Inside Boston Youngsters’s Hospital, 3D printing and digital planning are “reworking” pediatric care. The 156-year-old establishment makes use of Materialise’s Mimics software program to show two-dimensional affected person scans into detailed 3D fashions, streamlining preoperative planning and enhancing surgical outcomes.

Dr. David Hoganson, a pediatric cardiac surgeon on the Massachusetts-based well being middle, known as 3D expertise a “complete game-changer” for clinicians. Talking on the Materialise 3D Printing in Hospitals Discussion board 2025, he outlined his position in main the hospital’s Cardiovascular 3D Modelling and Simulation Program.

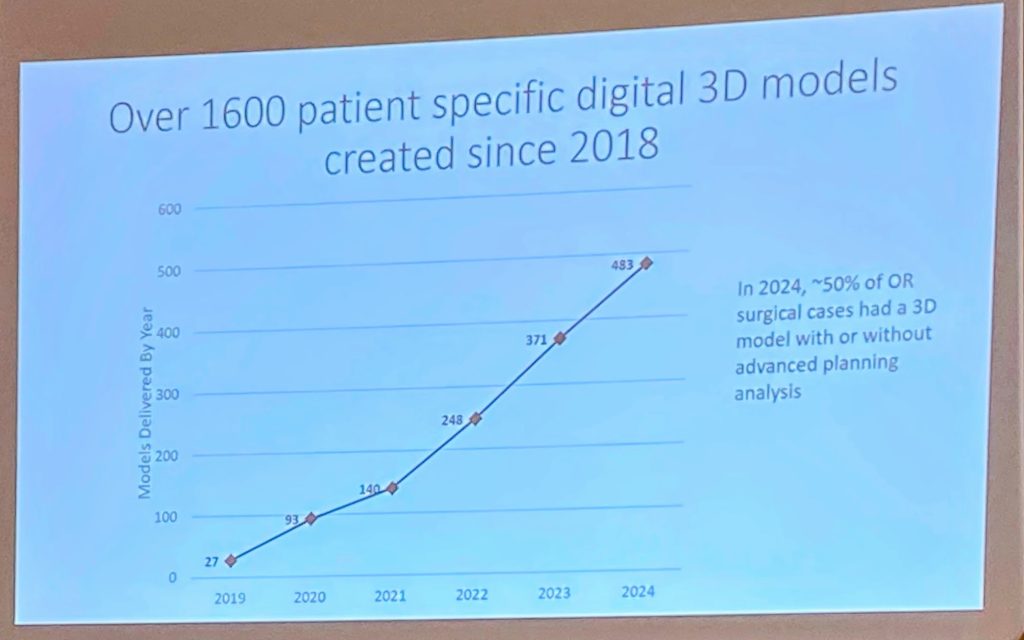

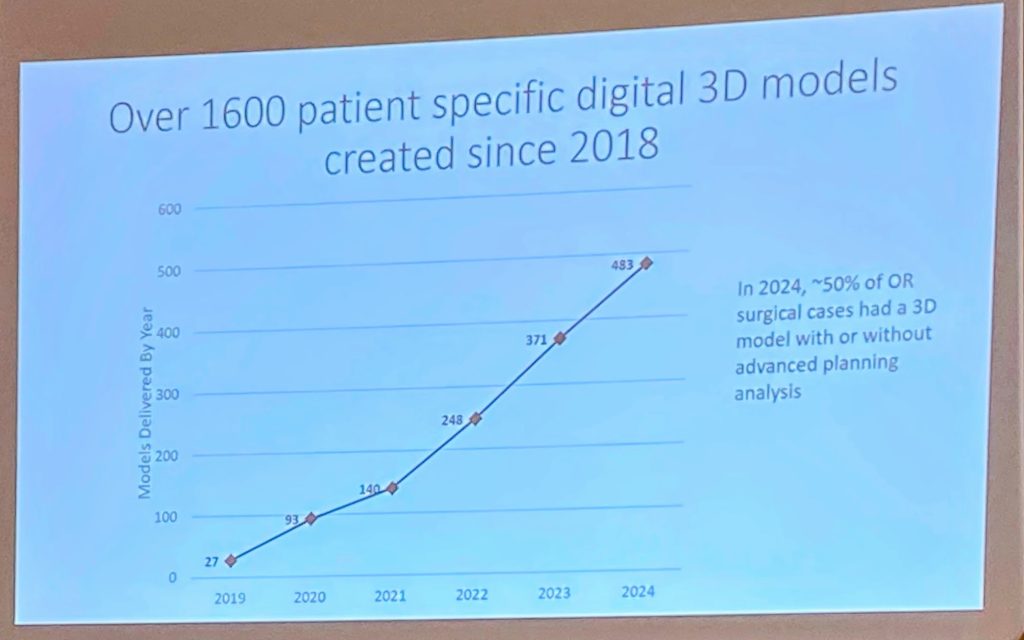

Mimics has change into a part of routine care at Boston Youngsters’s Benderson Household Coronary heart Middle. Since 2018, the Program’s engineers and clinicians have created over 1,600 patient-specific 3D fashions. Final yr alone, the group made 483 fashions, which accounted for about 50% of its Working Room surgical circumstances.

