The opinions expressed right here by Trellis skilled contributors are their very own, not these of Trellis.

You’ve in all probability heard of the rebound impact — the phenomenon the place financial savings from elevated effectivity (similar to decrease vitality payments) are then spent on different items that finally scale back the anticipated environmental good thing about the unique effectivity efforts.

In your individual life, although, you’ve in all probability seen that it doesn’t must work this manner. Perhaps you’ve put aside the cash saved from reducing your vitality payments by upgrading to sensible thermostats or different sustainable residence initiatives, similar to putting in extra environment friendly home equipment. These financial savings can operate as capital for different enhancements, and, in flip, snowball into extra financial savings.

Sustainable packaging is approaching an analogous alternative for financial savings. Proper now, seven states are about to mandate packaging charges by means of prolonged producer duty (EPR) applications. Beneath EPR applications, supplies — and their charges — aren’t created equal. These applications use a method referred to as eco-modulation to primarily grade supplies on a curve: the decrease the environmental affect, the decrease the charge for producers. In follow, this implies versatile plastic, for instance, usually has greater charges than extra simply recycled supplies.

As these applications launch in these states and doubtlessly advance to others, corporations can unlock a brand new alternative to avoid wasting on charges, after which reinvest the financial savings again into extra sustainable packaging choices. Name it “enchancment capital” for lower-carbon supplies, extra assortment applications and smarter sortation know-how.

Potential financial savings for lower-impact supplies

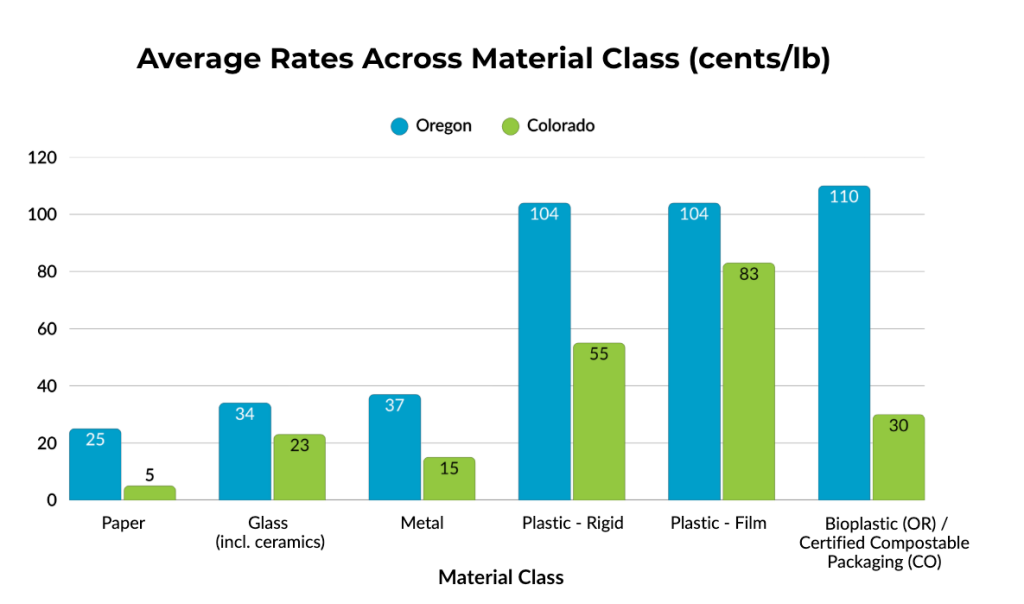

We discover the primary steps of enchancment capital in Oregon and Colorado, the primary to publish the charges that packaging producers shall be charged for a variety of packaging supplies similar to glass, aluminum, inflexible plastic, versatile plastic and compostable packaging.

To take a look at broad traits, it helps to mix the wide selection of supplies lined underneath these legal guidelines into just a few choose classes and to common the charges per class. For instance, the charges for inflexible plastic range from 17 cents/lb for PET plastic (utilized in packaging similar to water bottles) in Oregon to 171 cents/lb for “inflexible different” in Colorado.

