Tiny, adaptable robots now stroll, swim, and collaborate throughout assorted terrains due to a modular 3D-printed design, paving the way in which for versatile micro robotics in drugs, environmental monitoring, and past.

A brand new era of 3D-printed microrobots is breaking floor in adaptability and performance, promising to reshape how robotics can function throughout numerous real-world environments. Developed by researchers at Seoul Nationwide College, these modular microrobots—every smaller than a centimeter—can stroll on varied surfaces, swim, and even collaborate in teams, providing a serious leap towards general-purpose micro-scale robotics.

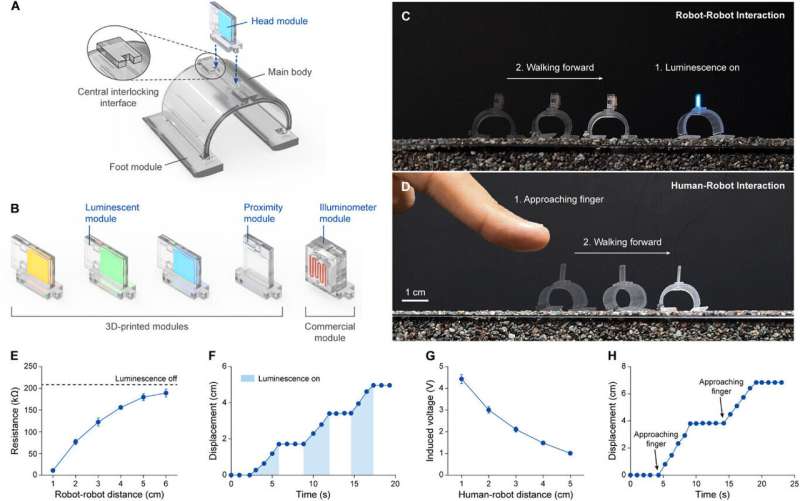

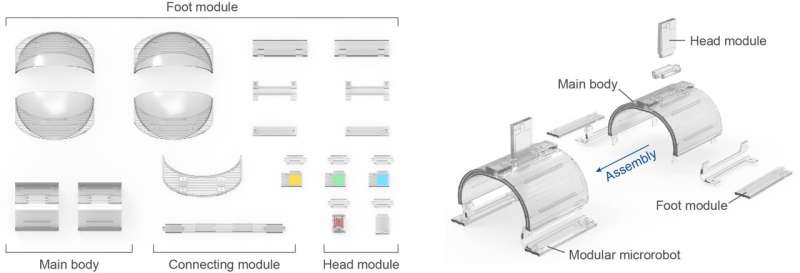

In contrast to conventional microrobots, which are sometimes purpose-built for slender functions similar to drug supply or illness diagnostics, these new techniques make use of a modular structure. This design permits researchers and engineers to swap parts for various duties, echoing the pliability seen in drone know-how. Every robotic consists of a central physique linked to interchangeable modules: legs for motion throughout flat, tough, or aquatic terrains; heads for real-time interplay; and connectors that enable a number of models to function as one coordinated swarm.

The important thing development lies in fabrication. The crew used a customized multi-material 3D printer able to producing as much as eight an identical microrobot models per run, dramatically bettering scalability and precision. This course of not solely hurries up manufacturing but in addition allows on-demand customization—modules may be printed or reconfigured for particular missions, from environmental monitoring to focused biomedical operations.

In testing, the microrobots demonstrated sturdy locomotion throughout sand, water, and strong floor, sustaining stability and coordination even in difficult situations. The researchers credit score their modular design for this versatility, permitting the robots to imitate pure adaptability seen in bugs whereas remaining extremely controllable.

The implications stretch far past the lab. Modular microrobotics might finally allow swarms of micro-machines to navigate confined or hazardous areas, help in minimally invasive surgical procedure, or carry out distributed sensing in environmental analysis. The 3D printing course of additionally paves the way in which for reasonably priced, large-scale manufacturing—a vital step towards commercialization.

By merging modular structure with superior 3D-printing supplies, Seoul Nationwide College’s analysis indicators a future the place microrobots are usually not simply tiny specialists however dynamic, general-purpose techniques able to function in nearly any atmosphere.