The cobbled streets and centuries-old college halls of Leuven lately served as a picturesque backdrop for the Materialise 3D Printing in Hospitals Discussion board 2025. Belgium’s Flemish Brabant capital hosted the annual assembly, which has turn into a key gathering for the medical 3D printing neighborhood since its launch in 2017.

This 12 months, 140 worldwide healthcare professionals convened for 2 days of talks, workshops, and energetic dialogue on how Materialise’s software program enhances affected person care. The Discussion board’s opening day, hosted at Leuven’s historic Irish Faculty, featured 16 displays by 18 healthcare clinicians and medical 3D printing consultants.

Whereas typically described as the way forward for medication, customized healthcare has already turn into routine in lots of medical settings. Audio system emphasised that 3D printing is now not merely a “cool” innovation, however an important software that improves affected person outcomes. “Personalised therapy is not only a imaginative and prescient for the long run,” mentioned Koen Peters, Government Vice President Medical at Materialise. “It’s a actuality we’re constructing collectively day by day.”

In the course of the discussion board, practitioners and medical engineers demonstrated the crucial function of Materialise’s software program in medical workflows. Displays highlighted worth throughout a variety of procedures, from mind tumour removing and organ transplantation to the separation of conjoined twins and maxillofacial implant surgical procedures. A number of use circumstances demonstrated how 3D know-how can cut back surgical procedure instances by as much as 4 instances, improve affected person restoration, and lower hospital prices by nearly £6,000 per case.

Digital simulation and 3D printing slash working instances

Headquartered just a few miles exterior Leuven’s medieval middle, Materialise is a worldwide chief in medical 3D printing and digital planning. Its Mimics software program suite mechanically converts CT and MRI scans into detailed 3D fashions. Clinicians use these instruments to organize for procedures, analyse anatomy, and create patient-specific fashions that improve surgical planning.

Up to now, Materialise software program has supported greater than 500,000 sufferers and analysed over 6 million medical scans. One case that generated notable curiosity among the many Discussion board’s attendees was that of Lisa Ferrie and Jiten Parmar from Leeds Basic Infirmary. The pair labored alongside Asim Sheikh, a Advisor Skullbase and Neurovascular Neurosurgeon, to conduct the UK’s first “coach door osteotomy” on Ruvimbo Kaviya, a 40-year-old nurse from Leeds.

This novel keyhole surgical procedure efficiently eliminated a mind tumor from Kaviya’s cavernous sinus, a hard-to-reach space behind the eyes. Most surgical procedures of this type require giant incisions and the removing of considerable cranium sections, leading to prolonged restoration time and the danger of postoperative issues. Such an method would have introduced critical dangers for eradicating Kaviya’s tumor, which “was in a posh space surrounded by a variety of nerves,” defined Parmar, a Advisor in Maxillofacial Surgical procedure.

As a substitute, the Leeds-based group makes use of a minimally invasive approach that requires solely a 1.5 cm incision close to the facet of Ravimbo’s eyelid. A small part of cranium bone was then shifted sideways and backward, very similar to a coach door sliding open, to create an entry level for tumor removing. Following the process, Ravimbo recovered in a matter of days and was left with solely a 6 mm scar on the incision level.

Materialise software program performed a significant function in facilitating this novel process. Ferrie is a Biomedical Engineer and 3D Planning Service Lead at Leeds Instructing Hospitals NHS Belief. She used mimics to transform medical scans into digital 3D fashions of Ravimbo’s cranium. This allowed her group to conduct “digital surgical planning” and observe the process in three dimensions, “to see if it’s going to work as we anticipate.”

Ferrie additionally fabricated life-sized, polyjet 3D printed anatomical fashions of Ravimbo’s cranium for extra hands-on surgical preparation. Sheikh and Parmar used these fashions within the hospital’s cadaver lab to rehearse the process till they have been assured of a profitable consequence. This 3D printing-enabled method has since been repeated for extra circumstances, unlocking a brand new normal of look after sufferers with beforehand inoperable mind tumors.