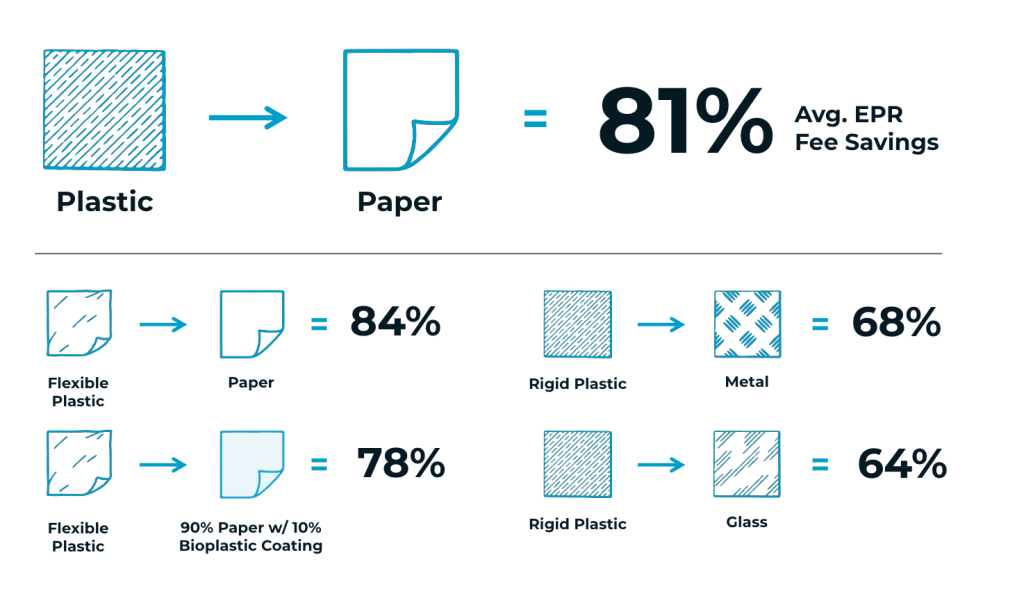

Trying on the common charges in Oregon and Colorado, we see that shifting from inflexible plastic to paper is a roughly 81 p.c charge financial savings. Shifting from inflexible plastic to steel or glass provides corporations financial savings within the 60 p.c vary, and shifting from versatile plastic right into a paper bundle with a bioplastic coating yields roughly 78 p.c in financial savings. The takeaway? Corporations may see substantial financial savings from switching to totally different supplies — and these switches are bolstered by shopper perceptions about which supplies are extra sustainable.

What may these financial savings seem like for a typical firm? To reply that query, think about this:

- A shopper packaged items model is planning a swap from 34,000 tons of versatile plastic packaging to a paper choice

- The model does about 19 p.c of their U.S. gross sales in EPR states with charges

- This new packaging choice would require a 16 p.c improve in materials utilization

On this state of affairs, the financial savings are vital: $11 million in charges saved throughout the seven EPR states. In fact, these financial savings will rely on a mess of things, and the price of switching to a brand new materials must be factored in. However even when another similar to paper is dearer, innovation can result in financial savings. Extra back-of-the-envelope calculations present that on this case, a 34 p.c improve in materials prices would nonetheless result in over $600,000 in internet financial savings. These are simply pattern calculations, however the take-home message is evident. Strategically switching to lower-fee supplies can add as much as significant financial savings.

Redeploying financial savings

Proper now, EPR charges are seemingly going to return out of 1 a part of a corporation’s finances and investments in sustainability, new know-how, and R&D are coming from one other. However what if there may very well be some suggestions mechanisms between the 2?

It is going to take collaboration and shared objectives between finance, product and sustainability groups, however as soon as the connection between charges and innovation has been established, you’ll have much more highly effective incentives to construct sustainability into your finances.

That is when the thrilling sustainability work begins. The financial savings from prevented charges may very well be used as a technique to cowl further R&D and fund extra testing into how nicely packages are being reprocessed at materials restoration services, paper mills and composting services. The financial savings is also redirected again into shopper training campaigns, particularly round subjects similar to retailer drop-off the place we all know customers are confused and wish extra info.

Charges is usually a driver of innovation

Proper now, the packaging business has the chance to see charges as attainable new funding capital. Corporations can lower your expenses by switching to incentivized, lower-fee supplies and packaging codecs. Then, they will reinvest these financial savings again into the sustainable supplies that after appeared out of attain.

Your organization can get began by:

- Cross reference the supplies in your packaging portfolio with the bottom charges and dues posted for Colorado and Oregon, two states which have posted early charge projections

- Calculate the biggest liabilities in your present portfolio, then run back-of-the-envelope calculations on the potential advantages of switching into lower-fee materials classes

- Discover out how one can make sustainable switches or work with packaging consultancies to help sustainable transformations

Identical to the financial savings from decrease vitality payments will be directed in the direction of different sustainable residence initiatives, the financial savings in EPR charges will be funneled in the direction of strategic improvements in supplies and recycling infrastructure.

With EPR legal guidelines in seven states, the packaging business has the chance to reverse the rebound impact by turning charges into momentum wanted to energy sustainable packaging’s innovation flywheel.