LaserTool, a Scandinavian firm specializing in laser hardening, is coming into the additive manufacturing (AM) sector with the acquisition of an SLM 500 steel 3D printer from steel 3D printer producer Nikon SLM Options. The funding is meant to satisfy rising regional demand for high-strength metal parts whereas additionally supporting the development of additive manufacturing capabilities in Northern Europe, notably in functions requiring strong materials efficiency.

Constructing on greater than twenty years of expertise in laser hardening, LaserTool goals to leverage its experience to fabricate giant structural parts, spare elements, tooling, and prototypes utilizing high-strength metal powders supplied by SSAB. To help this growth, the corporate is growing its manufacturing area by 400 sq. meters to accommodate the brand new gear and ramp up operations.

“We’re proud to help LaserTool’s bold growth into additive manufacturing,” mentioned Sam O’Leary, CEO of Nikon SLM Options. “Our collaboration marks a major milestone in accelerating AM adoption throughout the Nordic area.”

Sustainability and AM Integration with the SLM 500 System

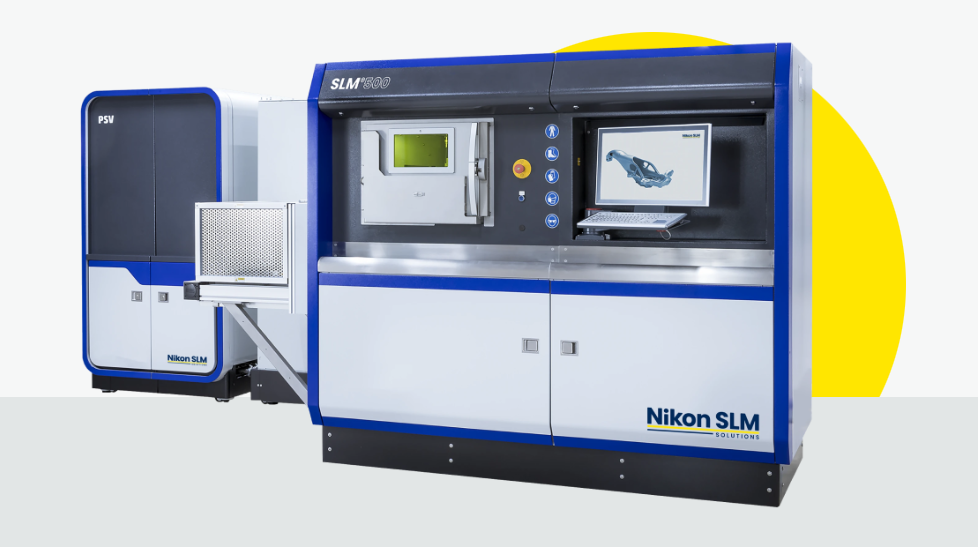

The SLM 500 system is designed for high-throughput manufacturing of advanced steel elements and is suited to each prototyping and collection manufacturing. LaserTool defined that its AM operations shall be powered by renewable power sources, in step with the corporate’s said sustainability aims. Set up and commissioning of the system are anticipated within the second quarter of 2025.

“With this funding, LaserTool will meet rising market demand and strengthen our aggressive edge as a complete manufacturing accomplice,” mentioned Martin Nilsson, CEO of LaserTool. “Additive manufacturing opens new alternatives, enabling us to create parts that have been beforehand inconceivable with standard strategies, considerably lowering materials waste, and enhancing our environmental footprint.”

Nikon’s Partnerships in Additive Manufacturing

LaserTool’s funding displays a wider development amongst corporations aiming to broaden their capabilities in superior manufacturing applied sciences. In March, Nikon Company was chosen by the Japan Aerospace Exploration Company (JAXA) as a expertise growth accomplice underneath the FY2024 Area Technique Fund (SSF). The collaboration focuses on additive manufacturing for light-weight, high-performance, and cost-efficient area transportation techniques. Nikon will contribute by way of using its NXG XII 600 platform and home manufacturing infrastructure, with the objective of lowering manufacturing prices and lead instances for giant precision area parts.

Individually, Veeco, a producer within the semiconductor and compound semiconductor industries, has acquired the NXG XII 600 system as a part of its technique to combine AM into its manufacturing processes. The system shall be used to fabricate advanced parts resembling fuel supply techniques, manifolds, and warmth exchangers. Veeco goals to enhance precision and effectivity through the use of AM to provide designs which might be tough to attain by way of standard manufacturing.

In 2024, Nikon SLM Options prolonged its partnership with steel alloys specialist Howco Metals Administration LLC to boost 3D printing for aerospace. This renewed collaboration has seen Howco purchase two new SLM 280 PS 3D printers, bringing its whole variety of SLM techniques to 4. These newly adopted 3D printers kind a part of an unique initiative to develop and deploy course of parameters for C-103 alloy, tailor-made to aerospace functions.

What 3D printing developments do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or observe us on LinkedIn.

Whilst you’re right here, why not subscribe to our YouTube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Function picture exhibits the SLM 500 3D printing system. Picture by way of Nikon SLM Options.