Additive manufacturing has turn out to be a key pillar of the UK Ministry of Defence’s (MoD) technique to strengthen Britain’s warfighting edge. This was mirrored at TCT 3Sixty 2025, Britain’s largest 3D printing commerce present.

Because the Birmingham NEC’s Corridor 3 opened to the present ground final week, the MoD’s AM-focused Mission TAMPA convened in an adjoining convention house for its second working group assembly of the yr. The TCT Insights stage additionally featured shows and panel discussions from MoD specialists and protection primes, together with Leonardo and Thales.

Additive Manufacturing Benefit: Aerospace, Area and Protection returns on July tenth. Reserve your free ticket now.

Talking on the TCT present, Wing Commander Jon McMahon supplied insights into the MoD’s imaginative and prescient for superior manufacturing. The MoD Defence Help Innovation Group’s Deputy Group Chief characterised 3D printing as a significant instrument for diversifying protection provide chains in a “manufacturing facility to foxhole” strategy. Mission TAMPA, he added, is essential to profitable “hearts and minds,” changing skeptics, and growing AM adoption within the protection sector.

Based on the previous RAF Flight Simulator Technician, Mission TAMPA can ship £118 million in advantages for a price of £6–7 million over the subsequent 5 years. He additionally highlighted its function in enhancing tools uptime on the battlefield, describing expeditionary 3D printers as “one other instrument in our arsenal” to get essential navy tools “again within the combat.”

In the end, McMahon emphasised that constructing belief and forging new partnerships between Protection and business is essential to enhancing Britain’s warfighting capabilities. Success, he argued, will rely not solely on proving technical functionality however on embedding a completely digital, agile provide chain that may meet operational wants at pace and scale.

The MoD’s additive manufacturing technique

Earlier this yr, the MoD revealed its first Defence Superior Manufacturing Technique, which prioritizes 3D printing as a key know-how to be “embraced” within the UK’s protection provide chain.

Extra lately, the Authorities launched the 2025 Strategic Defence Assessment. With out explicitly mentioning 3D printing, it highlights the necessity to improve warfighting readiness via superior manufacturing. The plan features a £1.5 billion funding in an ‘always-on’ munitions pipeline, £400 million in funding for British firms. It additionally incorporates a dedication to provide 7,000 new long-range weapons, as much as 12 new nuclear-powered assault submarines, and continued assist for the 3D printing-enabled GCAP programme.

These initiatives intention to create a diversified provide chain constructed round a community of amenities that mix superior and traditional manufacturing. “Superior manufacturing isn’t a silver bullet,” McMahon acknowledged. “It won’t be the reply to each drawback.” Nonetheless, the MoD’s “manufacturing facility to foxhole” technique spans each stage of defence of the protection ecosystem, from supplying spare elements on the entrance strains to constructing next-generation nuclear submarines.

In submarine manufacturing, 3D printing has turn out to be essential, unlocking the fabrication of parts that typical strategies can’t produce. As McMahon famous, additive manufacturing delivers a “game-changing” operational benefit by chopping lead instances and boosting resilience. Certainly, present provide networks and obsolescent elements can go away fight tools sidelined for months. Additive manufacturing presents a solution to bypass these bottlenecks.

This worth is shifting procurement considering in direction of a mindset not seen because the Chilly Conflict. “For the final 30 years, we’ve been a bottom-line centered organisation,” McMahon stated. “We are actually attempting to vary that mindset: to assume much less about price, and extra about worth.”

Diversifying the provision chain past a handful of suppliers will increase resilience, decreasing susceptibility to cyberattacks. It additionally helps speed up growth instances and enhance the sustainability of essential supplies.

For instance, British engine producer Rolls-Royce has partnered with the MoD to transform retired Royal Air Pressure (RAF) Twister fighter jet elements into new steel feedstock. The undertaking, dubbed Twister 2 Tempest, goals to construct a round materials provide chain.

