Superior machine studying mannequin guarantees sooner and extra correct estimation of wear-and-tear, in industrial techniques.

A analysis workforce from the Indian Institute of Science (IISc) and Qatar Science and Know-how Analysis Middle (QSRTC) has created an AI-driven method that may assess corrosion in industrial equipment in energy era techniques with out human intervention. The work was just lately revealed in npj Supplies Degradation.

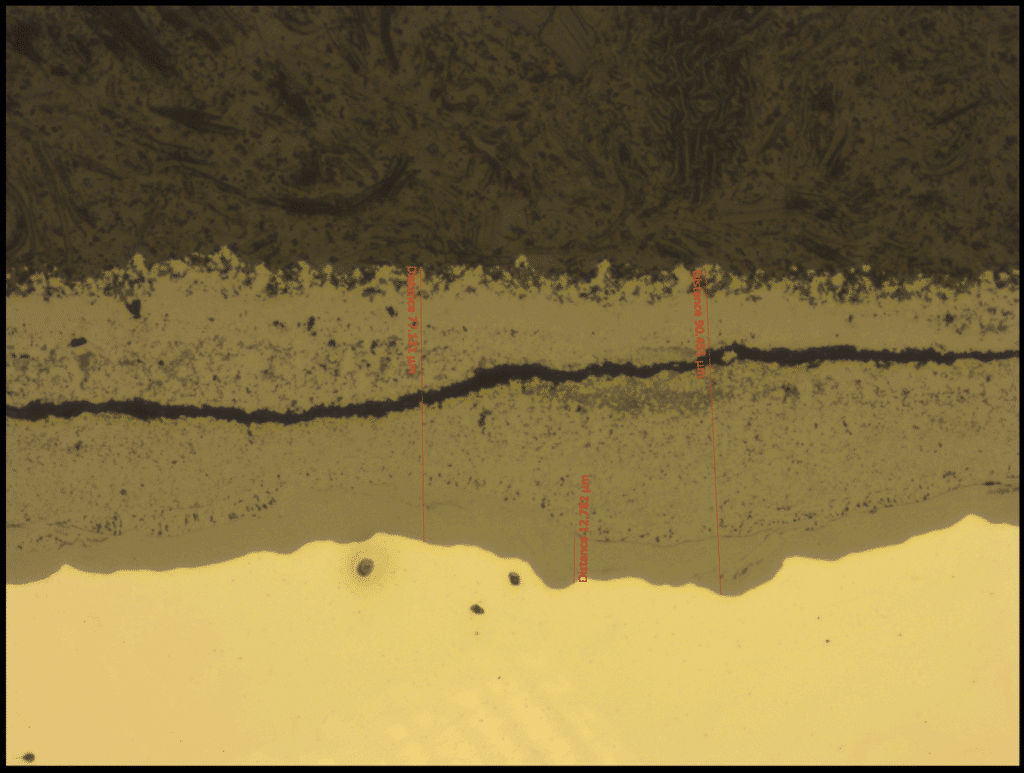

The system makes use of a machine studying algorithm to analyse microscope pictures of corroded metallic surfaces. It estimates corrosion severity by inspecting two key options, thickness of the rust-like deposits and their porosity, or the variety of tiny holes. These bodily properties are linked to the focus of corrosive substances and acidity beneath the deposits.

When corrosion advances, the deposits grow to be thicker, with a corresponding improve in chloride ranges and floor acidity. The workforce discovered that when the native pH drops under a threshold of two.8 to three, the corrosion reaches a sophisticated and damaging stage. This correlation between pH degree and corrosion stage permits the mannequin to function an early warning software.

The algorithm was examined on steam generator tubes, that are vulnerable to under-deposit corrosion in high-temperature industrial settings. It achieved 73% accuracy in figuring out corrosion phases, considerably sooner and extra constant than handbook picture inspection.

In contrast to most machine studying fashions, this method makes use of an unsupervised deep studying method-ok-means clustering to phase microscopy pictures with no need labelled datasets or human-defined classes. This makes it ultimate for analysing advanced and variable corrosion constructions.

The mannequin could be tailored to totally different corrosion sorts however would require fine-tuning for every case. The researchers goal to validate it additional with bigger, extra various datasets. This AI-based technique holds potential to enhance security, cut back upkeep prices, and speed up the digital transformation of business monitoring techniques.