The impression of 3D planning is hanging. Common working instances fell from 8-12 hours to only 2-3 hours, and common affected person discharge instances dropped from 7-10 days to 2-3 days. These efficiencies translated into price financial savings of £1,780 to £5,758 per case, whereas further surgical capability generated a mean of £11,226 in revenue per working listing.

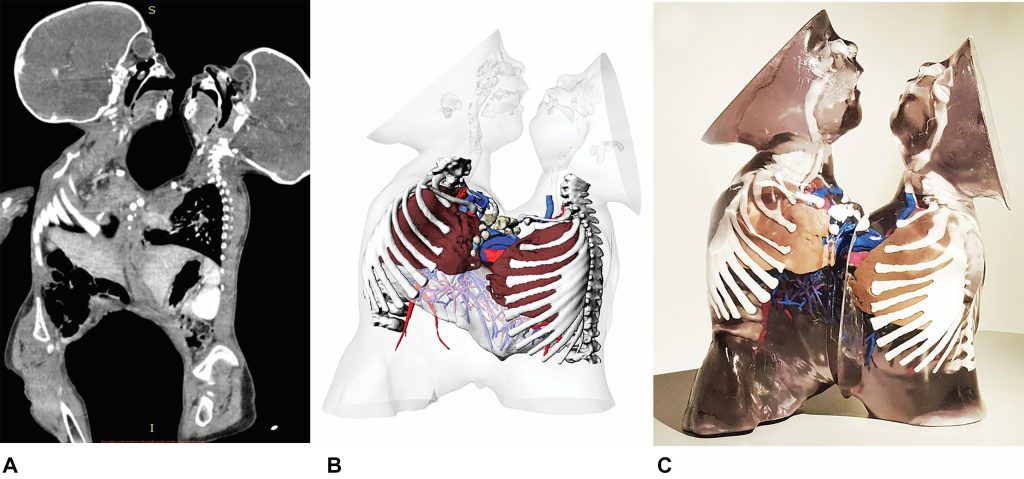

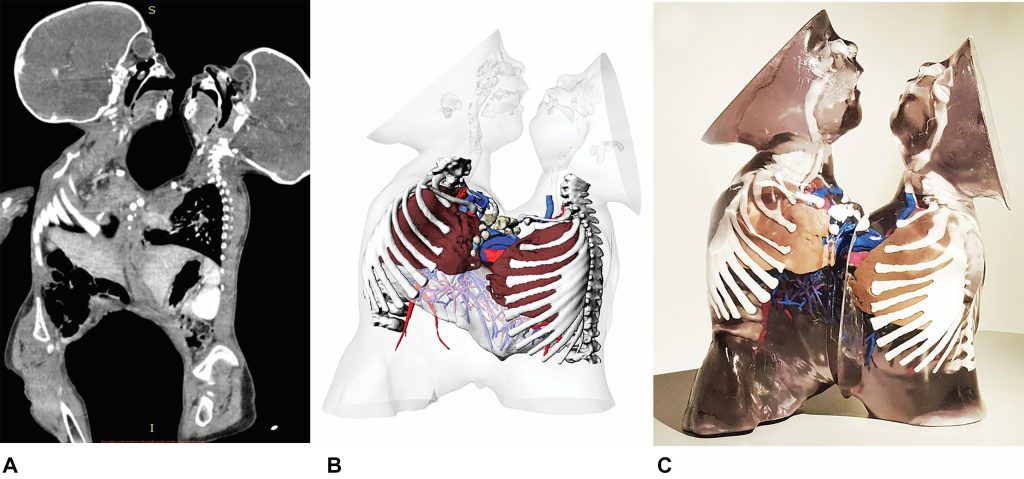

Dr. Davide Curione additionally mentioned the worth of digital planning and 3D printing for surgical procedures. Based mostly at Bambino Gesù Pediatric Hospital in Rome, the radiologist’s group conducts 3D modeling, visualization, simulation, and 3D printing.

One case concerned thoraco-omphalopagus twins joined on the chest and stomach. Curione’s group 3D printed a multi-color anatomical mannequin of the twins’ anatomy, which he known as “the primary of its type for complexity in Italy.” Fabricated in clear resin, the mannequin supplied an in depth view of the twins’ inside anatomy, together with the rib cage, lungs, and cardiovascular system.

