The approach avoids poisonous byproducts from standard halogen gases, chopping environmental impression whereas advancing semiconductor scaling.

Researchers from Japan and Taiwan have demonstrated a halogen-free plasma approach able to etching hafnium oxide (HfO2) movies with atomic-level precision, marking a major step for next-generation semiconductor manufacturing. Reported in Small Science, the method achieves clean, uniform surfaces at room temperature with out counting on poisonous halogen-based gases, that are extensively utilized in standard plasma etching.

HfO2 is already a cornerstone materials in superior electronics, valued for its excessive dielectric fixed, thermal stability, and large band hole. These properties make it a vital candidate for ultrathin gate insulators in 2D transistors and next-gen reminiscence gadgets. But its robust hafnium–oxygen bonds additionally make HfO2 notoriously troublesome to etch with each precision and floor smoothness.

Conventional plasma-enhanced atomic layer etching (ALE) strategies deal with this utilizing halogen gases—sometimes fluorine or chlorine—mixed with energetic ion bombardment. Whereas efficient, the method has drawbacks. Halogen gases are poisonous and environmentally damaging, whereas their byproducts usually have low volatility, clinging to reactor partitions or machine sidewalls and degrading efficiency.

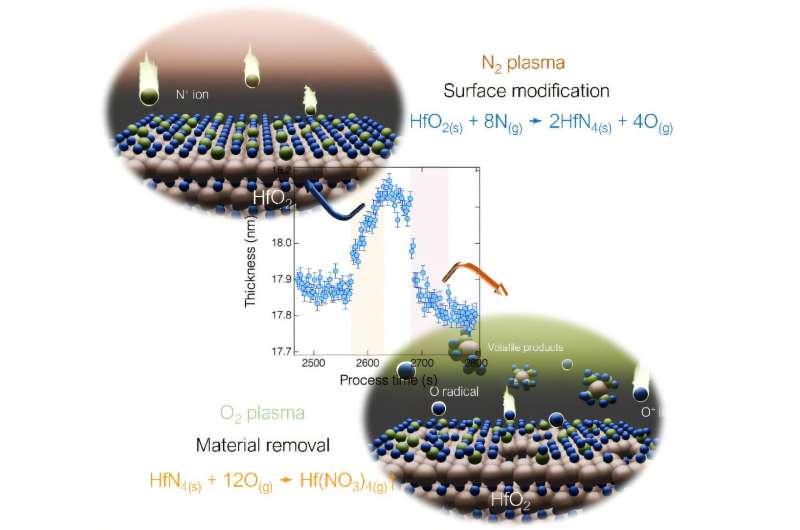

The group, led by Nagoya College’s Shih-Nan Hsiao and Masaru Hori in collaboration with Ming Chi College of Expertise, designed a two-step cyclic technique that replaces halogens with nitrogen and oxygen plasmas. Within the first stage, N⁺ ions bombard the HfO2 floor, bonding nitrogen to the movie. Within the second, an O2 plasma strips away the nitrogen-bonded layer through a self-limiting response. Every cycle removes simply 0.023 to 0.107 nanometers of fabric, enabling subatomic precision.

Floor evaluation utilizing infrared spectroscopy and X-ray photoelectron spectroscopy confirmed that nitrogen atoms briefly substitute oxygen atoms through the cycle earlier than decomposing into unstable byproducts underneath oxygen plasma. Past etching, the tactic additionally improves floor morphology: after 20 cycles, roughness was diminished by 60%.

Crucially, the method operates at room temperature, saving power and simplifying integration into semiconductor fabs. It additionally avoids halogen-based residues, supporting cleaner, extra sustainable manufacturing.

As semiconductor dimensions shrink to just some nanometers, methods like this will probably be important to keep up machine efficiency whereas decreasing environmental impression. The examine establishes the primary halogen-free atomic-level etching route for HfO2, doubtlessly setting a mannequin for processing different hard-to-etch supplies in superior microelectronics.