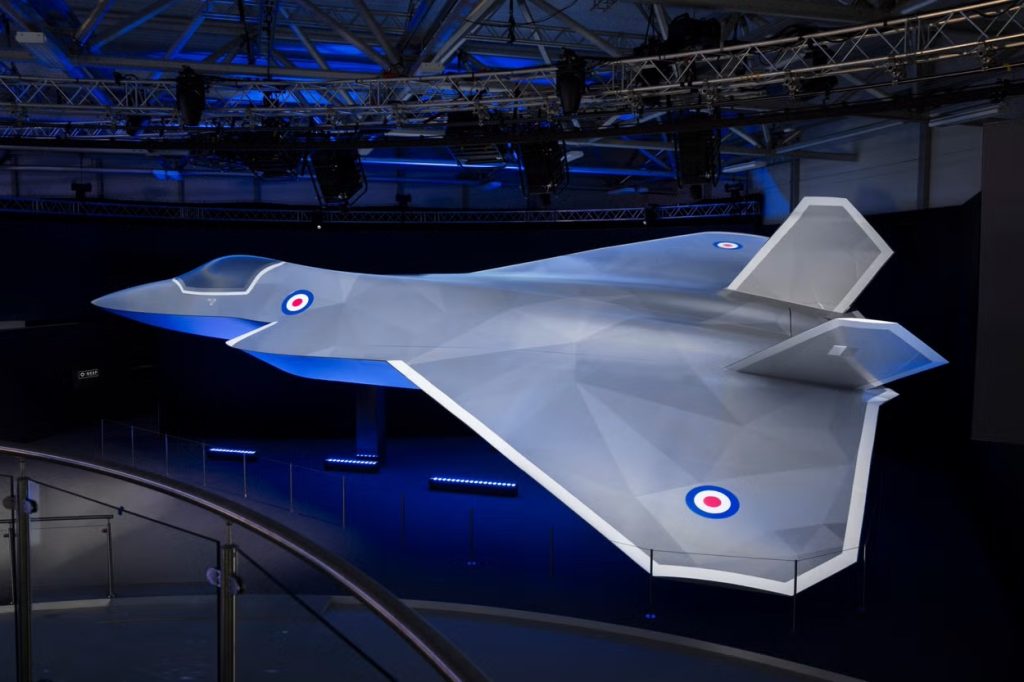

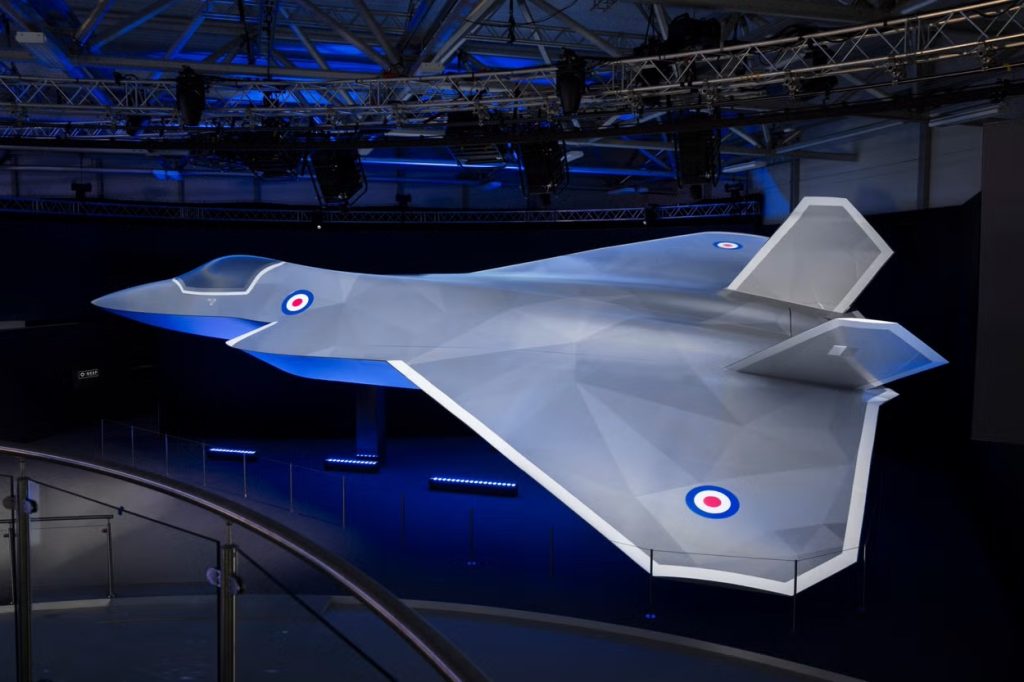

Defence officers are exploring whether or not this recycled steel will be atomized into powder to be used in Britain’s Tempest next-generation fighter jet. Additive manufacturing already performs a key function in Tempest’s growth. BAE Methods, creating the brand new fighter jet beneath the World Fight Air (GCAP), goals to 3D print 30% of the plane’s elements. Tempest’s supersonic demonstrator already contains structural parts produced with additive manufacturing.

How is 3D printing used within the British navy?

Within the discipline, expeditionary 3D printers maintain British forces battle-ready longer by delivering spare elements sooner and nearer to the purpose of want. These elements don’t should be top-tier, licensed parts, simply “sufficient to get us again within the combat for the subsequent two or three rounds of battle,” as McMahon put it. He described this operational functionality as “invaluable” for troopers on the entrance line.

Given these benefits, additive manufacturing is shortly gaining traction inside the British navy. What started with particular person models experimenting with desktop FDM 3D printers has grown into an built-in functionality throughout forces working on land, sea, and within the air.

Within the Military, McMahon pointed to the Royal Electrical and Mechanical Engineers’ 5 and 9 Battalions, that are deploying additive manufacturing to provide elements in assist of Ukraine.

Final yr, 9 Theatre Help Battalion (9 REME) took half in Additive Manufacturing Village 2024, a European Defence Company showcase held in Belgium. British troops collaborated with Ukrainian counterparts to 3D print 133 purposeful elements on the occasion. Of those, 20 have been produced from steel. In addition they created technical knowledge packs (TDPs) containing the digital data wanted to 3D print 70 completely different spare elements.