Consideration then turned to the liver. The group constructed a digital reconstruction to simulate the optimum resection planes for the overall separation and the hepatic splitting process. This was adopted by a second multi-colour 3D printed mannequin highlighting the organ’s vascularisation. These sources improved surgical planning, chopping working time by 30%, and enabled a profitable separation, with no main issues reported two years post-operation.

VR-enabled surgical procedure enhances organ transplants

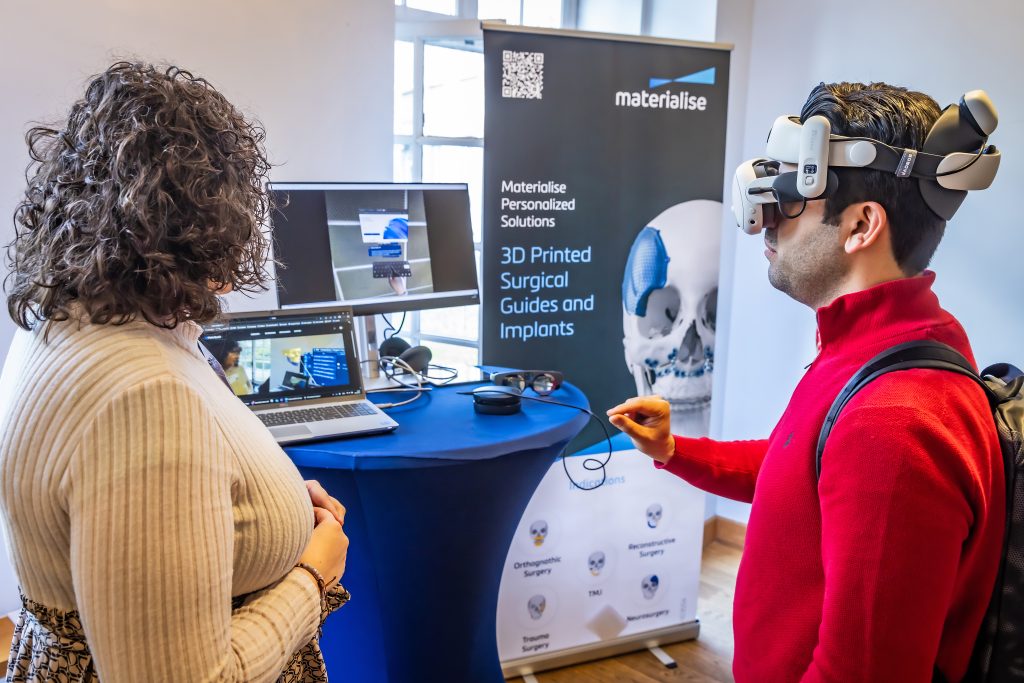

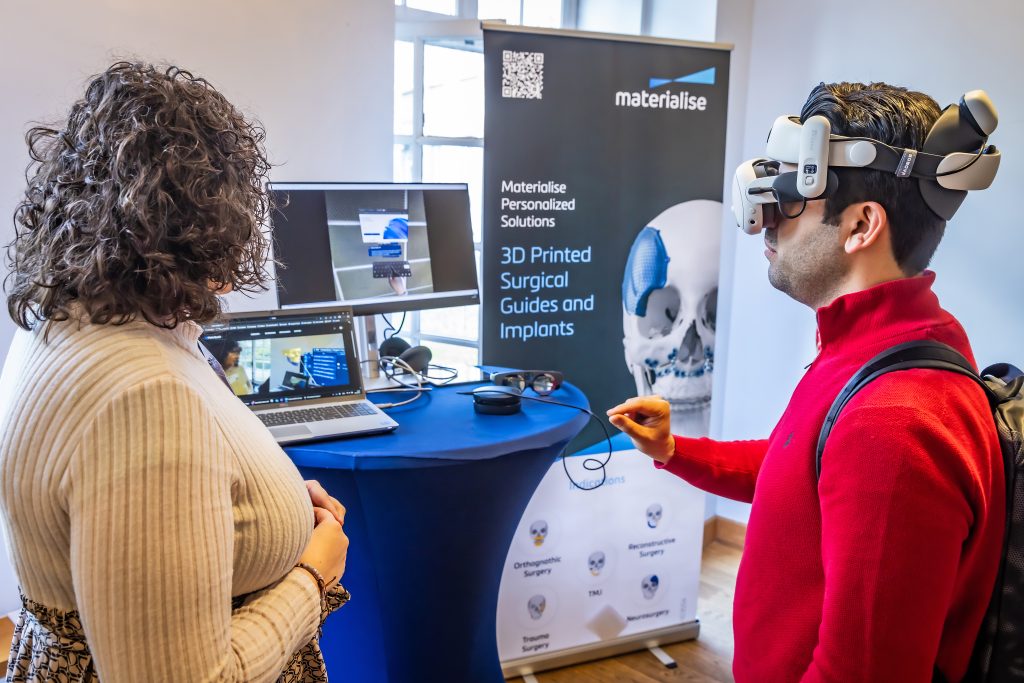

Materialise’s Mimics software program will also be utilized in prolonged actuality (XR), permitting clinicians to work together extra intuitively with 3D anatomical fashions and medical photos. By utilizing off-the-shelf digital actuality (VR) and augmented actuality (AR) headsets, healthcare professionals can extra intently look at advanced buildings in an immersive setting.

Dr. David Sibřina is a Principal Researcher and Developer for the VRLab group at Prague’s Institute for Scientific and Experimental Medication (IKEM). He leads efforts to speed up the medical adoption of VR and AR in organ transplantation, surgical planning, and surgical steerage.

The previous Forbes 30 Underneath 30 honouree defined that since 2016, IKEM’s 3D printing lab has centered on producing anatomical fashions to assist liver and kidney donor programmes. His lab additionally fabricates 3D printed anatomical fashions of ventricles and aneurysms for medical use.

Nonetheless, Sibřina’s group lately grew to become overwhelmed by excessive demand for bodily fashions, with surgeons requesting further 3D mannequin processing choices. This led Sibřina to create the IKEM VRLab, providing XR capabilities to assist surgeons plan and conduct advanced transplantation surgical procedures and resection procedures.

