Researchers from the École Polytechnique Fédérale de Lausanne (EPFL) have launched a compact, high-efficiency holographic tomographic volumetric additive manufacturing (HT-VAM) system that leverages a MEMS-based phase-only mild modulator. This improvement marks a big development in addressing the sunshine supply limitations related to volumetric 3D printing.Their work, detailed in a preprint on arXiv (June 2025) demonstrates how part modulation can revolutionize light-based fabrication, enabling sooner, higher-resolution prints with unprecedented power effectivity.

Holography meets volumetric manufacturing

Volumetric Additive Manufacturing (VAM) is a layerless 3D printing approach that cures complete objects concurrently by projecting mild patterns right into a rotating vial of photoresin. In contrast to layer-by-layer strategies, VAM eliminates stair-stepping artifacts and permits support-free fabrication of advanced geometries. EPFL’s method, Tomographic VAM (TVAM), adapts computed tomography ideas to generate dynamic mild fields that polymerize resin volumetrically.

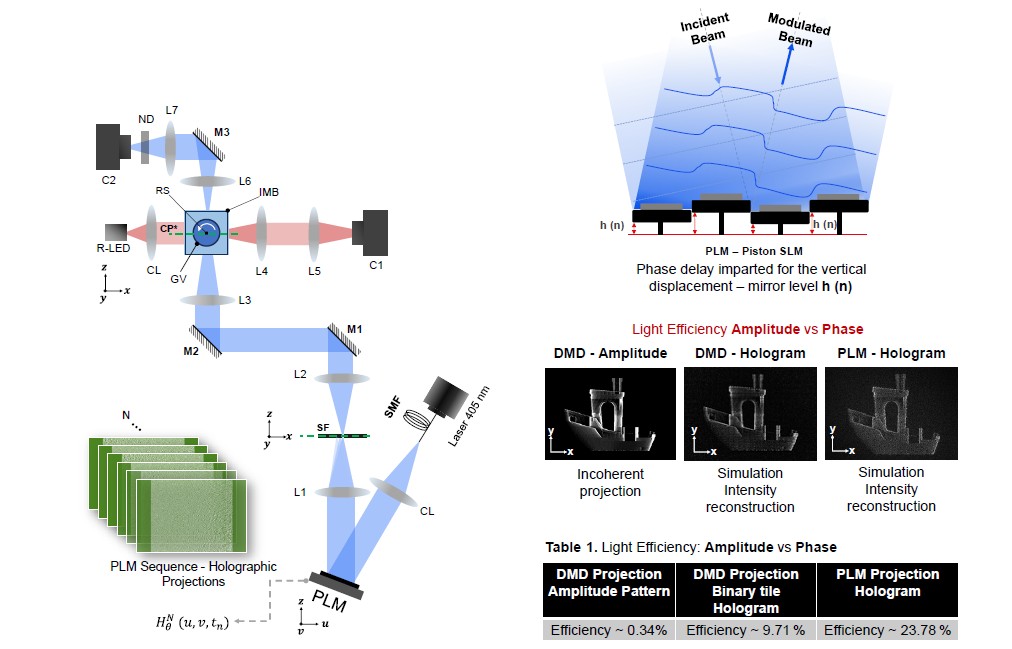

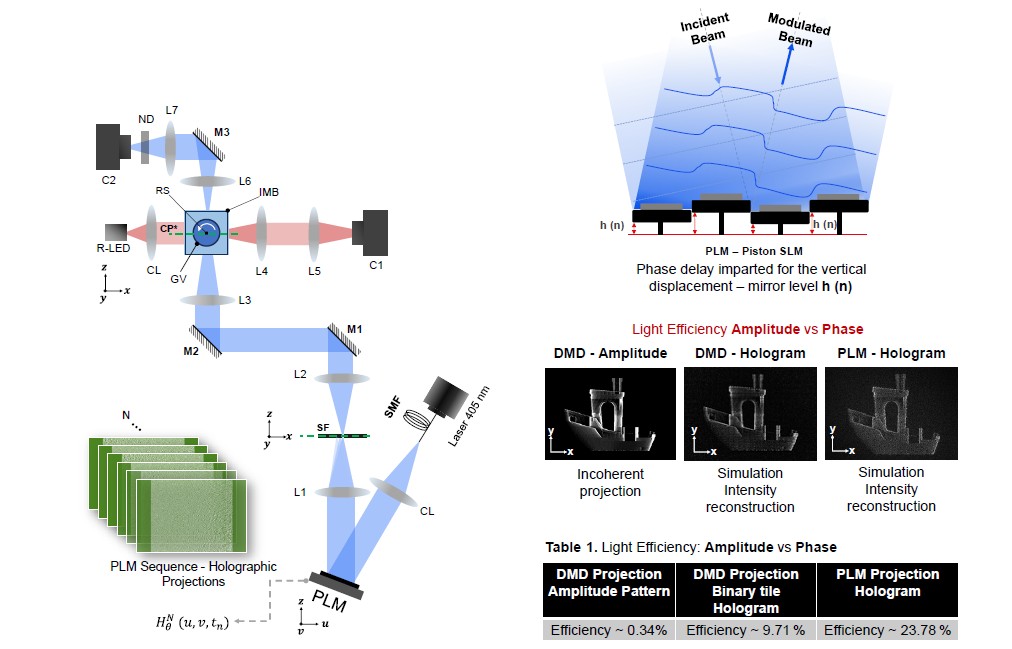

Conventional TVAM programs usually depend on Digital Micromirror Units (DMDs), binary amplitude modulators with restricted mild effectivity, sometimes under 10%. The EPFL staff replaces these with a phase-only Part Gentle Modulator (PLM), which permits exact wavefront management. This variation leads to a measured mild effectivity of 23.78%, representing a 70× enchancment over DMDs, whereas additionally lowering imaging artifacts like speckle noise.

Part Modulation: A Sport Changer

Till not too long ago, Liquid Crystal on Silicon (LCOS) Spatial Gentle Modulators (SLMs) have been the usual for part modulation. Nonetheless, LCOS suffers from limitations together with sluggish response instances (60–120 Hz), ultraviolet (UV) degradation, and polarization sensitivity.

In distinction, EPFL’s MEMS-based PLM, developed by Texas Devices, makes use of piston-motion micromirrors to encode part immediately. It incorporates a 4-bit decision (16 part ranges) for exact wavefront shaping, excessive pace (1,440 Hz body fee) for fast patterning and polarization insensitivity and UV stability, important for photopolymerization.

This structure permits the usage of low-power, single-mode 405 nm lasers, decreasing each price and system complexity whereas attaining near-theoretical diffraction effectivity.