2024 additionally noticed 9 REME deploy its additive manufacturing capabilities throughout Train Steadfast Defender, NATO’s largest navy train because the Chilly Conflict. 9 REME personnel operated an XSPEE3D steel cold-spray 3D printer from Australian agency SPEE3D. They produced a number of spare elements, together with jerry can caps, communication brackets, and engine bay mounts for getting old autos.

Throughout a separate panel dialogue at TCT 3Sixty, Richard Hamber, the MoD’s Innovation AdM Lead, revealed that the British Military’s Particular Air Service (SAS) makes use of 3D printing to assist its covert operations. Particulars are restricted, however Hamber confirmed that the SAS 3D prints “fully distinctive” polymer elements at its Stirling Traces garrison in Hereford.

Within the Royal Air Pressure, 71 Inspection and Restore (IR) Squadron runs a number of steel 3D printers out of RAF Wittering to readily fabricate aerospace elements. Working beneath Mission Warhol, the RAF’s AM initiative, 71 IR Squadron possesses Wayland Additive Calibur3 NeuBeam, Renishaw RenAM 500 steel LPBF, and Stratasys Fortus 450 FDM 3D printers, together with a Nikon HTX 540 CT scanner. Based on McMahon, these methods are used to quickly produce elements to conduct repairs, testing, and trials.

In the meantime, the MoD’s Submarine Supply Company is 3D printing elements for the subsequent technology class of Dreadnought submarines. A few of these parts are additionally being retrofitted into the prevailing Astute-class submarines. Based on the MoD’s Superior Manufacturing Technique, additive manufacturing can be being leveraged to assist the SDA’s In Service Submarines (ISS) and Ship Submersible Nuclear (Assault) (SSN(A)) programmes.

Elsewhere, the Atomic Weapons Institution (AWE) is utilizing 3D printing to provide complicated elements. Equally, the MoD’s Protection Gear & Help (DE&S) Defence Electronics and Parts Company (DECA) makes use of 3D printing to make prototypes.

Business partnerships are central to growing adoption throughout the protection ecosystem. The MoD is working carefully with the Excessive Worth Manufacturing Catapult to develop strategic alliances and stimulate demand alerts to information UK business.