Throughout Materialise’s healthcare discussion board, I spoke with Dr. Hoganson about his distinctive path from biomedical engineering to scientific observe. The Temple College graduate outlined how 3D modeling is now not a futuristic add-on however a vital device reworking the precision and planning of recent surgical procedure.

He revealed the tangible advantages of Mimics modelling versus conventional medical imaging, emphasizing how intraoperative 3D planning can scale back coronary heart surgical procedure problems by as much as 87%. Seeking to the way forward for healthcare, Dr. Hoganson mentioned the necessity for extra seamless scientific integration, validation, and monetary reimbursement to extend adoption.

From the manufacturing unit ground to the working theater

When Dr. Hoganson started his profession, it wasn’t in an working room however on the manufacturing unit ground. He began as a biomedical engineer, creating cardiovascular medical gadgets for 2 years, earlier than transitioning to medication.

This pedigree has been instrumental in shaping Boston Youngsters’s 3D Modeling and Simulation Program, which was co-founded by College of New Hampshire Mechanical Engineering graduate Dr. Peter Hammer. The group has grown to incorporate 17 engineers and one scientific nurse. “It has been an engineering-focused effort from the start,” defined Dr. Hoganson. He emphasised that the group prioritizes utilizing “superior engineering evaluation” to plan and conduct ultra-precise operations.

Dr. Hoganson believes this engineering focus challenges the structured nature of scientific medication. “The mindset of drugs is way more targeted on doing issues the way in which we have been taught,” he explains. In distinction, engineering embraces fixed iteration, creating area for innovation and rethinking established practices.

He argued that engineers aren’t “held again by the way in which medication has at all times been achieved,” which makes them a useful asset in scientific settings. When engineers deeply perceive scientific challenges and apply their analytical expertise, they typically uncover options that physicians could not have thought-about, he added. These vary from optimized surgical workflows to thoroughly new approaches to preoperative planning. For Dr. Hoganson, the “secret sauce” lies in collaboration and making certain “zero distance between the engineers and the issue.”

3D printing and digital planning improve surgical outcomes

In pediatric cardiac surgical procedure, velocity issues. In keeping with Dr. Hoganson, that is why digital 3D modeling takes precedence in pre-operative planning and intraoperative steering. Materialise’s Mimics software program streamlines this course of. Customers can import CT and MRI knowledge, which is robotically remodeled into detailed, interactive 3D fashions. Surgeons can then run simulations and apply computational fluid dynamics to forecast the best therapy methods.

Boston Youngsters’s 3D simulation lead described these capabilities as providing “large advantages” past what conventional imaging alone can present. Conventional scans are considered in stacks of two-dimensional slices. Whereas, Mimics 3D fashions provide digital segmentation, inside views, and exact spatial mapping. Dr. Hoganson known as this a “distinction maker” and “completely transformational” for surgeons.

Dr. Hoganson’s group makes use of this expertise to carry out a spread of advanced cardiovascular repairs, equivalent to reconstructing aortic and mitral valves, closing ventricular septal defects (VSDs), and augmenting blood vessels, together with pulmonary arteries and aortas. Materialise Mimics’ worth isn’t restricted to preoperative preparation. It additionally guides surgical procedures. Throughout operations, clinicians can work together with the fashions utilizing repurposed gaming controllers, permitting them to discover and isolate anatomical options within the working theater.

One key breakthrough has been figuring out and mapping the center’s electrical system, which governs its rhythm. By integrating 3D modelling into intraoperative planning, surgeons have considerably lowered the chance of coronary heart block, the place electrical alerts are delayed as they cross via the organ. With the assistance of Mimics software program, incidence charges have fallen from 40% to as little as 5% in some circumstances.

Given some great benefits of digital modelling, surgeons is likely to be tempted to sideline bodily 3D printing altogether. Nonetheless, Dr. Hoganson insists additive manufacturing stays important to refining surgical workflows. His group conducts a “large quantity of 3D printing,” creating patient-specific anatomical fashions, principally with a resin-based Formlabs system. These fashions enable clinicians to check and validate plans within the lab earlier than donning their scrubs.