When turning to XR, Sibřina’s lab opted towards adopting a ready-made software program resolution, as an alternative growing its personal from scratch. “The issue with a number of the business options is functionality and integration,” he defined. “The units are extremely tough and costly to combine inside medical techniques, notably in public hospitals.” He additionally pointed to consumer interface shortcomings and the shortage of alignment with established medical protocols.

In accordance with Sibřina, IKEM VRLab’s providing is a flexible and scalable VR system that’s easy to make use of and customizable to completely different surgical disciplines. He described it as “Zoom for 3D planning,” enabling reside digital collaboration between medical professionals. It leverages joint CT and MRI acquisition fashions, developed with IKEM’s medical physicists and radiologists. Knowledge from affected person scans is transformed into interactive digital reconstructions that may be leveraged for evaluation and surgical planning.

IKEM VRLab additionally presents a digital “Becoming Room,” which permits surgeons to evaluate whether or not a donor’s organ dimension matches the recipient’s physique. A digital mannequin is created for each deceased donor and reside recipient’s physique, enabling surgeons to carry out the dimensions allocation assessments.

Sibřina defined that this functionality considerably reduces the variety of recipients who would in any other case fail to be matched with an appropriate donor. For instance, 262 deceased liver donors have been processed for Becoming Room dimension allocations by IKEM VRLab. In 27 situations, the VR Becoming Room prevented potential recipients from being skipped within the ready listing primarily based on normal biometrics, CT axis measurements, and BMI ratios.

Total, 941 patient-specific visualizations have been carried out utilizing Sibřina’s know-how. 285 (28%) have been for liver recipients, 311 (31%) for liver donors, and 299 (23%) for liver resection. Dwelling liver donors account for 59 (6%) circumstances, and cut up/decreased donors for 21 (2%).

