South Korean area firm INNOSPACE has launched an Superior Manufacturing Division specializing within the manufacturing of rocket engines and demanding elements for area launch automobiles by means of proprietary metallic additive manufacturing (AM) know-how.

This transfer enhances the corporate’s manufacturing autonomy and scalability, enabling value reductions, quicker improvement cycles, and stronger competitiveness within the industrial launch sector. It additionally positions INNOSPACE for future development in industries like automotive and semiconductors.

Value Effectivity and Operational Advantages of Additive Manufacturing

In launch car improvement, the place frequent design modifications and rigorous testing are important, 3D printing supplies an environment friendly method to shorten manufacturing timelines and guarantee constant high quality, whereas sustaining excessive reliability. Constructing on this functionality, INNOSPACE estimates that integrating AM into its processes may reduce prices by as much as 50% in comparison with conventional strategies, because of decreased materials waste, simplified manufacturing steps, and extra streamlined workflows.

“The brand new division marks a pivotal milestone to internalize manufacturing of core elements together with launch car engines, securing our distinctive competitiveness in launch service,” stated founder and CEO Soojong Kim. “By making use of 3D printing know-how, we anticipate to attain half lightweighting that reduces rocket mass and will increase payload capability, permitting clients to move extra satellites at a decrease value.”

Certification Milestone and Manufacturing Progress

The Superior Manufacturing Division started full-scale operations after efficiently passing a cargo inspection beneath ISO/ASTM 52941-20, the worldwide customary for aerospace-grade metallic AM methods. INNOSPACE is the primary firm in South Korea to earn this certification. The division operates by means of a totally built-in, end-to-end manufacturing system that consolidates all phases of manufacturing—from design and improvement to 3D printing, simulation, floor therapy, machining, and high quality management—inside a single, streamlined workflow.

So far, the division has accomplished course of improvement and preliminary manufacturing of 13 key elements for the HANBIT launch car, together with oxidizer pumps for each phases and high-precision rotating elements, enhancing course of reliability and manufacturing readiness.

By the top of the 12 months, INNOSPACE plans to stabilize the 3D printed manufacturing of launch car engines and demanding elements, set up a data-driven high quality administration system, and additional refine its manufacturing technique to scale back prices and shorten lead occasions.

3D Printed Area Rockets

INNOSPACE is amongst a rising variety of corporations leveraging AM to supply important rocket elements. In Might, LEAP 71, a Dubai-based engineering firm, entered a brand new section in its rocket engine program, concentrating on creating meganewton-class propulsion methods. This effort contains two key engine designs: a 200 kN aerospike and a 2000 kN bell-nozzle, each constructed upon earlier work with smaller-scale engines. The corporate is utilizing computational engineering strategies and industrial-scale 3D printing to create complicated propulsion methods tailor-made for future area missions.

In 2023, Australian warmth switch specialist Conflux Know-how partnered with German area rocket producer Rocket Manufacturing facility Augsburg (RFA) to embed their 3D printed warmth exchanger into an orbital rocket. A part of the Australian Area Company’s Moon to Mars initiative, the warmth exchanger elements are 3D printed utilizing Conflux Know-how’s Monel Ok 500 metallic alloy materials and EOS M300-4 Direct Metallic Laser Sintering (DMLS) 3D printers.

Be part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, Area, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