Boston Youngsters’s has sharpened its surgical edge through the use of supplies that intently replicate the mechanical properties of goal tissues. This enables the group to 3D print anatomical fashions tailor-made to every little one’s measurement, age, and bodily make-up.

As an illustration, Dr. Hoganson’s group can fabricate neonatal-sized aortas and pulmonary arteries that replicate the feel and elasticity of an toddler’s vessels. Developed over a number of years, this method allows correct simulation of advanced procedures, equivalent to patch enlargement of pulmonary arteries. The group conducts rigorous preclinical testing by combining anatomical precision with lifelike tissue mechanics.

Dr. Hoganson defined that in-depth testing is essential for refining strategies, lowering surgical danger, and minimizing problems in pediatric sufferers. This, in flip, slashes healthcare prices as fewer youngsters spend prolonged time within the ICU following procedures. 3D planning and simulation empower surgeons to “do issues proper the primary time, so we are able to scale back these reinterventions and problems,” Dr. Hoganson added.

Overcoming challenges to adoption in hospitals

What key challenges are limiting scientific adoption of 3D expertise? For Dr. Hoganson, value stays a important barrier. “Having the efforts reimbursed might be an important piece of this,” he defined. “That allows groups to develop and have the manpower to do it,” when 3D planning is clinically needed. Within the US, medical reimbursement includes an extended path to approval. However progress is being made. His group has began billing efficiently for some features of the work, marking an “encouraging begin” towards broader systemic change.

Adoption additionally hinges on simpler integration into present workflows. Dr. Hoganson famous that if 3D expertise provides efforts and time to procedures, it received’t be chosen over present strategies. Subsequently, “the extra streamlined you can also make the entire course of for the doctor, the extra probably they’re to undertake it.”

In response to those calls for, Boston Youngsters’s 3D Modelling and Simulation Program has designed a system that feels acquainted to surgeons. “It’s not nearly offering the technical features of the 3D mannequin,” added Dr. Hoganson. “It’s about integrating the entire course of into the scientific workflow in a means that works for the clinician.”

His group works on the middle of those efforts, making certain “there’s virtually no barrier of entry to search out and use the mannequin they want.” Dr. Hoganson claims to have simplified the method to the stage the place it seems and looks like common medical care, eradicating the mystique and misconceptions round 3D expertise. “There’s nothing particular about it anymore,” he added. “That’s been an enormous step in the direction of this expertise being part of routine medical care.”

Boston Youngsters’s integration technique is working. The group expects to make use of 3D fashions in round 60% of coronary heart surgical procedures this yr. Nonetheless, making 3D expertise a regular of care has not been straightforward. Dr. Horganson stated, “It has taken a really diligent effort to take away these boundaries.”

Within the broader tech area, 3D printing has typically suffered from overpromising and underdelivering, a sample Dr. David Hoganson is eager to keep away from. “We’ve tried to be extraordinarily clear with what’s and isn’t being delivered,” he added. That readability is essential for constructing belief. A 3D mannequin alone, as an illustration, serves a significant however outlined position: enhanced visualization and preoperative measurements. Hoganson emphasised that 3D printing isn’t a miracle remedy, however one other device in a surgeon’s toolbox.

For Boston Youngsters’s, the way forward for 3D printing in healthcare lies past static fashions. Dr. Horganson believes additive manufacturing might be a foundation for “taking the subsequent step and impacting how surgical procedure is carried out, and the way exactly and completely it’s achieved the primary time.”

Over the subsequent eighteen months, Dr. Hoganson’s group will double down on demonstrating how preoperative 3D modeling interprets into higher surgical procedures. This may embody measuring outcomes from surgical procedures utilizing 3D expertise and assessing whether or not predictions have matched surgical outcomes. He believes validating outcomes might be an “vital step ahead” in shifting 3D modeling from supportive expertise to an indispensable scientific customary.

Take the 3DPI Reader Survey – form the way forward for AM reporting in underneath 5 minutes.

Learn all of the 3D printing information from RAPID + TCT 2025

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the most recent 3D printing information.

You can too observe us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits Dr. David Hoganson talking on the Materialise 3D Printing in Hospitals Discussion board 2025. Picture through Materialise.

![[INTERVIEW] 3D Printing at Boston Youngsters’s Hospital: Engineering the Way forward for Pediatric Surgical procedure [INTERVIEW] 3D Printing at Boston Youngsters’s Hospital: Engineering the Way forward for Pediatric Surgical procedure](https://i2.wp.com/3dprintingindustry.com/wp-content/uploads/2025/05/Dr.-David-Hoganson-speaking-at-the-Materialise-3D-Printing-in-Hospitals-Forum-2025.-Photo-via-Materialise3.jpg?w=696&resize=696,0&ssl=1)