The ferrite cores deal with extra energy, work even when sizzling, and are available in many shapes to be used in vitality, transport, and medical gadgets.

TDK Company has launched a broad vary of latest large-size ferrite cores, providing the business’s widest collection of shapes, sizes, and supplies for such cores. These elements are engineered for considerably elevated energy dealing with, low losses at excessive switching frequencies, and low losses even at elevated temperatures starting from +100 °C to +140 °C. Designed to be used throughout varied industrial functions, these cores assist optimized magnetic efficiency and improved thermal effectivity in programs equivalent to motor drives, EV charging stations, railway and traction programs, energy transformers, welding gear, medical gadgets, uninterruptible energy provides (UPS), photo voltaic inverters, and different renewable vitality applied sciences.

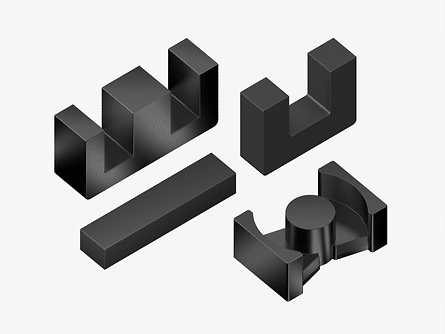

The newly standardized lineup contains well-liked core shapes equivalent to E, U, I, PM, and PQ, and is out there in energy supplies together with N27, N87, N88, N92, N95, and N97. TDK additionally gives important equipment like coil formers—together with variations designed for a number of stacked E-cores—and mounting {hardware} to simplify integration into energy programs.

To assist the design course of, TDK presents the Ferrite Magnetic Design Software freed from cost, serving to engineers simulate and optimize magnetic designs for improved effectivity and thermal habits.

In traction and railway programs, these ferrite cores play a key position in managing excessive energy ranges and making certain environment friendly vitality conversion in difficult circumstances. For electrical automobile (EV) and battery charging infrastructure, the cores ship steady energy switch and thermal stability underneath high-load eventualities.

In renewable vitality functions—together with wind and photo voltaic—they contribute to the dependable and environment friendly operation of energy inverters and associated programs. Vitality storage programs profit from the cores’ means to deal with energy flows effectively throughout each charging and discharging cycles.

In welding programs, the cores preserve steady energy output and assist scale back vitality losses throughout high-frequency operations. Within the medical sector, they’re utilized in varied high-frequency and energy provide gadgets the place efficiency and reliability are crucial.