Speckle Discount and Print High quality

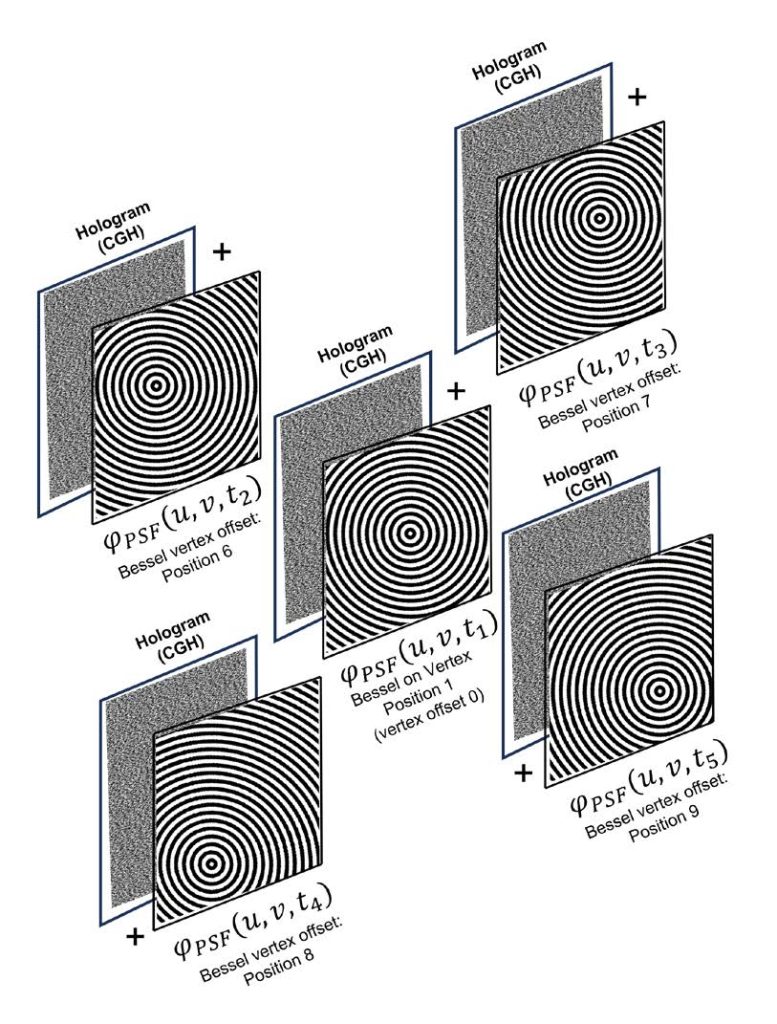

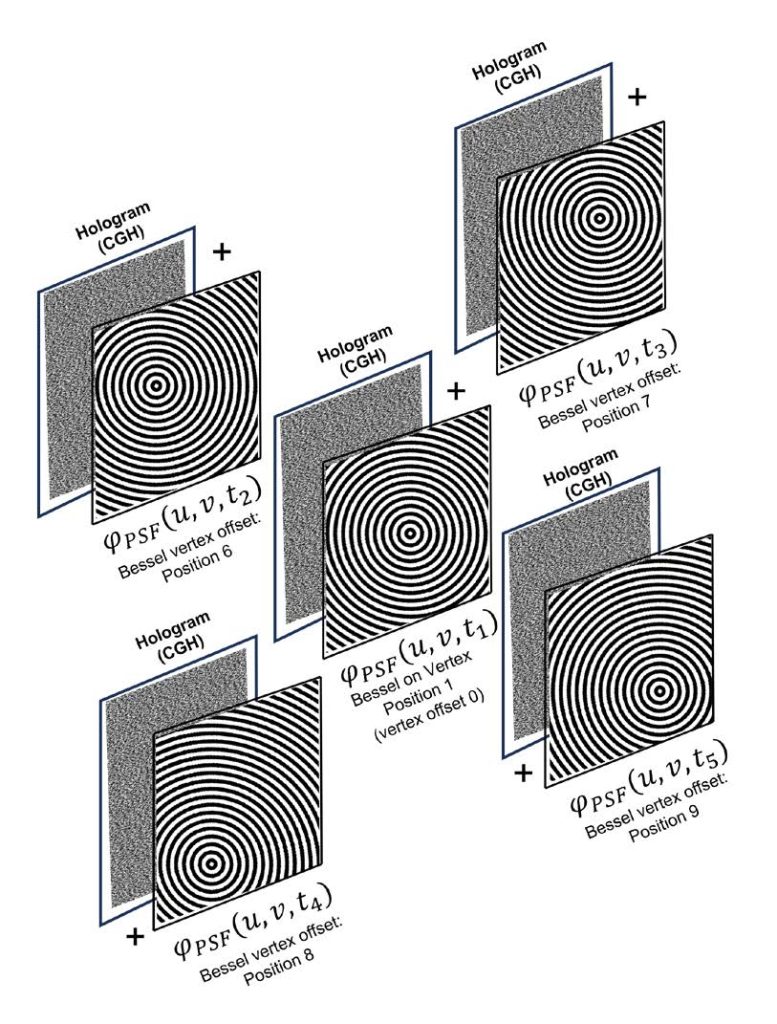

A key innovation lies within the system’s speckle-reduction pipeline. Speckle, attributable to interference in coherent mild, was mitigated by means of time-multiplexed projection of 9 laterally shifted holograms per angle. Mixed with Bessel beam axicon phases, this lowered speckle distinction by 50% (from 0.45 to 0.33) and prolonged the system’s depth of focus, making certain uniform decision all through the print quantity.