You can too comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

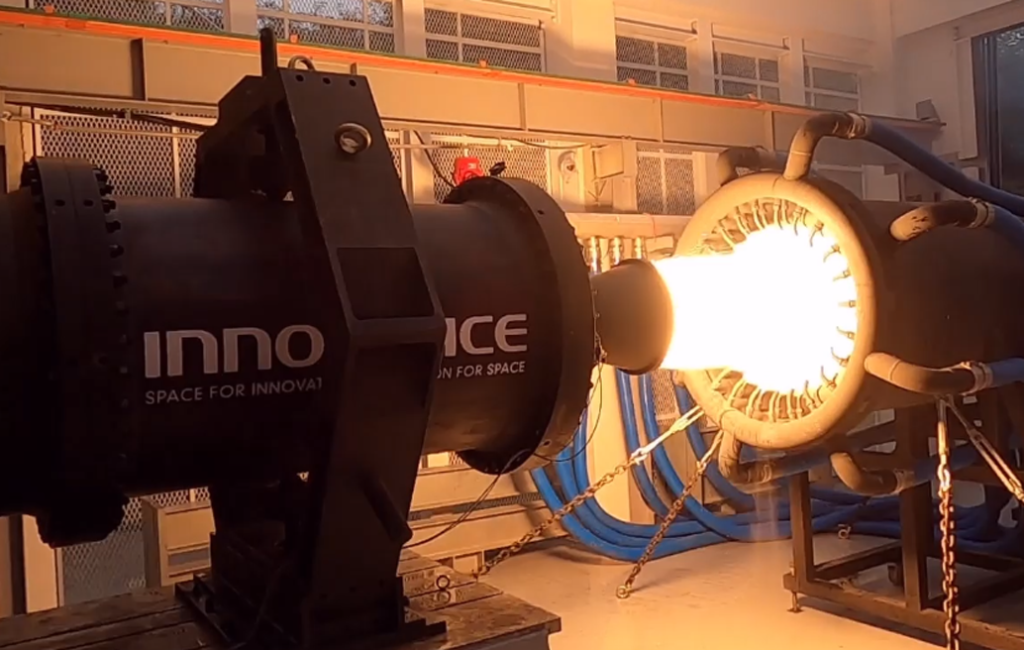

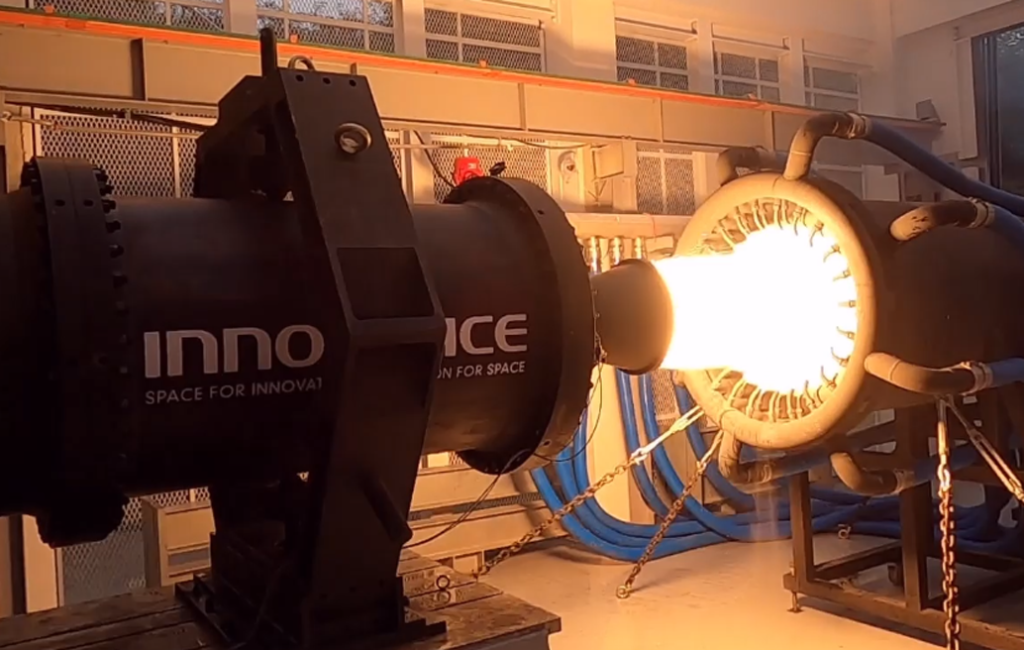

Featured picture exhibits Floor Combustion Check Middle. Picture by way of INNOSPACE.