Because the world strikes in direction of its formidable local weather pleasant purpose of net-zero emissions by 2050, transport sector, which contributes between 15% to 25% of complete international GHG emissions in accordance with various estimates, might be carefully monitored. Transition from ICE automobiles to Electrical Automobiles (EVs) on a big scale is crucial on this regard.

The Worldwide Vitality Company (IEA), in its not too long ago launched report ‘World EV Outlook 2025’ estimated that globally, EV gross sales crossed 17 million in 2024, reaching a gross sales share of greater than 20% of complete automotives offered. With China main the best way amounting to half of world electrical gross sales, and new markets rising in Asia and Latin America, electrical vehicles are anticipated to exceed a share of 40% of complete share by 2030 beneath present coverage settings.

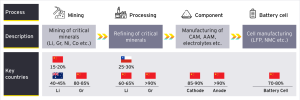

Together with progress in EV gross sales, the demand for batteries have additionally gone up, accounting for 950GWh in 2024. The battery makes up about 40% of an EV’s complete value, with lithium as the primary component in most batteries worldwide. A Lithium-ion battery (LIB) is made up of a graphite anode, with lithium salt because the electrolyte and a cathode consisting of Lithium compounded with Nickel, Cobalt or Manganese. Consequently, typical lithium-ion batteries are generally known as NMC batteries, denoting their composition of nickel, manganese, and cobalt.

Provide Chain imbalances of LIBs:

Whereas reserves of those minerals are current in a broad geography of Latin America, Australia, Africa and others, the down stream provide chain of processing and battery manufacturing is closely skewed in favour of China.

EY analysis reveals China’s maintain over processing of EV parts encompasses 80-90% of world share. On the similar time with giants like CATL, China homes over 70-80% of world LIB manufacturing. Over time these giants have innovated and decreased using Nickel and Cobalt in LIBs and produced Lithium iron phosphate (LFP) batteries on a big scale.

NMC batteries, that are nonetheless prevalent within the US and Europe present an power density benefit over the LFP batteries, that are in flip cheaper and are extensively utilized in China. The power density of LFP battery packs is about one-fifth decrease by mass (Wh/kg) and one-third decrease by quantity (Wh/L) than that of NMC battery packs. This benefit, nevertheless, is partly offset by LFP’s functionality to achieve 100% state of cost when required with out important degradation, whereas NMC batteries are usually restricted to 80% to protect long-term efficiency. The NMC batteries are most popular for working in colder climates and over lengthy ranges. Whereas enhanced efficiency degree of LFP batteries and the given value benefits have made them widespread within the mass markets.

World Lithium Constraints:

Primarily Lithium, usually referred as ‘white gold’ is extracted from two sources throughout the globe. Firstly, there are minerals like spodumene, petalite, and lepidolite and secondly from Lithium salts like Lithium hydroxide, Li carbonates and Li chlorides that are extremely accessible in lakes throughout the Andes mountains.

Elements of Argentina, Bolivia and Chile type the Lithium triangle with massive proportion of world’s Lithium reserves. Nonetheless, an nationalization drive over these reserves appears to proliferate within the Latin American nations, akin to what passed off vis-à-vis oil sector with the formation of OPEC within the Sixties introducing new complexities on international provide chains.

Then there’s additionally analysis happening Absorption kind aluminium based mostly direct Lithium extraction, which may cut back water drainage, however such strategies are at low Technical Readiness ranges (TRL)

Discovering a method across the ‘White Gold’:

These dynamics have compelled governments and automakers to take a look at options to Lithium. A number of the alternate EV battery applied sciences thought of are as follows:

| Battery Know-how | Anode Energetic Materials (AAM) | Cathode Energetic Materials (CAM) | Electrolyte |

| Sodium Ion Battery (SIB) | Exhausting in addition to mushy Carbon simply accessible from Crop residue or Agri waste | Sodium ions comparable to layered oxides | Salts comparable to sodium hexafluorophosphate (NapF6) |

| Zinc manganese Dioxide battery | Zinc metallic, 80% of which globally accessible is from recycled merchandise | Oxygen from air | Aqueous answer of Potassium hydroxide

(KOH) |

| Aluminium-Air battery | Stable Aluminium metallic | Oxygen from air | Excessive pH answer of KOH, NaOH and even NaCl. |

| Hydrogen Gas Cell (HFC) | Hydrogen fuel | Oxygen from air | KOH or NaOH |

The metals apart from Lithium which can be largely utilized in metallic ion or metallic air batteries are extensively accessible however TRLs of 7-9 as required for industrial EVs are but not achievable with these applied sciences. Nonetheless, applied sciences like Al-air batteries are inducted in different functions like medical units. Metallic air batteries have increased power density and decrease value than LIBs however have persistent design challenges.

Batteries with strong electrolytes referred to as strong state batteries are regarded upon with excessive optimism even with low TRLs. Electrolytes utilized in them are largely oxides, sulphides or polymer electrolytes.

Whereas HFCs are in use commercially, however their manufacturing strategies stay debatable. Manufacturing of hydrogen by electrolysis of water referred to as inexperienced hydrogen remains to be restricted in comparison with blue hydrogen (produced from methane) and gray hydrogen (produced from capturing hydrogen from fossil gas).

Lowering Dependence by Recycling

A significant supply of Uncooked materials extraction is City mining, which entails extracting helpful supplies from E-Waste contributing to a round financial system. In line with World E-waste monitor, we’d see E-waste manufacturing ranges of 82 million tonnes globally by 2030 offering big recycling potential. Though inefficient recycling mechanisms hinder city mining potential. A scientific strategy of gathering, sorting and dismantling E-waste adopted by strategies like Pyrometallurgy (Smelting), Hydrometallurgy (Chemical separation) and Biometallurgy (Organic separation) should be built-in at floor degree.

It’s to be remarked that Various battery options received’t cut back the share of LIBs and LFPs in EVs instantly simply as EVs received’t out of the blue exchange ICEs on roads. A coordinated technique engaged on typical sources whereas constructing resilience by options is the necessity of the hour for a simply local weather transition.