Researchers at POSTECH have developed a dry adhesive utilizing form reminiscence polymers that permits exact pick-and-place of micro-LEDs and on a regular basis supplies—with out glue or residue, this might rework show manufacturing and good meeting programs.

A analysis staff from Pohang College of Science and Know-how (POSTECH) has launched a dry adhesive expertise that permits simple attachment and detachment of a variety of supplies—from microscale digital parts to on a regular basis objects like paper or cloth. This work was rwas led by Professor Seok Kim in collaboration with scientists from POSTECH, Gachon College, Chonbuk Nationwide College, and the College of Connecticut.

The core motivation for the analysis got here from the manufacturing challenges of micro-LEDs, a next-generation show expertise recognized for its brightness, flexibility, and sturdiness. Micro-LED chips are extremely tiny—smaller than a human hair—and transferring them to show panels with accuracy has been a serious impediment. Conventional strategies utilizing moist adhesives or switch movies typically lead to poor alignment, contamination, and sophisticated steps.

The researchers tackled a recognized concern in floor science referred to as the “adhesion paradox,” the place robust atomic-level adhesion is predicted in idea, however in apply, floor roughness prevents robust contact. The staff flipped this limitation into a bonus.

Their innovation makes use of form reminiscence polymers (SMPs) embedded with nano-sized suggestions. At regular temperatures, the fabric’s tough floor results in low stickiness. However when heated and pressed, the floor smooths out—much like ironing garments—permitting it to strongly adhere to things. Upon reheating, the fabric regains its tough texture, releasing the thing effortlessly.

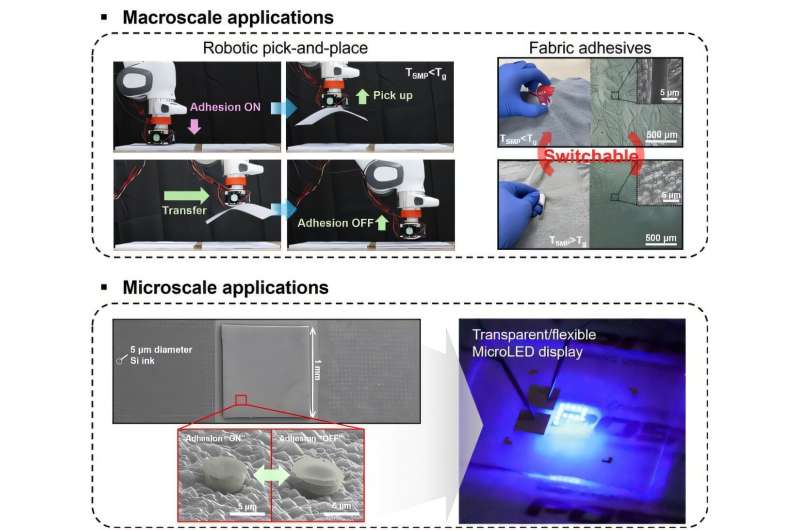

This reversible bonding mechanism delivers highly effective adhesion (over 15 atmospheres) when engaged and practically zero power when disengaged. In demonstrations, micro-LEDs have been picked and positioned exactly by a robotic arm, and the adhesive labored simply as properly on mushy supplies like paper or cloth.

“This expertise permits ultra-precise dealing with of delicate parts with out sticky residues,” stated Professor Seok Kim. The researchers consider it could possibly revolutionize industries like show manufacturing and semiconductor meeting, particularly as good manufacturing continues to evolve.