Worldwide collaboration is gathering tempo, with the 2025 Defence Assessment setting out the UK’s new ‘NATO First’ ambition. The MoD is actively concerned in a number of NATO additive manufacturing (AM) initiatives. One initiative, led by McMahon since final yr, brings collectively 12 member nations to discover partnerships and advance NATO’s AM capabilities. Sweden is the primary member nation to completely share particulars of its AM efforts. Based on McMahon, these carefully align with the UK’s factory-to-foxhole imaginative and prescient.

Additional interoperability testing is underway. The continued Coalition Warrior Interoperability Train (CWIX) contains an AM thread, testing NATO’s Speedy E digital repository for securely storing and sharing AM knowledge packs.

Mission TAMPA: Profitable “hearts and minds” in manufacturing

Behind the British navy’s 3D printing efforts is Mission TAMPA. Launched in 2021, this MoD initiative seeks to speed up the adoption of additive manufacturing inside the UK’s protection provide chain.

“Mission Tampa is a change programme, not a know-how programme,” defined McMahon. He highlighted the urgent must “change the hearts and minds” of 3D printing skeptics inside the provide chain.

Structured in 4 spirals of accelerating complexity, Mission Tampa is designed to show additive manufacturing from an experimental functionality into “enterprise as traditional.” Its early outcomes present the strategy is working.

In Spiral One, MoD suppliers Babcock, NP Aerospace, Rheinmetall BAE Methods Land (RBSL), Thales, and AMFG developed non-safety essential elements to show that additive manufacturing can assist real-world defence purposes. One in every of which, an L118 mild gun towing eye shaft, is now an formally demandable stock merchandise.

Developed by Babcock, the 3D printable half has been permitted to be used in fight operations and will be ordered via Babcock’s Materials Availability Service. “It’s not only a science experiment,” McMahon burdened. “It’s delivering operational impact.”

Spiral Two, at the moment 50% full, focuses on safety-critical parts. This contains 3D printed Challenger 2 and Challenger 3 tank parts developed by RBSL. These elements face stricter certification calls for however are on observe to enter service.

Spiral Three goals to show that elements will be manufactured equivalently throughout a world provide chain, with efforts throughout the UK and the US. The awardees embody Babcock, NP Aerospace, RBSL, and Thales. America Division of Protection (DOD) is operating a parallel program known as Allied Additive Manufacturing Interoperability (AAMI).

Wanting forward, McMahon confirmed that Mission TAMPA won’t proceed after spiral 4. The final word objective is to not develop extra demonstration elements, however to ascertain a procurement and governance system that permits elements to be delivered to the MoD at scale. The programme’s remaining section will create a pre-competed framework enabling firms to deliver elements instantly into defence with out bureaucratic hurdles.

Collaboration is vital to Tampa’s philosophy. Each stage of the undertaking’s governance, from working teams to government committees, has an business co-chair with authority to affect selections. “This isn’t defence telling business what we would like,” stated McMahon. “That is defence asking business, how will we do that higher?”

One essential issue is accelerating certification. It took 18 months from Spiral One’s begin to having an authorized half in stock. The largest hurdle, McMahon admitted, was not the certification course of itself, however overcoming scepticism contained in the MoD.

A breakthrough got here when the Certification Working Group appointed an airworthiness professional as co-chair, bringing expertise in each Nationwide Aviation Authority (NAA) and defence certification. “As a result of he understands the method, we are able to use him to unlock skeptics once they say, ‘We don’t perceive this,’” McMahon defined.

The RAF Wing Commander likened this shift to the acceptance of composite supplies a long time in the past. “Thirty or forty years in the past, after we have been coping with carbons and Kevlars and fibreglass composites, individuals didn’t perceive it,” McMahon defined. “There was materials science to beat then. There’s much less materials science to AM.”

Due to this fact, for the MoD, the way forward for 3D printing hinges much less on know-how and extra on mindset. Its newest hearts and minds marketing campaign gained’t be waged on the battlefield, however on the manufacturing facility ground.

Be part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, Area, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

You may also observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals Wing Commander Jon McMahon talking at TCT 3Sixty 2025. Picture by 3D Printing Business.