Personalised healthcare: 3D printing implants and surgical guides

Past surgical planning and 3D visualisation, Materialise Mimics software program helps the design and manufacturing of patient-specific implants and surgical guides. The corporate conducts healthcare contract manufacturing at its Leuven HQ and medical 3D printing facility in Plymouth, Michigan.

Hospitals can design patient-specific medical units in-house or collaborate with Materialise’s medical engineers to develop customized elements. Materialise then 3D prints these units and ships them for medical use. The Belgian firm, headed by CEO Brigitte de Vet-Veithen, produces round 280,000 customized medical devices every year, with 160,000 destined for the US market. These embrace personalised titanium cranio-maxillofacial (CMF) implants for facial reconstruction and colour-coded surgical guides.

Poole Hospital’s 3D specialists, Sian Campbell and Poppy Taylor-Crawford, shared how their group has adopted Materialise software program to assist advanced CMF surgical procedures. Since buying the platform in 2022, they’ve developed digital workflows for planning and 3D printing patient-specific implants and surgical guides in 14 circumstances, notably for facial reconstruction.

Campbell and Taylor-Crawford start their workflow by importing affected person CT and MRI knowledge into Materialise’s Mimics Enlight CMF software program. Automated instruments deal with preliminary segmentation, tumour resection planning, and the creation of chopping planes. For extra advanced circumstances involving fibula or scapula grafts, the group adapts these workflows to make sure exact alignment and match of the bone graft throughout the defect.

Subsequent, the surgical plan and anatomical knowledge are transferred to Materialise 3-matic, the place the group designs patient-specific resection guides, reconstruction plates, and implants. These designs are refined by shut collaboration with surgeons, incorporating suggestions to optimise geometry and match. Digital match checks confirm information accuracy, whereas additional evaluation ensures compatibility with surgical devices and working constraints. As soon as validated, the guides and implants are 3D printed for surgical procedure.

In accordance with Campbell and Taylor-Crawford, these customized units allow extra correct resections and implant placements. This improves surgical alignment and reduces theatre time by minimising intraoperative changes.

Customized 3D printed implants are additionally fabricated on the Rizzoli Orthopaedic Institute in Bologna, Italy. Initially established as a movement evaluation lab, the institute has expanded its experience into surgical planning, biomechanical evaluation, and now, customized 3D printed implant design.

Dr. Alberto Leardini, Director of the Motion Evaluation Laboratory, described his group’s patient-specific implant workflow. They mix CT and MRI scans to establish bone defects and tumour areas. Scientific engineers then use this knowledge to construct digital fashions and plan resections. Additionally they design chopping guides and customized implants tailor-made to every affected person’s anatomy.

These designs are refined in collaboration with surgeons earlier than being outsourced to manufacturing companions for manufacturing. Importantly, this workflow internalizes design and planning phases. By internet hosting engineering and medical groups collectively on-site, they goal to streamline decision-making and cut back lead instances. As soon as the digital design is finalised, solely the additive manufacturing step is outsourced, making certain “zero distance” collaboration between groups.

Dr. Leardini emphasised that this method improves medical outcomes and guarantees financial advantages. Whereas customized implants require extra imaging and upfront planning, they cut back time within the working theatre, shorten hospital stays, and minimise affected person transfers.

After a full day of displays contained in the Irish Faculty’s eighteenth-century chapel, the consensus was clear. 3D know-how will not be a distinct segment functionality reserved for high-end procedures, however a priceless software enhancing on a regular basis look after 1000’s of sufferers globally. From quicker surgical procedures to price financial savings and customized remedies, hospitals are more and more embedding 3D know-how into routine care. Materialise’s software program sits on the coronary heart of this shift, enabling clinicians to ship safer, smarter, and extra environment friendly healthcare.

Take the 3DPI Reader Survey – form the way forward for AM reporting in beneath 5 minutes.

Learn all of the 3D printing information from RAPID + TCT 2025

Subscribe to the 3D Printing Business publication to maintain up with the most recent 3D printing information.

You can even observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals 3D printed anatomical fashions at Materialise HQ in Leuven. Picture by 3D Printing Business.