By Paul Grills, BPF Pipes Group

There’s loads of discuss stopping leaks in under floor water and drainage pipes and the significance of excellent set up; nonetheless, guaranteeing the standard and long-term efficiency of those pipes begins properly earlier than they’re really put in.

British Plastics Federation (BPF) Pipes Group producers make their merchandise to recognised requirements, each for the UK and internationally. In drainage pipes and fittings there are broad styles of choices to select from however the manufacturing course of is a vitally vital a part of guaranteeing these merchandise are match for function.

For instance, in drainage, even non-pressure plastic pipes are examined earlier than they depart the producer.

Most BPF Pipe Group members’ merchandise are third occasion licensed, akin to Kitemark, and stress testing is a part of this. Throughout the take a look at, producers apply as much as 2 levels angular deflection, to permit for the pipe not being put in completely straight/degree, in addition to a diametric distortion take a look at (squeezing the spigot by 10 per cent and the socket by 5 per cent) to ensure it may tolerate some variations in set up.

Not each product will get that take a look at; however the necessities of the European Requirements demand a take a look at each 2-3 years, so plastic pipes are submitted often by pulling out a choice of random samples off the manufacturing line or from inventory. As well as, this testing is repeated any time there’s a change to the fabric or design of the product.

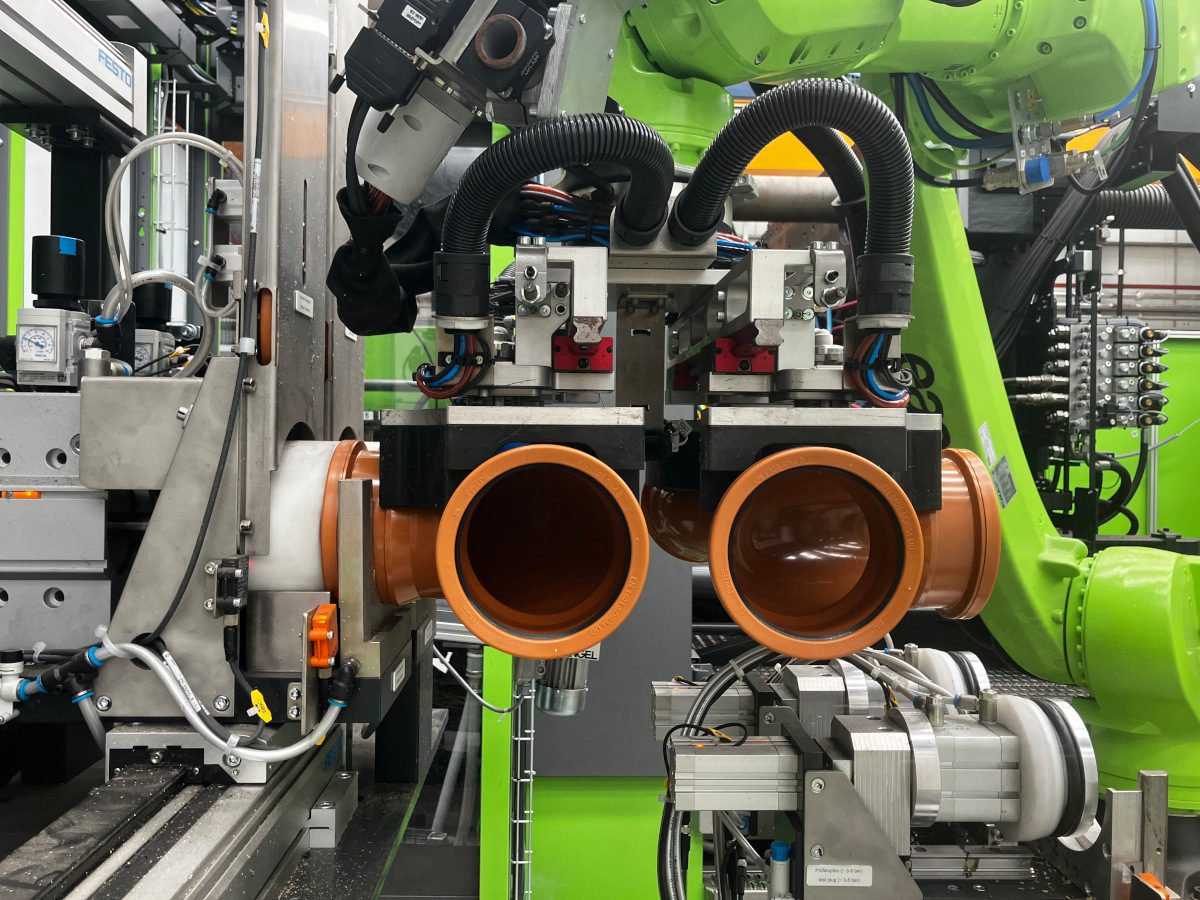

There’s a second half to this testing too: how to make sure that each product leaving the manufacturing unit is to the precise high quality required. For a lot of producers automation is taking part in an more and more vital function in maximising the efficiency and high quality of those merchandise. Through the use of digital camera imaginative and prescient methods to scan the interior and outer dimensions of seals for pipes and fittings made on injection moulding machines, the subtle system is programmed to tug out and reject any that don’t meet the dimensional standards.

So, an instance is 110mm pipe seals. Hundreds are produced and the superior visible inspection system checks each single one. Then a robotic takes this seal and assembles it to the becoming. It then pressurises the becoming for a couple of seconds to make sure leak-tightness. Any rejects are fed again into the recycled product chain so waste is completely minimal.

As soon as the merchandise depart the manufacturing unit and are put in, they need to be air-tested as soon as they’re within the trench earlier than and after backfill, in accordance with Constructing Rules.

The final word intention of the entire course of is for optimum manufacturing with minimal faults or returns. Automation and automatic visible testing are serving to to realize perfection and efficiency in a single – a welcome reassurance, each for the installer and finish person.