Speedy, high-fidelity printing

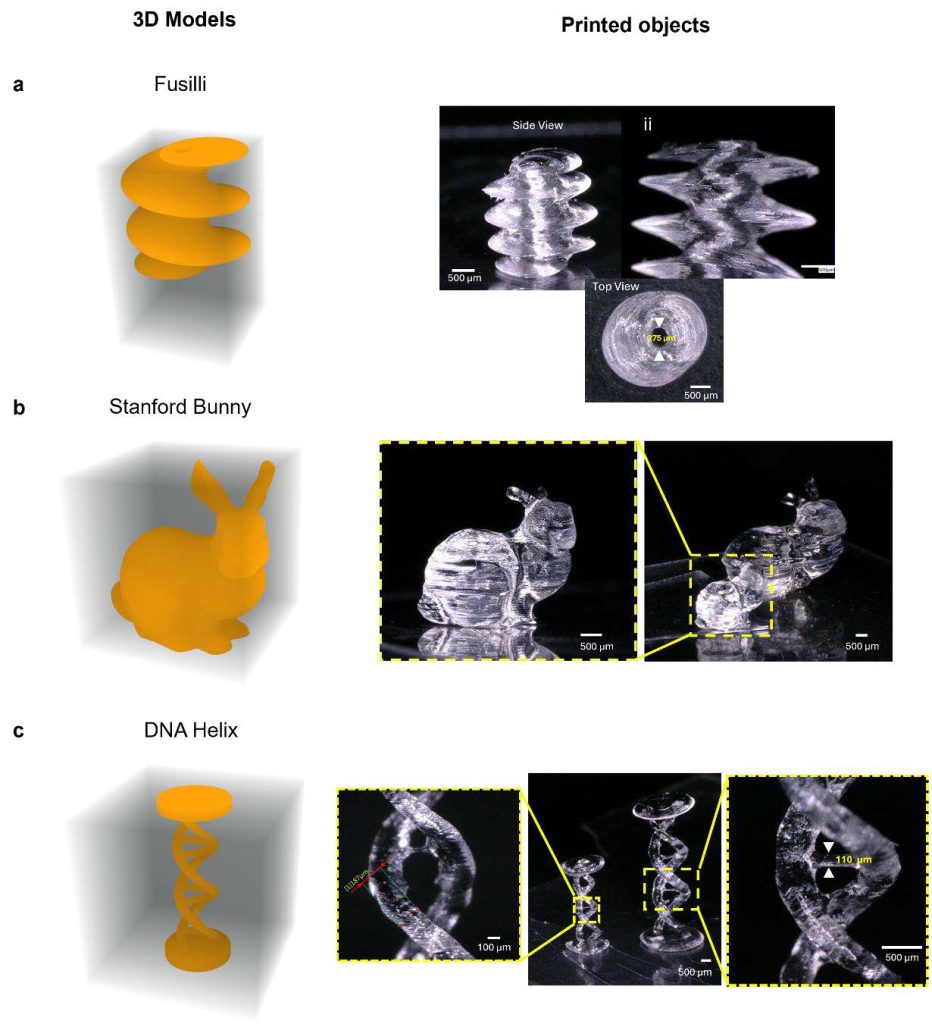

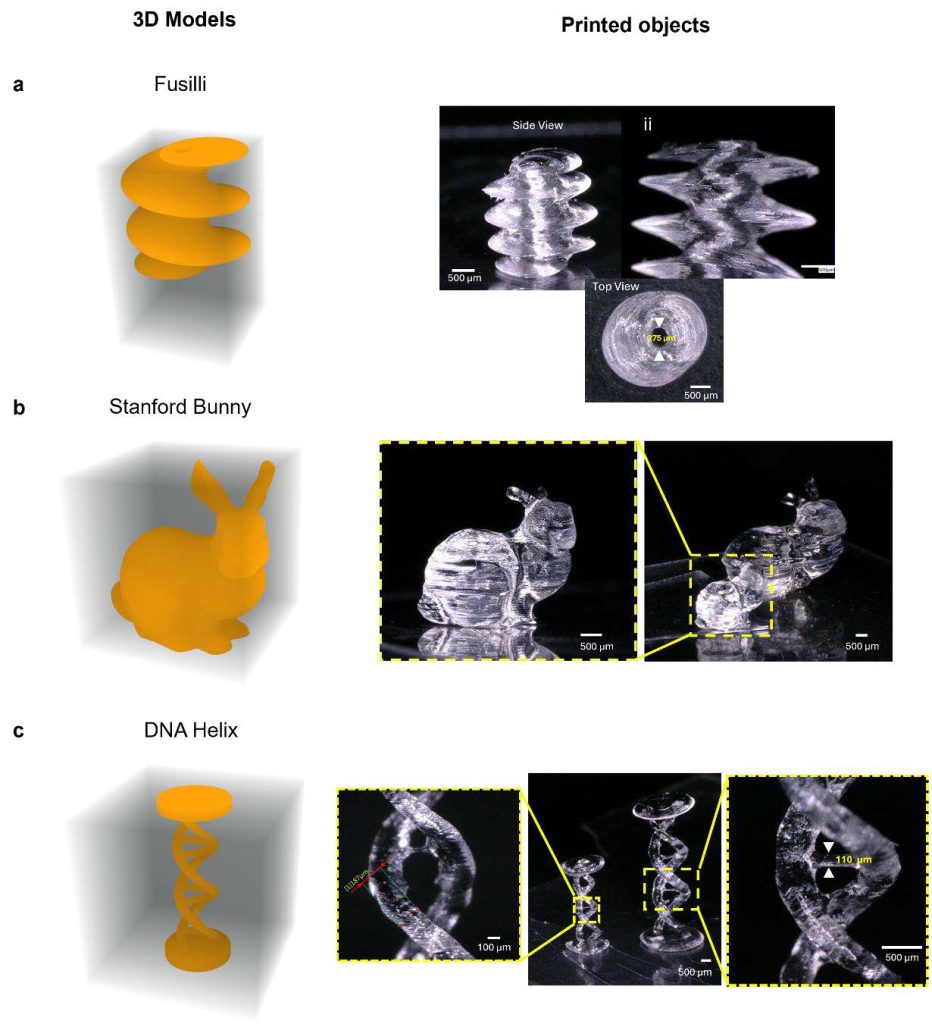

The system demonstrated fast printing of advanced fashions, corresponding to a 4 mm fusilli pasta construction in 32 seconds (18 mW laser energy), a Stanford Bunny (8 mm tall) in 61 seconds (50 mW) and DNA helices with clean surfaces at micrometer scales. Potential functions span bioprinting, micro-optics, and aerospace, the place pace, decision, and materials effectivity are important.

Volumetric printing matures with improvements in mild management and biomedical functions

Volumetric additive manufacturing has gained momentum as a promising various to conventional layer-by-layer 3D printing, providing the power to manufacture complete objects concurrently with fewer constraints on geometry and pace. Latest advances embrace automated publicity management programs for extra exact mild dosing throughout tomographic projection, and the usage of light-converting nanoparticles to allow deeper and extra managed polymerization. Swiss agency Readily3D, a spin-off from EPFL, has additionally superior volumetric bioprinting by means of its collaborations with BIO INX, aiming to simplify the fabrication of advanced organic fashions.

Register for our upcoming occasion Additive Manufacturing Benefit: Aerospace, Area and Protection.

What 3D printing tendencies do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals floor high quality enchancment comparability. Picture by way of Laboratory of Utilized Photonics Units (LAPD), EPFL.