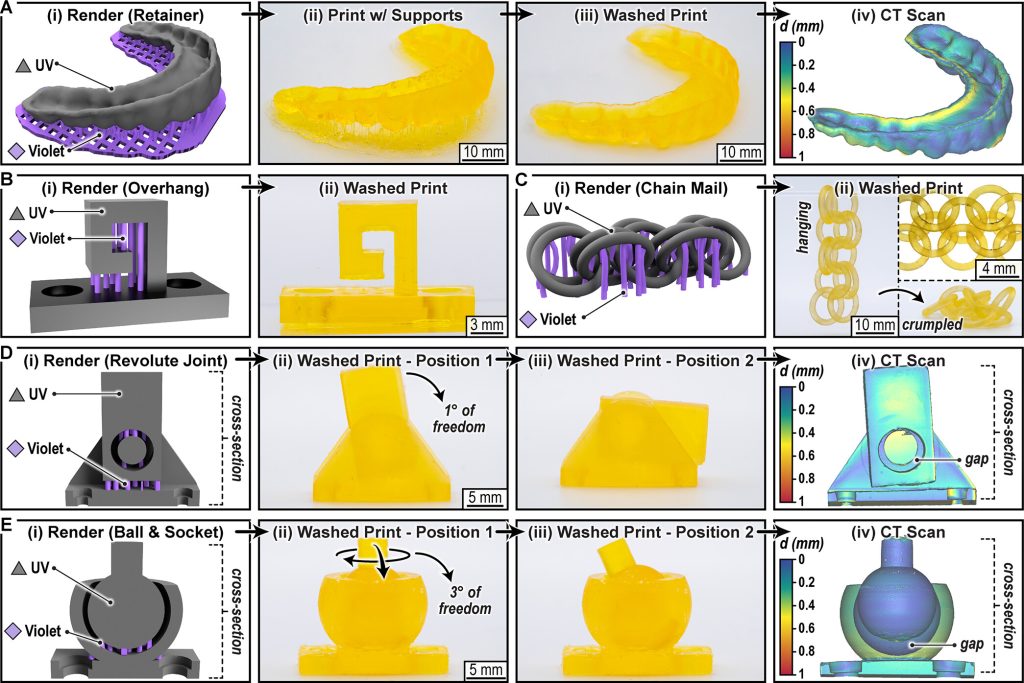

The analysis showcases how multicolor DLP can function a exact multimaterial platform, reaching sub-100 μm characteristic decision with layer heights as little as 50 μm. By tuning the photoinitiator and photoacid programs to reply selectively to ultraviolet (365 nm), violet (405 nm), or blue (460 nm) gentle, the workforce spatially managed polymer community formation in a single vat. This enabled the manufacturing of complicated, freestanding buildings resembling chainmail, hooks with unsupported overhangs, and absolutely enclosed joints, which historically require intensive post-processing or multi-step meeting.

The helps, printed in a visible-light-cured thermoplastic, demonstrated enough mechanical integrity through the construct, with tensile moduli round 160–200 MPa. But, upon immersion in ethyl acetate, they dissolved inside 10 minutes, leaving the UV-cured thermoset construction intact. Floor profilometry confirmed that together with a single interface layer of the dissolvable materials between the assist and the ultimate object considerably improved floor end, reducing roughness to below 5 μm with out sprucing. Computed tomography scans validated geometric constancy, with dimensional deviations from CAD information as little as 126 μm, reinforcing the tactic’s functionality for high-precision, solvent-cleared multimaterial printing.

In the direction of scalable automation

This work marks a big step towards automated vat photopolymerization workflows. By eradicating handbook assist removing and reaching clear floor finishes with minimal roughness, the tactic may benefit purposes in medical units, robotics, and client merchandise.

The authors recommend that future work might contain refining resin formulations to reinforce efficiency and print pace, probably incorporating new reactive diluents and opaquing brokers for improved decision.

Dissolvable supplies as post-processing options

Dissolvable helps have been a focus in additive manufacturing, notably for enhancing the effectivity of post-processing. In Fused Deposition Modeling (FDM), supplies like Stratasys’ SR-30 have been successfully eliminated utilizing specialised cleansing brokers resembling Oryx Additive‘s SRC1, which dissolves helps at twice the pace of conventional options. For resin-based printing, programs like Xioneer‘s Vortex EZ make use of warmth and fluid agitation to streamline the removing of soluble helps . In metallic additive manufacturing, improvements have led to the event of chemical processes that selectively dissolve assist buildings with out compromising the integrity of the primary half . These developments underscore the business’s dedication to lowering handbook intervention and enhancing the general effectivity of 3D printing workflows.

Learn the complete article in ACS Publications.

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

It’s also possible to observe us on LinkedIn and subscribe to the 3D Printing Business YouTube channel to entry extra unique content material.

At 3DPI, our mission is to ship high-quality journalism, technical perception, and business intelligence to professionals throughout the AM ecosystem.

Assist us form the way forward for 3D printing business information with our 2025 reader survey.

Featured picture reveals: Hook geometry printed utilizing multicolor DLP with dissolvable helps. Picture by way of College of Texas at Austin.